Silica Ramming Mass

Get Price Quote

56 Ton (MOQ)

Our silica or acidic ramming mass is prepared using the best raw material, latest technology and under supervision of trained staff. We prepare material in both quartz and quartzite. We prepare the material for induction furnaces having capacity from 0.5 - 40 tons.

Silica Ramming Mass

2,800 - 3,500 Per Metric Ton

20 Metric Ton (MOQ)

Best Deals from Silica Ramming Mass

Silica Ramming Mass

Get Price Quote

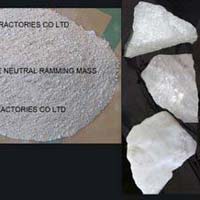

A white coloured substance, the Silica Ramming Mass is in high demand. As one of the most trusted manufacturer of this product, we also supply and export it to many of our clients from all parts of the world. The rates at which we offer this product are extremely nominal and market leading as well. Our happy clients are our foremost concern and we ensure satisfaction in each deal. Features : It is Good resistance to temperature change,Low cost in furnace lining. Short heating and sintering time through dry preparation Of masses. The price is very attractive compared to others. Silica ramming mass can safely be used up to an operating temperature of 1600°C it expands very little so it is superior to both alumina and magnesia to resist thermal shocks. Secondly its cost is very low in comparison to alumina and magnesia. Silica can be used for melting copper and copper alloys including cupronickels with change in amount of binding agent additions. For brasses melting silica lining is the “ideal “choice Granulometric composition of commercial silica ramming mass. Size Percentage : 4mm to 1mm 33% 1mm to 0.20mm 30% 0.20mm to0.06mm 17% 0.06mm & below 20%

Silica Ramming Mass

Get Price Quote

The company is engaged in the manufacturing, supplying and exporting of Silica Ramming Mass. We ensure the purity of Silica Ramming Mass. The company is expertise in checking the composition of Silica Ramming Mass before supplying to our clients. Silica Ramming Mass is used in induction furnace made of steel billets and ingots. Why our Silica Ramming Mass? Ensures smooth working Excellent corrosion resistance High thermal stability Moisture free

Silica Ramming Mass

Get Price Quote

The Silica Ramming Mass we offer is of high purity. The Silica Ramming Mass is resistant to abrasion and spalling. We bring superior quality Silica Ramming Mass which is acidic in nature having the melting point 3274 F. Our Silica Ramming Mass is widely used in the lining of induction furnaces. Our superior quality Silica Ramming Mass is stringently manufactured under strict supervision of qualified and experienced work force. Proper check is exercised on magnetic process to assure iron free Silica Ramming Mass and to assure proper composition of granules according to furnace capacity. Relevant Details Nature - AcidicMelting Point - 3274oF (1700oC) Use In the lining of induction furnaces - Quality of acidic ramming mass is directly related to the heating performance of the furnaces. Better quality of lining results in the smooth working of furnaces, optimum output and better metallurgical control. Granulometric Composition Of Commercial Silica Ramming Mass Size Percentage 1 mm to 4 mm 33 %1 mm to 0.20 mm 30 %0.20 mm to 0.06 mm 17 %0.06mm & Below 20 %

Silica Ramming Mass

Get Price Quote

Silica Ramming Mass, Packed Ramming Mass, Premixed Ramming Mass, Quartz Dust

Silica Ramming Mass

Get Price Quote

Silica Ramming Mass, Acidic Ramming Mass, Calcite Powder, Feldspar Powder

Silica Ramming Mass

Get Price Quote

Silica Ramming Mass, Ball Clay, Micro Silica, Mica Powder, Garnet Sand