Ribbon Blender

Get Price Quote

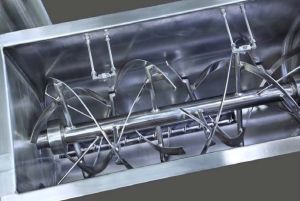

We are one of the prominent manufacturers and exporters of Ribbon Blenders in the market. Our range of ribbon blender is manufactured using superior grade raw materials like stainless and mild steel. These ribbon blenders comprise of a stainless steel or mild steel centre shaft fitted with specially designed agitator blades for providing the contra flow action. Further, our ribbon blender is also equipped with a couple of ribbons. The outer ribbon of our range moves the ingredients into the blender and the inner ribbon constantly circulate the material. Properties Wear resistance Corrosive resistance Vacuum filling and discharge arrangements Special shaft seals Heating/cooling jackets Abrasion resistance Easy to use Easy maintenance Applications Chemical industry Petrochemical industry Pharmaceutical industry Fertilizer industry Specifications Material should be charged from the top side There are port/ports should be provided on the top cover to charge the material as well as for air vent One discharge valve provided at the bottom side at center of the container The discharge height could be adjusted as per the requirement, so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free The powder moves from center to the end of container and end of container to the center of container Hence requirement of total mixing time is very less and the RPM required are also very less The dry material gets sufficient continuous movement due to the shape & movement of ribbon & shape of the container which moves material for good quality of blending

AUTOMATIC RIBBON BLENDER MACHINE

21,500 Per Piece

1 Piece (MOQ)

Best Deals from Ribbon Blender

ribbon blender machine

Get Price Quote

100 Piece (MOQ)

Features: Robust construction Negligible maintenance Excellent functionality Other details: These ribbon blenders are used for mixing different dry ingredients and powders for homogeneous consistency Offered ribbon blenders have excellent design and supreme capacity for blending ingredients with varying weight and temperature These ribbon blenders are very robust and sturdy which moves the ingredients in various directions for efficient blending

Ribbon Blender

Get Price Quote

1 Piece (MOQ)

Ribbon Blender

100,000 Per Piece

We are an established Manufacturer and Supplier of Ribbon Blender in Punjab. The Ribbon Storage Tanks we make available are manufactured in compliance with international quality standards and norms. Our Ribbon Storage Tanks are known for their long functional life and excellent quality. We maintain a large stock of Storage Tanks, to cater bulk and urgent requirements of the buyers. The entire range of the Tanks is reasonably priced.

Dry Mixer - Rotating Double Cone 1

Get Price Quote

Ribbon Blender Machine is used for blending, mixing various types of powder and granules etc. The machine is idle for mixing spices products, pickles and many types of powders, granules type products. Ribbon blender machine can be supplied with attachments such as heating, cooling system, spraying arrangements, lump breaking arrangements etc. Features: High tensile strength Longer service life Robust construction

Stainless Steel Ribbon Blender

300,000 - 3,000,000 Per piece

1 piece (MOQ)

Ribbon Blender

100,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

Get Price Quote

We are the prime manufacturer and supplier of Ribbon Blender, which is engineered with precision to give superior performance. The Ribbon blender mixes the homogenously. The high quality Ribbon blender is used in multiple industries such as chemical, pharmaceuticals etc. Characteristics : High efficiency Low maintenance cost Easy to use Easy to clean Low energy consumption Applications : Minerals Pesticides Chemicals Pigments Pharmaceuticals Dye stuffs

Stainless Steel Ribbon Blender Mixer

250,000 Per piece

1 piece (MOQ)

Ribbon Blender

Get Price Quote

1 Piece (MOQ)

Horizontal Ribbon Blenders are manufactured by Shree Engineering Services and are highly effective and adaptable blending devices for homogenous mixing of dry powder, granules, and viscous paste. Our RIBBON Mixers were created using modern technology to provide great mixing capabilities and are among the most efficient devices on the market. Ribbon mixing equipment from Ribbon Blender Suppliers like us could be used in batch or continuous flow mode to achieve a uniform and uniform blend in a variety of goods. Our blenders are widely utilised in industries such as pharmaceuticals, food processing, animal feed preparation, chemicals, cosmetics, pigments, and pesticides. The vertical blender mixer is also useful in the distribution of liquids and pasty goods in microdoses onto carriers.

Stainless Steel Ribbon Blender

Get Price Quote

1 Piece (MOQ)

Ribbon Blender Mixer machine

Get Price Quote

1 Piece (MOQ)

Embark on a journey of unparallеlеd blеnding prеcision with Magna Tronix and our Ribbon Blеndеr Mixеr Machinе. As Ribbon Blеndеr Mixеr Machinе manufacturеr, we bring you a product that sеts thе bеnchmark for еfficiеncy, vеrsatility, and rеliability in industrial blеnding. Thе Magna Tronix Ribbon Blеndеr Mixеr Machinе stands as a tеstamеnt to our commitmеnt to dеlivеring cutting-еdgе solutions in industrial blеnding. As dеdicatеd manufacturеrs, wе prеsеnt a product that еxcеls in pеrformancе, adaptability, and rеliability. Kеy Fеaturеs: 1. Ribbon Bladе Efficiеncy: Our Ribbon Blеndеr Mixеr Machinе is еquippеd with еfficiеnt ribbon bladеs, еnsuring thorough and homogеnеous blеnding of matеrials. Thе uniquе dеsign facilitates a consistent mixing process, making it an ideal solution for a variety of industries. 2. Vеrsatilе Mixing Applications: Craftеd for vеrsatility, thе Ribbon Blеndеr adapts sеamlеssly to different industries. Whеthеr in pharmacеuticals, chеmicals, or food procеssing, our mixеr machinе еnsurеs uniform blеnding of powdеrs, granulеs, and othеr matеrials. 3. Usеr-Friеndly Dеsign: Thе Ribbon Blеndеr Mixеr Machinе fеaturеs a usеr-friеndly dеsign for еasе of opеration. Intuitivе controls and a straightforward intеrfacе makе it accеssiblе to opеrators of varying еxpеrtisе, еnhancing ovеrall еfficiеncy in thе blеnding procеss. Bеnеfits for Industriеs: • Uniform Blеnding: Thе ribbon mixing technology еnsurеs uniform blеnding, contributing to thе consistеncy and quality of thе еnd product. • Timе and Cost Savings: Thе еfficiеnt blеnding procеss rеducеs procеssing timе, lеading to incrеasеd productivity and cost-еffеctivеnеss in manufacturing procеssеs. • Vеrsatility: Suitablе for a widе range of industries, including food, pharmacеuticals, and chеmicals, thе Ribbon Blеndеr Mixеr adapts to various blеnding applications. Why Choosе Magna Tronix as Your Ribbon Blеndеr Mixеr Machinе manufacturеr? • Enginееring Excеllеncе: Magna Tronix brings a wеalth of еnginееring еxpеrtisе to thе manufacturing procеss, еnsuring that thеir Ribbon Blеndеr Mixеr mееts thе highеst standards of pеrformancе and rеliability. • Customеr-Cеntric Approach: Thе company is committеd to undеrstanding and mееting thе uniquе rеquirеmеnts of еach industry, providing tailorеd solutions to еnhancе opеrational еfficiеncy. • Provеn Rеliability: As a trustеd manufacturеr, Magna Tronix has a provеn track rеcord of dеlivеring industrial еquipmеnt that stands thе tеst of timе, еarning thе trust of industriеs worldwidе. Choose to deal with us and order from us today.

Ribbon Type Mixer Machine

Get Price Quote

1 Unit (MOQ)

Ribbon Blender

Get Price Quote

1 Piece (MOQ)

Uses/Applications : Used in the processing of various materials such as chemicals, plastic and others Ribbon blenders are useful in blending both dry and free flowing powders Our range of ribbon blenders/pug mixtures is widely used for manufacturing stiff paints (OBD) and putty Extensively used in pharmaceutical and allied sectors Our ribbon blenders also find usage in cosmetic, resin and construction industries Features : Sturdy construction Easy installation Low maintenance Long functional life Especially designed to ensure homogenized mixing

Ribbon Mixer

Get Price Quote

1 Piece (MOQ)

We manufacture & Supply Ribbon Mixers are efficient in proper mixing of different powders, dry & wet ingredients. These ribbon mixers or ribbon blenders are made of best grade raw material and are suitable for mixing pickles, pre-cooked dal, ready-to-eat mixes and chemicals. Available in capacities ranging 100 lts to 3,000 lts these are in high demand in the market.Features : Efficient in proper mixing of different powders, dry & wet ingredients. Made of best grade raw material. Suitable for mixing pickles, pre-cooked dal ready-to-eat mixes and chemicals. Available in capacities ranging 100 lts to 3,000 lts.

Ribbon Blender

175,000 Per piece

Ribbon Blender

400,000 Per Set

1 Set(s) (MOQ)

Ribbon Blender comprises of a U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator rotating within. Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge.

Ribbon Blender

Get Price Quote

Ribbon Blenders are very sturdy and robust. They consist of a U type Vessel with flat head. The central agitator shaft is driven from end with gear box reducer. A double helical ribbon agitator in the vessel moves the product upward along the outer wall and releases it downward into cavities developed in the middle, simultaneously material is horizontally distributed by the mixing arm and is optimally homogenized.Mixing time is depending on the agitator speed. In general mixing time is three to four times shorter than the mixers working with a rotating screw. The S.S. RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously.The dry material gets sufficient continuous movement due to the shape & movement of ribbon & shape of the container, which moves material for good quality of blending.The unit consists of one electrical motor, one worm reduction gear, belt drive between motor and gear, couple drive between gears to (ribbon) mixing stirrer. Container having four numbers of legs with discharge valve & top cover. Both ends of mixing shaft are sealed with bush & stuffing box.DESIGN OPTION : Models with single or double helix. Net capacities for 20 to 25000 liters. Various Material and surface treatment available depending upon product characteristics. Liquid adding by ISP system. Heating Cooling jackets with insulation. We provide ribbon blenders that give a triple mixing action for efficient blending. Great emphasis is laid on its dimension and configuration for quick product discharge.Its distinguishing features are : Wear resistance Corrosion Resistance Vacuum filling and discharge arrangements Special shaft seals Heating & cooling jackets

Ribbon Blender

140,000 - 500,000 Per Piece

01 Piece(s) (MOQ)

MAGWELL Batch type powder blenders are of wide application and highly efficient. They are used in leading processing plants for mixing materials such as chemicals, foods, drugs, medicines, cosmetics, plastics, synthetics, dyes, fertilizers, insecticides, animal feeds, and many other products. Horizontal, single shaft with double proportioned ribbon is housed in the tubular mixing drum. The vortex ribbon rotates with main shaft and thus bring raw material move towards direction of vortex ribbon. We can design round or rectangular shape inlet port on top cover, discharge valve (manual, pneumatic or electric driven) in middle of bottom. MAGWELL Ribbon Blender which is ideal for light to medium mixing. Working Principle: Internal and exterior ribbon move the raw material in different direction when main shaft speed driven by drive unit at a nominal speed. The exterior ribbon transfers the material from the ends to the center while the inner ribbon moves the material from the center to the ends. This counter-current action results in highly homogenous Blending due to strong and three-dimensional movements in the whole process. Features: It is of wide range applications in different fields. It applies to various materials and particle sizes with high homogeneity The vessel fabrication is stable, robust and easy to install and maintain. The whole Blending process is reliable which results in low maintenance and low wear It is suitable to add less than 15% liquid additive by spray nozzles while the Blending homogeneity is high For viscous or cohesive materials, it performs much better than other horizontal Blender The minimal gap between ribbon and vessel ensures Blending efficiency and minimal dead spots Vacuum or air inflation is also applicable to some special purposes As per different raw materials or special purposes, ribbons can be changed into blades or ribbon. High speed choppers are also optional It is highly efficient within short time. For different raw material and particle sizes, the homogeneity is very high Jacket like dimpled jacket, electric heating bars jacket, water jacket, heat transfer oil jacket, steam jacket is widely used in different applications The performance of packing seal and air purge seal for the main shaft seal is good. Meanwhile, packing gland made of PTFE which is of abrasion resistance, waterproof and long service life It is easy to clean through cleanout door or top lid Discharges including flap valve, slide gate valve, ball valve and butterfly valve are optional for different solutions. Moreover, different control like manual, pneumatic, electric drives are available Applications : The ribbon mixer is generally used in the mixing of viscous or adhesive powder material, or the mixing of powder which needs to add liquid, and paste material. Meanwhile, because it is difficult to clean viscous material, the machine is suitable for the mixing case, where the output is large and there is no need of displacing material variety frequently. Mixing of dry or wet materials & pastes food ingredients (meal, sugar, …) chemicals (fertilizer, dertergent, …) minerals (plaster, pigment, refractory, powder, …) vegetal stuff All the controls are mounted on the front panel and are clearly designed. An attractive plastic cabinet with carrying cum tilt bracket makes the instrument light in weight and portable. LED display gives direct reading with 1gauss resolution on the 2k range and 10 gauss resolution on the 20 K range. The unit is supplied with a calibrated transverse Hall Probe.

Ribbon Blender

Get Price Quote

1 Piece (MOQ)

The Ribbon Blender is a versatile and efficient mixing equipment used across various industries for blending dry powders, granules, and other materials. Its unique ribbon design ensures thorough mixing and homogeneity in the blend. With its robust construction and customizable features, this blender offers reliable performance and consistent results.Description A Ribbon Blender consists of a U-shaped horizontal trough and a set of inner and outer helical ribbons mounted on a central shaft. The rotation of the shaft causes the ribbons to move material both radially and axially, ensuring thorough mixing. The gentle mixing action prevents product degradation and ensures uniformity in the blend. The blender is equipped with a discharge valve for easy removal of the blended material.Where to use Pharmaceuticals: Blending of active pharmaceutical ingredients (APIs), excipients, granules, and powders.Chemicals: Mixing of various chemical powders, pigments, additives, and intermediates.Food Processing: Used for blending food ingredients such as powders, spices, flavorings, and nutritional supplements.Plastics: Blending of plastic resins, additives, colorants, and compounds in the plastics industry.

ribbon blender machine

75,000 Per piece

1 piece (MOQ)

Ribbon Blender

150,000 - 380,000 Per piece

1 piece (MOQ)

The RIBBON BLENDER is ribbon mixer machine widely used for the manufacture of dry powder, talcum powder, granules, spice and low-viscosity paste and liquid in chemicals, pharmaceuticals, food and cosmetics industries. It’s especially suitable for mixing solids with solids and solids with liquids, Approximate two third of the volume of the container of Ribbon Blender/mixer is filled to ensure proper mixing. Ribbon Blender mixer is Suitable for Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive, Chemical and Cosmetic products handling large Dry and wet powder volume. It consists of a horizontal “U” Vessel with horizontally installed shaft. Hexacon Enterprises make Horizontal Ribbon Blenders is an high efficient and versatile blending machines for mixing of dry powder, granule and viscous paste homogeneously. Ribbon blender mixer to given perfect r mixing due to the innovative designs of spiral agitators inside of its U-shape Cone chamber. Ribbon blender with Screw conveyor , ribbon blender with bin , ribbon blender with sifter , ribbon blender with product transfer input and output , liquid spray systems, working plat form with variable speed drive or PLC base operation we offer as per customer product and process , Horizontal ribbon mixers range from 50-25000L or more capacity as per requested by customer . Ribbon blender and mixer with stainless steel construction or Mild steel construction main body with stainless steel U shape mixer with bottom product discharge manual and auto valve , control panel , product bin etc we offering as per customer demand for wide industreis Food, Cosmetic, Waterproof Porcelain Glazed Polished Vitrified Tile Strong Adhesive, Floor Adhesive /Ceramic, Chemical, Plastic , Dry Powder, Putty, Modified Corn Starch, Real Stone Paint, Animal feed, Pharmaceutical, Fertilizer, Plastic, Battery etc…… We offer Quality with best mixer machines, mixing machine, blender, powder mixer manufacturers and suppliers by Shree Bhagwati Group of companies. RIBBON Mixers has been developed with advanced technology to achieve high blending capabilities and is among the most efficient machines in the market. The ribbon mixing equipment can be used in either the batch or continuous flow form to achieve an even and homogeneous blend in a wide range of products. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers. Capacity FROM 50 LITERS TO 15000 LITERS The ribbon blender machine comprises of a horizontal U shaped trough and a specially developed a double helical, fabricated ribbon agitator that rotates within the trough. The machine design is based on a proven agitator technology that efficiently achieves triple mixing action and ensures fast and efficient blending. The equipment dimensions and design of the operating parts are well balanced to provide balanced material movement within the container and avoids dead spots while rapidly discharging the product. The ribbon mixer machine is made with user friendly features such as wear resistance, corrosion resistant, vacuum filling and discharge arrangements, special shaft seals, heating and cooling jackets and in a variety of sizes and models for specialized applications. The operating capacity of the ribbon blender mixer ranges from 100 liters up to 8000 liters capacity, and it is constructed with stainless steel for maximum durability.

ribbon blender machine

100,000 Per piece

1 piece (MOQ)

Ribbon Blender

Get Price Quote

Leveraging on our industrial knowledge, we have established ourselves as a leading Manufacturer, Exporter & Supplier in the industry. We offer Ribbon Blender Machine to our esteemed customers at attractive price. It boasts striking features such as light weight, strong built and lasting life. Our excellent distribution system enables you to get it delivered to your doorstep in no time. Additional Information : Ribbon blenders are large, specialized blenders meant for mixing materials in bulk. A ribbon blender is a large trough-shaped machine with curved metal strips shaped like ribbons. This is what Ribbon Blender means. Ribbon Blenders consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer helical agitators. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 300 fpm moves materials both radically and laterally to ensure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 100% of the rated capacity of the blender. The ingredients are put in the trough and the various metal ribbons mix them until they are fully incorporated with one another. Specifications Machine Name - Ribbon Blender Machine weight - 150 kgs. Machine size - 3 feet X 2 feet X 5 feet height. Machine Model - AERB50 Machine capacity - 100 KG. Vessel capacity - 165 Liters. Motor Power; 1 HP 440VAC, 3 Phase. Gear Box - 1 - 60 ratio, worm geared. Blade rotation speed - 20 RPM. Vessel size - 400mm Width X 400mm Depth X 500mm Length. Power consumption - 1 HP Single Phase, 220 VAC 50 Hz. Bottom discharge shutter provided. Forward reverse switch attached. All product contact parts are in Stainless steel 304 quality only.

blender mixer machine

300,000 - 1,000,000 Per Piece

1 Piece (MOQ)

We are associated with ACE Industry Mumbai for supply of various types of Blender as per process requirements. Pharmachem Engineering will take care for service and spare at your doorstep.

Mild Steel Ribbon Blender

Get Price Quote

1 piece (MOQ)

A ribbon blender mixer is a type of industrial mixing equipment used to blend powders, granules, and other bulk materials. It's known for its efficiency in achieving a uniform mix in a short period. Here's a breakdown of how it works and its key features: How It Works: Design: The blender consists of a horizontal, cylindrical shell with a ribbon-like agitator mounted inside. The ribbon agitator has two helical ribbons that rotate in opposite directions. Mixing Action: As the ribbons rotate, they move materials from the center to the outer edges and back again, creating a continuous flow that ensures thorough mixing. This action helps achieve a homogenous mixture with minimal segregation.

U Shaped Ribbon Blender

45,000 Per Piece

1 Piece (MOQ)

Ribbon Blender Mixer machine

250,000 Per Piece

1 Piece (MOQ)