Roofing nail making machine

Get Price Quote

Roofing Sheet Making Machine

1,500,000 Per Piece

1 piece (MOQ)

Best Deals from Roofing Machine

Roofing Sheet Roll Forming Machine

Get Price Quote

Used Roofing Sheet Making Machine

900,000 Per Piece

1 Piece (MOQ)

Roofing Sheet Making Machine

125,000 Per piece

1 piece (MOQ)

Steel Roofing Sheet Making Machine

3,200,000 Per Piece

2 Piece(s) (MOQ)

Roofing Sheet Making Machine

Get Price Quote

PANEL ROLL FORMER

Get Price Quote

• Low-cost, High-quality • Double Layer Roof Panel Roll Forming Machine • Wall roll forming machine • Roof panel machine Profile • Feeding width:1000mm • Effective width:840mm • Material thickness: 0.4-0.8mm Process flow • Decoiling • feeding • forming • cutting • production Manual Decoiler • Material coil inner diameter: 450mm-700mm • Max coil width: 1000mm • Carrying capacity: 5T Forming Device • Number of forming steps: 18 steps • Shaft material: 45 steel with harden treatment, outer diameter 85mm • Roller material: 45steel • Main motor power: 15kw • Forming speed: 8-10m/min • Voltage: 220V/50Hz/3 phrase Cutting Device • hydraulic cutter • blade, puncher and mold material: Cr12 steel with quenched treated 60-62C • cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor. Controlling Device • screen: 5.7 inch Delta screen from Taiwan • PLC: Delta DVP14ES from Taiwan • coder: Delta Hydraulic • Advanced hydraulic system from Taiwan • Power: 11kw Simple output frame • simple frame weld bu 8 U bar, 1 pcs of 3m Packing • Container packing of the line suitable for overseas shipping • The subject can be loaded in one 40’ GP container. • Packing style: Naked and covered by plastic film, spare parts and some small parts packed in wooden box. Assemble, train the machine • It is free to assemble and train the machine, but the buyer must pay for the round-trip airplane ticket, and arrange accommodation during that time Maintain: It is free to maintain the machine the first year after you buying, include changing the main components. The first year hence, you will pay for our technician $50/day to maintain the machine. And its component is not free, if you need to get it from us. (The buyer should supply airplane ticket and accommodation, if he need maintain). Component and Function: • Sheet guiding equipment: Using guiding equipment of leader sliding block style. The width and the left or right position can be adjusted only by adjusting the leader, then the sliding block can realize left or right movement. • Mainframe Transmission: Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet. • Roll forming system: The main frame of machine is welded separately and the outside wall is connected by screw after being roto-blasted on the surface. The rollers are surface-chrome plated after being machined by the exact machine tool.

Automatic Roofing Sheet Making Machine

1,500,000 Per Piece

1 Piece (MOQ)

Roofing Sheet Making Machine

Get Price Quote

Sprinter Roof Seaming Machine

Get Price Quote

Automatic Roof Sheet Forming Machine

Get Price Quote

automatic roof sheet making machine

Get Price Quote

we manufacture automatic roof sheet making machine,roll forming machine, metal sheet cold roll forming machine which is a process to shape different types of sheets or metals. the machine makes different shapes of metal sheets. we apply the latest computer technology and incorporate it with sophisticated hydraulic systems to enhance the automatic machinery that rolls out rolls that are best in the market. the machine is durable, efficient and precision engineered.

Metal Roof Sheet Making Machine

1,000,000 Per Piece

Roof Sheet Forming Machine

Get Price Quote

We are offering roof sheet forming machine. Ppgl roofing sheets roofing sheets color coated roofing sheets aluminum roofing sheet colored roofing sheets ppgi roofing sheets industrial roofing sheets corrugated metal curved roofing sheets corrugated roofing sheets coated roofing sheets corrugated asphalt roofing sheets plant interior roofing sheets roofing metal sheets roofing sheets corrugated color coated roofing sheet color coded roofing sheets frp roofing sheet roofing sheet coil roofing sheet roofing sheets coil metal roofing sheetppgl roofing sheets roofing sheets color coated roofing sheets aluminum roofing sheet colored roofing sheets ppgi roofing sheets industrial roofing sheets corrugated metal curved roofing sheets corrugated roofing sheets coated roofing sheets corrugated asphalt roofing sheets plant interior roofing sheets roofing metal sheets roofing sheets corrugated color coated roofing sheet color coded roofing sheets frp roofing sheet roofing sheet coil roofing sheet roofing sheets coil metal roofing sheetppgl roofing sheets roofing sheets color coated roofing sheets aluminum roofing sheet colored roofing sheets ppgi roofing sheets industrial roofing sheets corrugated metal curved roofing sheets corrugated roofing sheets coated roofing sheets corrugated asphalt roofing sheets plant interior roofing sheets roofing metal sheets roofing sheets corrugated color coated roofing sheet color coded roofing sheets frp roofing sheet roofing sheet coil roofing sheet roofing sheets coil metal roofing sheet

Roofing Sheet Making Machine

1,100,000 Per Piece

MECHANIZED ROOF BOLTING MACHINE

200,000 - 1,000,000 Per Piece

1 piece (MOQ)

Radiant Hydraulic Roof Bolter is a rotary roof bolting machine with dust suppression system suitable for drilling vertical holes of 27mm to 43mm diameter & anchoring of roof bolts in underground mines in strata hardness upto 750 kg/cm2. It is a totally indegenous equipment with modular construction consisting of 3 main assemblies- drive unit, telescopic leg & control arm. It can run with tapping from any underground hydraulic machinery like SDL, LHD, Road Headers or preferably by an independent powerpack. The machine has all operational controls on the handle of the pivoting arm itself which can be pushed down near the leg where it is automatically locked facilitating easy transportation. During operation it allows total control as well as safety to the driller.

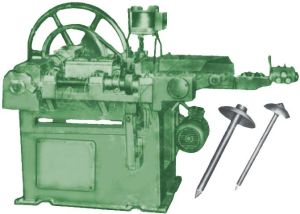

Roofing nail making machine

1,150,000 - 1,151,000 Per piece

1 piece (MOQ)

Roofing nail making machine

Get Price Quote

The plant consists of the main machine, washer cutting press, polishing barrel and nail cutter and die grinding machine, Suitable for Plain type and Twisted Type Roofing Nails, Twisted Roofing Nails require an Optional Wire Twisting Machine to make Twisted Wire which is then fed to the Roofing Nail Machine to make Twisted Stem Nails. Plain Washers made on the press are fed in the hopper of the main machine. On every stroke, one washer is inserted, given shape and fixed into the nail,Ready Nails are then polished in the Polishing Barrel.

Galvanized Coil Cutting Machine For Roofing Sheet

Get Price Quote

The major concern of our organization is to provide only quality approved products to the customers and thus we check each product at all stages. A famed name, the company is enlisted amidst the well-known Suppliers of Galvanized Coil Cutting Machine For Roofing Sheet. Features : Steel body Sharp blades used Easy to install Safe in functionality Low noise Jerk free functionality Ref : CTL P52-02Other Details : Port of Dispatch - Mumbai, India Production Capacity - 15 Delivery Time - 8 to 12 weeks Packaging Details - This machine consist of several equipment. 40 ft.