Silica Ramming Mass

2,800 - 3,500 Per Metric Ton

20 Metric Ton (MOQ)

Silica Ramming Mass

Get Price Quote

56 Ton (MOQ)

Our silica or acidic ramming mass is prepared using the best raw material, latest technology and under supervision of trained staff. We prepare material in both quartz and quartzite. We prepare the material for induction furnaces having capacity from 0.5 - 40 tons.

Best Deals from Silica Ramming Mass

Silica Ramming Mass

Get Price Quote

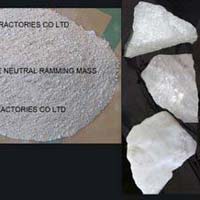

A white coloured substance, the Silica Ramming Mass is in high demand. As one of the most trusted manufacturer of this product, we also supply and export it to many of our clients from all parts of the world. The rates at which we offer this product are extremely nominal and market leading as well. Our happy clients are our foremost concern and we ensure satisfaction in each deal. Features : It is Good resistance to temperature change,Low cost in furnace lining. Short heating and sintering time through dry preparation Of masses. The price is very attractive compared to others. Silica ramming mass can safely be used up to an operating temperature of 1600°C it expands very little so it is superior to both alumina and magnesia to resist thermal shocks. Secondly its cost is very low in comparison to alumina and magnesia. Silica can be used for melting copper and copper alloys including cupronickels with change in amount of binding agent additions. For brasses melting silica lining is the “ideal “choice Granulometric composition of commercial silica ramming mass. Size Percentage : 4mm to 1mm 33% 1mm to 0.20mm 30% 0.20mm to0.06mm 17% 0.06mm & below 20%

Acidic Silica Ramming Mass

Get Price Quote

We are a renowned Manufacturer, Supplier and Exporter of Acidic Silica Ramming Mass. We have well-equipped production units for the processing of Acidic Slica. The packaging is done in sealed containers to prevent its contamination. We make use of quality raw materials for the processing of Acidic Slica. We offer Acidic Slica at the most nominal prices and assure timely delivery. Details : Granulometric Composition Of Commercial Silica Ramming Mass Size Percentage : 4 mm to 1 mm 33%, 1 mm to 0.20 mm 30%, 0.20 mm to 0.06 mm 17%, 0.06mm & Below 20%Our Acidic Ramming Mass is manufactured under strict supervision of qualified and experienced work force. Proper check is exercised on magnetic process to assure iron free Acidic Ramming Mass and to assure proper composition of granules according to furnace capacity. Furnace Specific Benefits: We are the only manufacturer to give material as per the furnace capacity and make of the user. The granulation of the mix are optimized keeping in view the furnace make and capacity, thus giving maximum and best results. Ramming mix is characterized by thermal stability, corrosion resistance and wear resistance because it contains less binders, fire clay and moisture compared to plastic refractories. Recommended for lining the iron melting coreless induction furnace. Premixed with binder to customer's specifications. Maximum recommended use limit- 3200°F (1700°C)

Silica Ramming Mass

Get Price Quote

we are One of the Leading White silica Ramming Mass Manufacturers Based in India. Silica Ramming Mass is a Dry Lining Refractory that Can Be Used for all Types of Iron and Steel and in Both Mini Steel Plants as Well as Foundries. Acidic Silica Ramming Mass is Used in all Types of Induction Furnaces as a Refractory and Furnace Lining for Coreless Induction Furnace, as Insulation Material to Prevent the Coil from the Metal ramming Mix is Characterized By Thermal Stability, Corrosion Resistance and Wear Resistance Because It Contains Less Binders, Fire Clay and Moisture Compared to Plastic Refractories. in Vikram Minerals, Ramming Mass is Manufactured Under Completely Controlled Conditions and the Formulation is Prepared with Consultations of Major Furnace Manufacturers. It is Best Suited to Control: reactivity of the Refractory temperature in Which Reactivity Takes Place sintering Characteristics of the Lining density and Strength of the Lining we are Manufacturing Ramming Mass to Give Material as per the Furnace Capacity and Make of the User. the Granulations of the Mix are Optimized Keeping in View the Furnace Make and Capacity, Thus Giving Maximum and Best Results.

Silica Ramming Mass

Get Price Quote

We are into the producing and offering of the best quality Silica Ramming Mass to our most esteemed customers. We offer two different types of ramming mass to our customers they are post mix and pre mix. This product is of pure white colour. It is produced with the help supreme quality raw materials. The customers are more than delighted with the quality and intend to purchase more of it. Details : 4 mm to 1 mm 33 % 1 mm to 0.20 mm 30 % 0.20 mm to 0.06 mm 17 % 0.06mm & Below 20 % Boric Acide 1.2% Applications : Steel industry Paper industry Sanitary ware industry Chemical industry

Silica Ramming Mass

Get Price Quote

The company is engaged in the manufacturing, supplying and exporting of Silica Ramming Mass. We ensure the purity of Silica Ramming Mass. The company is expertise in checking the composition of Silica Ramming Mass before supplying to our clients. Silica Ramming Mass is used in induction furnace made of steel billets and ingots. Why our Silica Ramming Mass? Ensures smooth working Excellent corrosion resistance High thermal stability Moisture free

Silica Ramming Mass

Get Price Quote

We are supported by an advanced packaging system and make use of only high quality packing materials for ensuring complete safety during handling, warehousing and transit. Our team of quality experts strictly checks the entire range against varied parameters to make sure that they adhere to global quality standards. Premixed Ramming Mass : We have been the leaders in promoting premixed use in big capacity induction furnaces. Our all the grades are available in premixed versions also. Premixed gives the following benefits to the user: Proper mixing of binder leading to optimum mixture. Less wastage, as mixing is done by machines. Only use imported Boric Acid is used to give best results. Consistent and longer lining and patching life. One less item in inventory. Salient Features High Purity High Refractoriness High Spalling Resistance High Abrasion Resistance High Resistance to Cracking Freedom from iron Low Sintering time Silica Ramming Mass Mixes Nature - Acidic Melting - 3274°F (1700°C) Acidic ramming mass is used in the lining of induction furnaces. Quality of acidic ramming mass is directly related to the heating performance of the furnaces. Better quality of lining results in the smooth working of furnaces, optimum output and better metallurgical control. Granulometric composition of commercial silica ramming mass size percentage: 4 mm to 1 mm 33 % 1 mm to 0.20 mm 30 % 0.20 mm to 0.06 mm 17 % 0.06mm & Below 20 % Our superior quality acidic ramming mass is stringently manufactured under strict supervision of qualified and experienced work force. Proper check is exercised on magnetic process to assure iron free Acidic ramming mass and to assure proper composition of granules according to furnace capacity. FURNACE SPECIFIC BENFITS: We are the only far-famed manufacturer to give material as per the furnace capacity and make of the user. The granulation of the mix is optimized keeping in view the furnace make and capacity, thus giving maximum and best results. Ramming mix is strictly characterized by thermal stability, corrosion resistance and wears resistance because it contains less binders, fire clay and moisture compared to plastic refractory. Recommended for lining the iron melting coreless induction furnace. Premixed with binder to customer's specifications. Maximum recommended use limit- 3274°F (1700°C). Grades of Ramming Mass : We are the one of the manufacturer who provides material as per the furnace capacity and make of the user. The granulations of the mix are optimized keeping in view the furnace make and capacity, thus giving maximum and best results.Keeping in view the different needs, different types of scraps, end products and several other factors, we have got different grades: Normal: This is the widely used grade of Silica Ramming Mix. Silica content here is in the range of 98.50 % to 99 %. This is the cheapest grade available. But performance is the best in its category. Normal Premix: This is the pre mixed version. We mix Boric Acid as per customer requirements, although most common in India is 1.1 %. Recommended for lining the iron melting coreless induction furnace.

Silica Ramming Mass

Get Price Quote

Silica Ramming Mass

Get Price Quote

We Offer quality Silica Ramming Mass Powder which is made from quality base materials. The Silica Ramming Mass Powder is highly acclaimed for its fine texture and purity among the clients and has attracted them to place repeated orders. We offer Silica Ramming Mass Powder at affordable price. Used At : Lining of Induction furnaces Properties : Super snow white crystalline quartz, 4 Mesh-finer Bulk Density : 2-2.2ton/m3 Softening point : 1280oC Specifications : SiO2 : upto 99.90% Al2O3 : 0.02% Iron Content : Nil

Silica Ramming Mass

Get Price Quote

Sun minerals acidic silica ramming mass is used in the lining of induction furnaces. Quality of acidic ramming mass is directly related to the heating performance of the furnaces. Better quality of lining results in the smooth working of furnaces, optimum output and better metallurgical control. It is manufactured under strict supervision of qualified & experienced work force.

Silica Ramming Mass

Get Price Quote

The Silica Ramming Mass we offer is of high purity. The Silica Ramming Mass is resistant to abrasion and spalling. We bring superior quality Silica Ramming Mass which is acidic in nature having the melting point 3274 F. Our Silica Ramming Mass is widely used in the lining of induction furnaces. Our superior quality Silica Ramming Mass is stringently manufactured under strict supervision of qualified and experienced work force. Proper check is exercised on magnetic process to assure iron free Silica Ramming Mass and to assure proper composition of granules according to furnace capacity. Relevant Details Nature - AcidicMelting Point - 3274oF (1700oC) Use In the lining of induction furnaces - Quality of acidic ramming mass is directly related to the heating performance of the furnaces. Better quality of lining results in the smooth working of furnaces, optimum output and better metallurgical control. Granulometric Composition Of Commercial Silica Ramming Mass Size Percentage 1 mm to 4 mm 33 %1 mm to 0.20 mm 30 %0.20 mm to 0.06 mm 17 %0.06mm & Below 20 %

Silica Ramming Mass

Get Price Quote

silica quartz powder, Feldspar, Acidic Ramming Mass, Ramming Mass, Silica

Silica Ramming Mass

Get Price Quote

Soapstone

Silica Ramming Mass

Get Price Quote

Quartz Minerals, Mica

Silica Ramming Mass

Get Price Quote

quartz silica grain, Pyrophyllite Powder, Feldspar, China Clay Powder

Silica Ramming Mass

Get Price Quote

Premix Silica Ramming Mass, Acidic Ramming Mass

Silica Ramming Mass

Get Price Quote

Packed Ramming Mass, Premixed Ramming Mass, Quartz Dust, Quartz Grains

Silica Ramming Mass

Get Price Quote

Ball Clay, Micro Silica, Garnet Sand, Feldspar Powder

Silica Ramming Mass

Get Price Quote

Silica, Potash Feldspar, Acidic Ramming Mass, soda & potash feldspar

Silica Ramming Mass

Get Price Quote

Acidic Ramming Mass, Feldspar Powder