Plate Type Heat Exchanger

Get Price Quote

1 Piece(s) (MOQ)

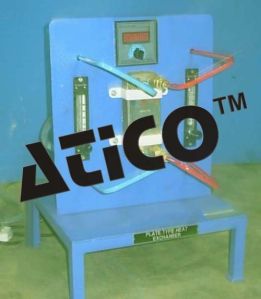

Product description:plate type heat exchanger consists of frame in which independent metal plates are clamped between a head and follower. The plates are sealed at their outer edges and around the ports by gaskets, which are so arranged that the liquid and the heatingcooling media are directed alternately into passages formed between the plates. The hot fluid enters at the top on the right side of the fixed end cover and flows downwards through alternate channels between the plates. The hot fluid leaves the exchanger through a connection at the bottom of the fixed end cover. The cold fluid enters at the bottom of the left side of the fixed end cover. The cold fluid flows in counter current flow through alternate channels between the plates and leaves the exchanger at the top on the left side of the fixed end cover.

Plate Type Heat Exchanger

Get Price Quote

We are offering plate type heat exchanger. range of experiments 1. Determination of lmtd of heat exchanger. 2. Determination of heat transfer rate, heat transfer co-efficient and effectiveness of plate type heat exchanger

Looking for Plate Heat Exchanger Services Providers

Plate Type Heat Exchanger

Get Price Quote

The plate heat exchanger is made up of profiled plates with water flowing through the spaces between them. The plates are soldered in such a way that two separate flow channels are formed. These are one “cold” and one “hot” flow channel, in an alternating arrangement. Hot and cold water flow continuously. Part of the thermal energy of the hot water is transferred to the cold water. Valves are used to adjust the flow of hot and cold water. The supply hose can be reconnected using quick release Couplings allowing the flow direction to be reversed. This allows parallel flow and counter flow operation. During experiments, temperature curves are plotted and displayed graphically. Additionally, the measured values can be recorded and processed using data acquisition software. The mean heat transfer coefficient is then calculated as a characteristic variable. The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments