Semi Automatic Weighing Filling Machine

18,000 - 85,000 Per Box

Automatic Check Weigher Machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Automatic Weighing Machine

Automatic Weighing and Bagging Machine

Get Price Quote

Automatic Weighing and Bagging Machine

400,000 Per Piece

1 Piece (MOQ)

Primetech Engineering offers complete solutions in Bagging and weighing systems for Bulk Material Handling. We provide a complete end to end solution right from concept to commissioning for any kind of process applications. We offer a complete package solution with Fully Automatic/Semi-Automatic & Manual operation.Following are range machines, Jumbo Bag Filling Machine Bag Filling Machine Valve Bag Filling Machine Conveyor and Hopper based Bag filling systems Jumbo Bag Unloading system Drum Filling Machine Any kind of customized application for Bulk Handling systems Areas Of Application Chemical Powder & Granules Cement, Fly ash and Limestone Fertilizers, Sugar and Salts Minerals and Construction material Oil and Liquid Grains and Animal feed stock Sludge and Slag handling

Semi Automatic Weighing Operated Liquid Filling Machine

Get Price Quote

1 piece (MOQ)

semi automatic weighing machine

19,000 - 20,000 Per

1 Box (MOQ)

Hualian Brand SS304 Semi Automatic Weigh filler Partical and powder filler machine 1-100gm digital panel machine. With 1 year warranty

Weight Filler Automatic Pouch Packing Machine

90,000 Per Piece

1 Piece (MOQ)

Phoenics Automatic Height Weight Scale

20,000 Per Piece

Automatic Weighing Machine

900,000 - 1,200,000 Per Piece

1 Piece (MOQ)

1gm- 100gm Automatic Weighing and Pouch Packing Machine

78,000 Per Piece

1 Piece (MOQ)

Fully Automatic Electronic Digital Weighing Scale

2,500 Per Piece

10 Piece (MOQ)

automatic weighing machines

Get Price Quote

Packing range 10gm. To 1kg filling system : weigh filler (available all filling systems) type of sealing : center seal packing material : powder, grains, etc film size : 250mm-800mm width x 100mm-650mm length film roll type : laminated film in roll supported film e.g. Aluminum foil pe, pp speed : 14 to 30 bagmin (varies with the nature of product & depend on filling line like single head to four head) power : 4 kw 230v ac single phase 50hz

Stesalit Continuous Weigher (SCW) (BELT WEIGHER) (Weighing Machine)

Get Price Quote

Presently Tea Industry totally depends on old age technology based on batching systems for getting the tea made records which is not very reliable and huge complaint of frequent breakdowns are observed in many tea factories. TO OVERCOME this problem, Stesalit has introduced universally accepted Dynamic method for all event monitoring data of Dryer output. System Overview Stesalit Continuous Weigher (SCW) is uniquely designed for online continuous monitoring of tea made output from dryers. It is basically an electronically and sensor controlled specially designed belt weigher and can be easily placed in between dryer and sorting zone. It continuously records and displays all the events like cumulative output, total operation time, power cut time etc. This helps to monitor the productivity of the whole process at any instant. Salient Features Advantage Online display of current events like total operation time, power cut time and cumulative output Detailed event recording of individual batch for past 64 batches of all parameters with date and time Elaborate self diagnostics to detect the exact area of problems to get instant solution Easy and well defined calibration procedures for smooth and steady operation In case of power failure it starts automatically after one minute of power restoration All the parts come in contact with tea made are food grade stainless steel It can be linked with computer for remote monitoring of Stesalit Continuous Weigher (SCW) operation (optional) Different models are available from 300 kgs tea madehour to 1500 kgs tea madehour Dimension: L-1900mm x H-1200mm x W-970mm

SIMPLEX WEIGHING MACHINE

340,000 - 500,000 Per piece

1 machine (MOQ)

Simplex Weighing Machine's weighing range is 25 kg - 100 kg and the out put is 450 bags - 500 bags/hr.The accuracy is +/- 20 grams. Depens on the flow character of material. Techinical Specifications: *Latest IMPORTED Micro-Procesor Based controller exclusively made for Hi-Tech Engineers Firm. *Higher samping speed up to 1000 samples per second. *Auto Zero and Auto Tare Function. *Programmable Auto In - Flight Control Correction. *Alarm for over / under weighment. *Error message and Diagnostic function. *Optional standard deviation calculator. *Modbus RTU communications,easily connectable to existing DCS. *Communication: Standard - RS 232. *Optional:Modbus / Profibus / Ethernet.

automatic scales

2,999 - 3,999 Per Piece

1 piece (MOQ)

Semi Automatic Weighing Machines(100g-1000g)

43,200 Per Set

1 Set(s) (MOQ)

semi -automatic weighing machines(100g-1000g)size :40*60*120cm,weight : 35kg.

Automatic Weighing Machine

Get Price Quote

model vtc-vgfp-1.1 is a digital load cell based auto weighing and packing machine controlled by micro-processor based controller. It is suitable for packing granules and powder products like, chemicals, fertilizer, sugar, rice, food grains, pulses, spices, salt, groundnut, sabudana, atta, maida, rava, namkeen, tea, etc. operation of the machine the machine to be fitted below the storage hopper. Material flows with the help of vibratory tray into the damper. on initiating the system flap opens and material falls into the load based weighing hopper. as soon as 90 % of the weight is reached flap closes & fine feed starts filling till the target weight is reached. the gate provided below the weighing hopper opens and the material falls into the bag the continuous sealer provided beside the machine with the help sealer you can pack. salient features of the machine auto filling and weighing electronic microprocessor controlled machine machine can be used for variety of granules materials like spices-granules & powder product. small and compact machine easy to operate and maintain

Automatic Weight Filling Machine

Get Price Quote

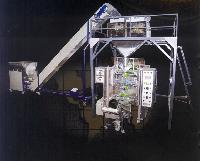

Fully Automatic VFFS Machine with Weigher Conveyer

Get Price Quote

The company is a renowned Exporter and Supplier of Fully Automatic VFFS Machine with Weigher Conveyer in Delhi. The Fully Automatic VFFS Machine with Weigher Conveyer is highly suited for the packing processes and offers unmatched performance levels. The company offers the very best Fully Automatic VFFS Machine with Weigher Conveyer to the clients. Fully Automatic Form Fill Seal machine is suitable to pack Powder & Granules such as Tea, Coffee Powder, Coffee Beans. Tobacco, Whole spices, Seeds, Rice, Pulses, Namkeen, Snacks, Toffee, Sweets, Henna Powder, Milk Powder, Nuts, Pesticide, Fertilizer granules, Shampoo, Oil, Spirits, Ketchup, Chemicals, Wine etc.

semi automatic weighing machine

Get Price Quote

The Weigh Filling Machine is employed packing free flowing powders.Filling Accuracy : Up to ± 1% for most of the material at constant material,Operating Speed : 500 to 1200 Filling hr. (Depending on packing size).