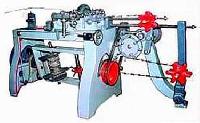

Barbed Wire Making Machine

Get Price Quote

Features : simple, sturdy & robust in designeasy to operatecapable of making barbed wire of two ply and four barbsindigenous productionassembled with multiple gears and loversaccurately timedperforms the multiple function of feeding, barbing, twisting, cutting & coilingworks without the aid of manual labor technical specifications : capable of making g.i. Wires of 3 types :main ply two lines of 12g with 4 barbs made 12g wire at distance of about 3” or 75mm apart.main ply two lines of 12g with 4 barbes made of 14g wire at distance of about 3” or 75mm apart.main ply two lines of 14g with 4 barbes made of 14g wire at distance of about 3” or 75mm apart.production : 500 to 600 kgs per shift of 8 hours.electric motor : 5 hp. X 960 rpmspace required : 15 ft. X 12 ft.weight : 1000 kgs approx.acessories : 4 nos. Wire stands. Installation : it is easy and simple to install the machine. The machine’s stands should be securely bolted to the foundation and the machine should be accurately aligned and leveled.

Automatic Barbed Wire Making Machine

170,000 Per Piece

Best Deals from Barbed Wire Making Machine

Barbed Wire Making Machine

Get Price Quote

Tensile Stregth: H.B. Fully Hot Dipped Galvanized wire with under 30 kg. F/MM to 55 kg. F/MM capacity/production: 6 Qtl/8 HR shift exclusive maintenence for 12/12swg. Wire keeping 140 to 220 barbs min with length to coil maximum 400 meters & weigth per bundle 40/50 kg. (bundle size 16" x 10") Width Barb Spacing: 3 to 4" pitch also adjustable with additional gears in winding unit which ever could be supplied only under special demand. Our Major emphasis are laid down upon its adjustibility of parts easy maintenance operator has wasy approach in setting all arms, cutters making the machine parts fool-proof it ensures easier dismantling, assembling, loading, unloading as well consequent view over flow of formed wire, all the adjustable parts are all together accessible and machine is supplied along with a set of spare twisting sleeve, Take up real, pay off stands, it requires 5 H.P. slow speed 3 H.P. 50C/S squirral eage induction motor with reversible starter whichever is not supplied with the machine it is designed in its heavy structure using closed grain castiron & steel in EN-36 series, all the gears are processed by bevel genrator & hobbing machines 15 Qtl enclusive of Pay-off stands.

3 HP Barbed Wire Making Machine

130,000 Per Piece

1 Piece (MOQ)

ALLIED BRAND BARBED WIRE MAKING MACHINE

Get Price Quote

We are offering allied brand barbed wire making machine. Adjustibility of parts easy maintenance operator has wasy approach in setting all arms, cutters making the machine parts fool-proof it ensures easier dismantling, assembling, loading, unloading as well consequent view over flow of formed wire.

Barbed Wire Making Machine

Get Price Quote

1 Set(s) (MOQ)

1. Main ply two lines of 12G with 4 barbs made 12G wire at a distance of about 3� or 75mm apart. 2. Main ply two lines of 12G with 4 barbs made 14G wire at a distance of about 3� or 75mm apart. 3. Main ply two lines of 14G with 4 barbs made 14G wire at a distance of about 3� or 75mm apart.

Barbed Wire Making Machine

175,000 Per Piece

1 Piece (MOQ)

Capable of making G.I. Wires of 3 types. Main ply two lines of 12G With 4 barbs made 12G wire at distance of about 3” or 75mm apart. Main ply two lines of 12G with 4 barbes made of 14G wire at distance of about 3” or 75mm apart. Main ply two lines of 14G with 4 barbes made of 14G wire at distance of about 3” or 75mm apart Installation : The installation of the machine is quite simple and easy as that of any other machine,care being taken that the stands of the machine is securely bolted to the foundation and machine is properly aligned and leveled accurately.

Barbed Wire Making Machine

Get Price Quote

Our major emphasis are upon its adjustability of parts and easy maintenance. Operator has an easy approach in setting all arms, cutters by making the machine parts fool proof. It ensures easier dismantling, assembling, loading unloading as well as consequent view over flow of formed wire. The machine is designed in its heavy structure using grain cast iron and steel in EN-36. All the gears are processed by bevel generator and hobbing. The machine is 1200 kg in weight exclusive of pay - off stands. Range of Production: 12x12, 12x14, 14x14 SWG :ongitudinal for Barbs: 12/14 SWG Pitch of the Barb: variable from 2" to 6" Floor Space: 8"x5" Power Required: 5 H.P. Machine R.P.M. 200 Production Capacity: 500 to 600 Kg. Appx. (Per Shift)

barbed wire machinery

Get Price Quote

barbed wire machinery, bolt making machines, Screw Making Machines

barbed wire machines

Get Price Quote

barbed wire machines, Roll Forming Machines, bolt making machines

Barbed Wire Making Machine

Get Price Quote

Barbed Wire Making Machine, Automatic Head Trimming Machines