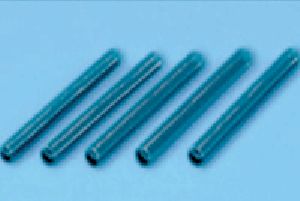

Splice Protection Sleeves

Get Price Quote

The Splice Protection Sleeves are designed to completely encapsulate splice and offer environmental and mechanical integrity of coating or buffer of optical fibre after splicing. Splice Protection Sleeves are manufactured using very advanced and precisely controlled manufacturing technology. Features Outer tube conforms to MIL-I 23053 / 5 class 2 Inner tube made from Polyolefin Copolymer (Ethyl Vinyl Acetate) Resistant to heat shocks Effectively encapsulate fusion splices Better corrosion resistance even in coastal environment Sleeves are pre-shrunk which ensures integrity of assembly during transportation Available in different types, diameters and lengths as per customer requirement. Standard Sleeve Available in 60 mm & 45 mm lengths Diameter after shrinking is 3 mm Available in clear & colored versions Slim Sleeve Reduced dia components for a smaller finish Available in 60 mm, 45 mm & 40 mm lengths Diameter after shrinking 2.5 mm Dielectric Sleeve Non metallic central strength member Resistance to corrosion & electricity Available in 60 mm & 45 mm lengths Diameter after shrinking 3 mm / 2.5 mm Micro Sleeve Used where space is very limited Available in 35 mm & 25 mm lengths Recovered dia 1.5 mm Ribbon Sleeve Suitable for 4 to 12 fibre Ribbon High mechanical strength with ceramic strength member Standard length 40 mm Applications Protection of single fibre splices Protection of Ribbon fibre splices Specifications Outer Tube Polyolefin Working Temperature: -50°Cto 125°C Min. Shrink Temperature: 90°C Ultimate Strength: 220 Kg / cm² Elongation: 650% Specific Gravity: 0.95 Fungus Resistance: Inert Solvent & Acid Resistance: Good Toxicity: None Ends: Smooth, even & consistent Strength Member (Single Fiber Sleeves): 316 Stainless steel with rounded and polished ends Strength Member (Ribbon / Dielectric sleeves): Polished ceramic (white) or Quartz (transparent)