Vacuum Gas Flush Can Seaming Machine

Vacuum – Gas Flush Can Seaming Machine Semi-Automatic Vacuum – Gas Flush Can Seamer. Vacuum Seaming for Nuts, Milk Powder, etc. Can also be used as a pressure Seamer for Tennis Ball Cans.

...more

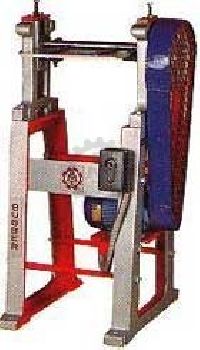

side seam locking machine

Used for Folding and Locking the Side Seam of Round or Irregular shaped cans. Semi-Automatic, Foot Pedal Operation. Power Press type Double Operation. 1 for Folding and 1 for Locking. Tools made from special Die Steels, hardened and ground for absolute precision. Heavy-Duty Construction.

...more

Semi Automatic Round Can Seamers

Semi Automatic Round Can Seamers Semi-Automatic Round Can Seaming Machines for Metal, Composite and PET Cans. Semi-Automatic Round Drum Seaming Machines

...more

Semi Automatic Filter Seaming Machine

Semi Automatic Filter Seaming Machine Filter Seamer for Spin-On and CAV Filters. Oil, Fuel and Air Filter Seaming

...more

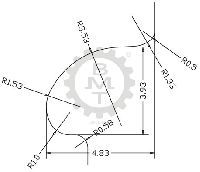

Seamer Tooling Seaming Rollers

BMT manufactures seamer tooling (seaming rollers and chucks) for a wide range of machines, besides our own. These can be made from samples or from drawings.

...more

Round Can Seaming Machines Semi Automatic

SRS:200:PN ROUND CAN SEAMER(Pneumatic Lifting System) Semi-Automatic Round Can Seaming machine. Dual Push Button or Foot Switch operation with Pneumatic Lifting system. Can be fitted with an optional Automatic End/Lid Feeder. Available with Stainless Steel Tooling, Covers, Contact Parts and Cladding. Heavy Duty Construction with all moving parts CNC Machined. 4 Roller Seaming ensures consistent and leak proof Seaming. Ability to seam a wide range of Can Diameters with a quick changeover of tooling. For Height changes only a simple setting is required (no change parts). PLC or Timer based Control Panel (depending on order configuration). With Foot Switch: The Can with the Lid (End) to be seamed is placed on the lifter plate. A Foot Switch (electronic) is pressed and the seaming operation begins. After completion, the lifter plate with the seamed Can are automatically brought down to the rest position. With Dual Push Buttons: The Can with the Lid (End) to be seamed is placed on the lifter plate. The dual push buttons are simultaneously pressed and released. The Can is lifted to the Seaming Chuck and the seaming operation begins. After completion, the lifter plate with the seamed Can are automatically brought down to the rest position.

...more

Round Can Flanger

Simultaneously Flanges both ends of Round Cans. Semi-Automatic press type operation through key-clutch-cam. Consistent and even flanging ensures proper seaming. Heavy-Duty body made from close-grain cast iron. CNC Machined, Hardened and Ground flanging dies for high accuracy and consistency.

...more

Round Can Beading Machine

Used for Beading Grooving Corrugating Round Tin Cans. Semi-Automatic press type operation through key-clutch-cam. Increases Rigidity and Stackability of Cans. High Bead accuracy and consistency CNC Machined Beading Rollers for high accuracy. Heavy Duty Construction

...more

Non-Round Irregular Can Seaming Machine

SPS:200 NON ROUND (IRREGULAR) CAN SEAMER Irregular Can Seamer for Non-Round shaped cans like square, rectangular, oval, etc. Also Used for Seaming Capacitors and other similar applications. Available with Stainless Steel Tooling, Covers, Contact Parts and Cladding. Heavy Duty Machine Construction. Seaming Chucks, Cams and Seam Rollers are CNC machined for precision. Semi-Automatic. Foot-pedal or Foot Switch (Pneumatic Lift) operation. Can remains stationary during seaming. 4 roller Can seaming ensures consistent and leak-proof seaming. Ability to accept a wide range of Can Sizes and Heights with a quick changeover. The Can with the Lid (End) to be Seamed is placed on the lifter plate and the pedal or button are pressed (optional). The Can is lifted to the Seaming Chuck and the seaming operation begins. After completion, the lifter plate with the seamed Can are automatically brought down to the rest position. The machine can be fitted with a Control Panel with Push Buttons and a Pneumatic Lifting system doing away with the mechanical foot pedal.

...more

Muffler Silencer Seaming Machine

Muffler – Silencer Seaming Machine Seamer for Automotive and 2 Wheeler Silencer End Cap Curling and Hemming Machines. Tie-Rod Curling and Sealing Machines

...more

Irregular Can Seamers

Irregular Can Seamers Non-Round Can Seaming Machine for Square, Rectangular, Oval, Triangular Cans. Irregular Can Seamer for 15 Kg 15 ltr. Large Size Cans

...more

Inward J Filter Seaming machine

Inward ‘J’ Filter Seaming machine Filter Seamer for Inward Seaming of Hydraulic and Industrial High Pressure Filters.

...more

Fully Automatic Round Can Seamers

Fully Automatic Round Can Seamers Fully Automatic Round Can Seaming Machines for Metal, Composite and Plastic Cans. Automatic Capacitor Seaming Machines.

...more

Fully Automatic Filter Seaming Machine

Fully Automatic Filter Seaming Machine Fully Automatic Spin-On Filter Seamer for Oil, Hydraulic, Fuel and Air Filters. CAV Filter Seaming.

...more

Semi-Automatic Filter Seaming Machines

SRS:320:FTR and SRS:320:PN FILTER SEAMER Filter Seamer for Seaming spin-on oil filters for automobile, industrial and hydraulic applications. 4 roller seaming head ensures leak proof seaming. Seaming arms and levers profile cut from steel plate to ensure rigidity. Heavy-duty construction for lifetime trouble-free performance. All moving parts are CNC machined for precision. Improved Seaming Head Design for Seaming Filters with Sheet Thickness’ up to 1.50m*. Available in semi-automatic foot pedal, foot switch or dual push button operation. Can use pre-curled or straight cover assemblies. Quick changeover of seamer tooling. Easy to Operate, Maintain and Service. SRS:320:FTR Model: The FIlter with the Cover Assembly to be seamed is placed on the lifter plate and the pedal is fully pressed and released. The Filter is lifted to the Seaming Chuck and the seaming operation begins. After completion, the lifter plate with the seamed Filter are automatically brought down to the rest position. SRS:320:FTR:PN Model: The FIlter with the Cover Assembly to be seamed is placed on the lifter plate. A Foot Switch or Dual push buttons are pressed and released. The Filter is lifted to the Seaming Chuck and the seaming operation begins. After completion, the lifter plate with the seamed Can are automatically brought down to the rest position.

...more

Capacitor Grooving Machines

Capacitor Seaming and Capacitor Grooving Machines Capacitor Seamer for Round, Rectangular, Square and Oval Capacitors Capacitor GroovingBeading Machine.

...more

Can Seaming Machine

With an experience of over 50 years, BMT has established a wide customer portfolio across industries such as Can Making, Canning (Food, Beverage, Paint, Chemical, Lubricants, etc.), Capacitors, Automotive & Industrial Filters, Car and Motorcycle Mufflers & Silencers, Composite Can Makers and scores of Special Applications.Semi-Automatic Round Can Seaming Machines for Metal, Composite and PET Cans.

...more

Can Reforming Machine

Used for Re-Forming Flattened Round Cans. Reforming is done between One Rubber and One Metal Roller. Reformed Can is without visible marks. Heavy-Duty Construction.

...more

Bubber Drum Seaming Machine

Brand Name : Bubber

Body Rolling Machine

Suitable for rolling Tin Sheet into round form. Heavy-Duty Construction. Semi-automatic foot pedal operation. Rollers are Hardened, Ground & fitted with Needle Bearings. Supplied complete with Electric Motor, Starter, V-belt & Guards.

...more

circular body rolling machine

Fully Automatic Can Seaming Machine

Drum Seaming Machine

Be first to Rate

Rate This