Zero Drilling Machine

Get Price Quote

Radial Drilling Machine

Get Price Quote

we offer Radial Drilling Machine We are manufacturer and Exporter of Radial Drilling Machine . Offered machines can be installed easily and work smoothly. These radial drill machines undergo various tests before delivering the clients in order to ensure their high performance and long service life. Our vendors use the most advanced technology and the finest quality components in the fabrication of these machines. Descriptions of Radial Drilling Machine Special CAM operated head clamping Quill balancing Auto-feed enabled by electromagnetic chuck Hardened gears for both speed and feed gear box Drilling Capacity In Steel 63mm,; Drilling Capacity In Cast 75mm;Boring Capacity In Steel 100mm; Min. Max. distance between spindle & column 350 1600 Radial Arm Swivel 0-360 Degrees; Number of spindle feeds 6 Range of Spindle feeds 0.09 to 1.20 mmrev Range of Spindle speeds 36 to 1796 rpm. Accessories of Radial Drilling Machine Drill Holder Brackets, Twist Drills: High speed steel with straight and tapered shanks drills ( high helix drill, core drill, oil hole drill, straight-fluted drill, deep hole or gun drill, spade drill, and Step drill, and saw-type hole cutter; Single point boring tool; Center drills regular and bell type; Reamers: rose, carbidetipped, shell, adjustable and expansion-type reamers; Machine Taps: Gun, Stub flute and spiral flute each type supplied in sets of three; fluteless tap; countersinks; All to be supplied with the respective accessories such as drill jig chucks, guide plate and spacers. Functions for: machining holes and cutting internal thread.

Best Deals from Drilling Equipment

cork boring machine

Get Price Quote

For drilling uniform and straight holes in cork or rubber stoppers. Cast-iron frame with wood platform 10 cm. diameter to support work and adjustable guide row central hole through wheel spindle for ejector rod and introduction of lubricant (eater of methylated Spirit). Complete with set of 12 nickel-plated borers cutting sizes from 7 to 25 mm.

Core Drilling W/O cutter Electronic

Get Price Quote

Core Drilling W/O cutter Electronic : These drilling machines are extremely robust, heavy duty, compact and reliable. The sliding group is rectified so as to assure a very soft and accurate drilling movement. The drilling excursion is 550 mm and the machine can drill cores up to 200 mm dia. Built in water swivel to cool the diamond bit. The robust steel base is equipped with wheels for easy site displacements, together with four levelling and stabilizing feet. All working and moving parts are cadmium plated for rust protection. The machine is supplied complete “except”: diamond bit, expander coupling and spanner which have to be ordered separately. A) Core Drilling W/O cutter electric 100 x 200 (B) Core Drilling W/O cutter electric 150 x 300 (C) Core Drilling W/O Petrol Engine 100 x 200 (D) Core Drilling W/O Petrol Engine 150 x 300 (E) Core Drilling W/O Diesel Engine 150 x 300 5 H.P. (F) Core Drilling W/O Diesel Engine 150 x 300 7 H.P.

Pillar Drill Machine

15,000 - 17,000 Per piece

1 Piece (MOQ)

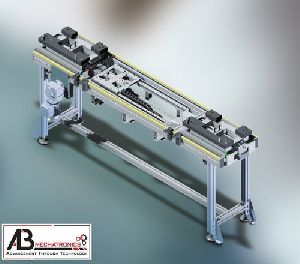

Special Purpose Machine

100,000 Per Piece

cork boring machine

Get Price Quote

For boring straight and uniform holes in cork or rubber stoppers. Cast iron frame with platform to support stopper, 4 holes for fixing to bench top. Complete with a set of 12 nickel plated steel borers, cutting sizes from 7 mm to 25 mm.

Cutting Core Drilling Machine

Get Price Quote

Core Drilling Machine

Get Price Quote

NAUGRALABS LABORATORY PRODUCT NAME: CORE DRILLING MACHINE FOR TESTING LAB NaugraLabs Laboratory Product Code: NLE-Export-113005 Description and Specification for Lab Tenders Core Drilling Machine. Technical Description » Heavy duty, Pillar type frame with 2 HP, single phase, AC motor. » Varying Cutting feeds provided with water-fed swivel head which can be connected to suitable water supply. Provision at base for water collection/drainage. » Core Preparation from regular and irregular samples Core Size : EX to NX » Clamping arrangement to hold specimens with regular/irregular shapes to the base of machine. » Four cutting speeds of 600, 800, 1100 and 1500 rpm. Following Core Bits are available as options: Core Drilling Bit, 21.46 mm dia (EX size) Core Drilling Bit, 30.10 mm dia (AX size) Core Drilling Bit, 38 mm dia Core Drilling Bit, 42.04 mm dia (BX size) Core Drilling Bit, 54.74 mm dia (NX size) mechanical lab equipments manufacturers

Heavy Percussion Rigs

Get Price Quote

This drilling is used most frequently in the mineral exploration industry. (This tool is also known as a Down-the-hole drill.) The drill uses a pneumatic reciprocating piston-driven "hammer" to energetically drive a heavy drill bit into the rock. The drill bit is hollow, solid steel and has ~20 mm thick tungsten rods protruding from the steel matrix as "buttons". The tungsten buttons are the cutting face of the bit. The cuttings are blown up the outside of the rods and collected at surface. Air or a combination of air and foam lift the cuttings. RAB drilling is used primarily for mineral exploration, water bore drilling and blast-hole drilling in mines, as well as for other applications such as engineering, etc. RAB produces lower quality samples because the cuttings are blown up the outside of the rods and can be contaminated from contact with other rocks. RAB drilling at extreme depth, if it encounters water, may rapidly clog the outside of the hole with debris, precluding removal of drill cuttings from the hole. This can be counteracted, however, with the use of "stabilizers" also known as "reamers", which are large cylindrical pieces of steel attached to the drill string, and made to perfectly fit the size of the hole being drilled. These have sets of rollers on the side, usually with tungsten buttons, that constantly break down cuttings being pushed upwards. The use of high-powered air compressors, which push 900-1150 cfm of air at 300-350 psi down the hole also ensures drilling of a deeper hole up to ~1250 m due to higher air pressure which pushes all rock cuttings and any water to the surface. This, of course, is all dependent on the density and weight of the rock being drilled, and on how worn the drill bit is.

Cork Press

Get Price Quote

Cast iron, for softening corks evenly, by rolling without increasing the porosity. To accommodate corks up to 32mm dia., on wooden base. Cork press wheel type.

Sand Boring Machine

600 Per Piece

20 Piece (MOQ)

Drilling Rig

Get Price Quote

We are one of the prominent manufacturers and suppliers of a qualitative range of Drilling Rigs. These are specially manufactured using premium quality components to ensure sturdiness and long functional life. We strictly follow international industrial standards to manufacture these Rigs. One can avail these Rigs in different standard and customized specifications. We are engaged in manufacture of reverse Rotary Drilling Rigs, Direct Rotary Drilling Rigs and Percussion Rigs. Reverse Rotary Rigs are suitable for drilling up to 600 meters Below Ground Level in alluvial soils.

Core Drilling Machine (Motorised)

Get Price Quote

1 Piece(s) (MOQ)

Product description:suitable to cut drill cores of concrete, rocks, stones, tiles or the similar material. The machine is suitable for core samples of size upto 150mm diameter with the help of thin walled diamond bits which are at extra cost. The machine has sturdy base with pillar support in which rack & pinion is provided for adjustment in height and penetration assembly. The levelling screws are provided at the base. For gripping the sample in position suitable grips are provided. A suitable electric motor, standard make is fitted in the machine with cooling arrangement with water. The base frame is also fitted with wheels for ease of transportation. Salient features ã�â¢ã¯â¿â½ã�⢠dimension approx. Are as under : height : 1300mm base : 600 x 1200mm head travel on rack : 350mm drill speeds : 900 rpm for soft samples and 350rpm for hard samples. Water swivel : built in the machines. Suitable for 230 volts ac, single phase accessories : 1. Thin wall diamond bits 2. Core barrel.

cork boring machine

Get Price Quote

For drilling uniform and straight holes in cork or rubber stoppers. Cast-iron frame with wood platform 10 cm diameter to support work and adjustable guide rod, central hole through wheel spindle for ejector rod and introduction of lubricant(water or methylated spirit). Complete with set of 12 nickel-plated borers cutting sizes from 7 to 25 mm.

cork boring machine

Get Price Quote

For drilling uniform and straight holes in cork or rubber stoppers. 'C' type Cast-iron frame with rugged and stable base having a platform of about 1 Oem diameter at its top to support work. Includes adjustable guide rod, and a central hole through wheel spindle for ejector rod and introduction of lubricant (water or methylated spirit). Complete with set of 12 nickel-plated borers with cutting sizes from 7 to 25mm diameter.

Drilling tool

Get Price Quote

We are offering drilling tool this is a armed wheel type strain gauge drill tool dynamometer designed to measure thrust and torque during drilling operation. This dynamometer is suitable for drilling a hole up to 25mm size in mild steel. With this dynamometer students can study the change in these force by varying speed, cut and feed features: 1. rigid in construction & sensitive transuding and amplifying system for accuracy in force measurement. 2. compact two channel digital force indicator. 3. use of cutting fluid during operation is possible scope of supply: 1. mechanical sensing unit and work piece holder with strain gauges. 2. control panel housing digital force indicator to measure both forces simultaneously, balancing potentiometer, connoting cables. 3. necessary switches, fuses and screen printed front plate. 4. the dynamometer is calibrated at factory with help of proving ring and readings are directly in the from of kg.

CNC PCB Router Drilling Machine

280,000 Per Piece

Pavement Core Drilling Machine

Get Price Quote

The Pavement Core Drilling Machine is petrol engine powered. RoadBuilding drill has been designed specifically for the purpose of drilling test cores from or holes in, Roads, Airport Runways, Bridges etc. The Machine comprises of two vertical support columns, which carry the Drill headEngine assembly with the help of screwed spindle.

Core Drilling Machine

Get Price Quote