Wire Stitching Machine

1 Piece (MOQ)

Window Type Lamination Machine

1 Piece (MOQ)

Vertical Type Paper Corrugation Machine

450,000 - 950,000 Per NOS

1 NOS (MOQ)

Thermal Lamination Machine

1 Piece (MOQ)

Sheet Pasting Machine

1 Piece (MOQ)

sheet lamination machine

300,000 - 650,000 Per Piece

Semi Automatic Folder Gluer Machine

400,000 - 1,000,000 Per Piece

1 Piece (MOQ)

semi automatic flute laminator machine

400,000 - 1,000,000 Per piece

1 Piece (MOQ)

Semi Automatic Die Cutting and Creasing Machine

4,500,000 - 7,500,000 Per piece

1 Piece (MOQ)

Semi—Automatic Die—Cutting and Creasing Machine is professional for cutting offset print box, combining the advantages of domestic and foreign products. There is high strength gripper,advanced open gripper structure can adapt to a variety of signal paper, corrugated board; Front, back and side gauge assure the cutting accuracy It also has intermittent mechanism with high precision, sensitive pneumatic clutch, pneumatic lock plate , PLC, HMI. Working speed, paper account, total running time are very clear on the screen; Input and output monitor make it easy to exclude the breakdowns. It adopt the frequency converter to the main motor, using for stepless governor. There are many protection sensor to ensure the workers safety. What’ s more, the front and back pressure can be adjusted individually, manual running is very convenient, die—cutting without clipper margin can be realized.

...more

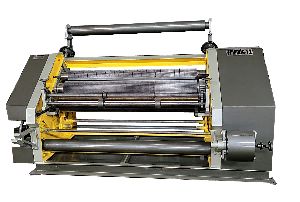

RS4 Rotary Slotting Machine

400,000 - 900,002 Per piece

1 Piece (MOQ)

FRIENDS series rotary slotting machine is a kind of comprehensive equipment that slotting, slitting, cutting corner, creasing. Its main feature is feeding single piece cardboard by hand, common bend card board are also OK. Main Features Used lead edge feeder with vacuum feeding system, fast and smoothly, (or kick feeder option). Motorized (or PLC) adjust side and front baffl e, manual adjust black buffer (motorized). Planet gear type motorized observe and reverse adjustment in 360°. All of shaft precision grind, chrome plated. Electric adjusting box height (or PLC adjust). Slotting crease joint movement by motorize control (PLC option). High quality 48 CrMo slotting knife with induction hardness. Frequency conversion motor drive, save power. Equipped with the photo electricity counter, display production amount

...more

rotary half cutting machine

1 Piece (MOQ)

Rotary Die Cutting Machine

650,000 - 1,200,000 Per piece

1 Piece (MOQ)

Function and Uses The machine adopts chain feeding system and double roller rotary type. It can perform all process of slitting, creasing , corner cutting and hit special whole at one time. It has advantage of high precision, easy to operate, long service life and low cost. Paper Feeding Unit Adopt lead edge feeding system with vacuum adsorption auxiliary feed, (optional equipment kick feeding system) Speed: 10000 Sheets/Hr, die-cutting precision: ±0.75mm. Manual adjust former block board and computer control lateral block board, dial indicator. Leading paper roll have groove glue surface to prevent the crushed card board and increase the accuracy of feeding. Main Characteristics The drum made of high quality steel tube, thickness 30mm, do balance treatment, plated chrome. Full machine gear made of 45# steel have been quenched treatment, Adopts lock-alx key less and cross-head system connect with shafts fi nish no gap adjustment. Driving part uses pull pump to lubricating (motorized phase adjustment type used spray lubricating). Oil box made of thick iron plate to avoid oil leakage. Phase adjustment by manual operate with micro-adjustment (or motorized adjust in 360º) Die Roller (bottom roller) lift-down adopts pneumatic control, manual or automatic operation. Rubber roller (top roller be wrapped anvil cover from “Maxdura” Brand from Taiwan (or CUE, DAY option), long use life. Rubber roller (top roller) can move automatically, move range ±40mm. Rubber roller (top roller) fix overrunning clutch to compensate line speed automatically, and avoid one position cutting. Equipped with anvil cover repair device, prolong use life.

...more

Roll To Roll Lamination Machine

1 Piece (MOQ)

Reel To Sheet Cutting Machine

1 Piece (MOQ)

Programmable Paper Cutting Machine

1 Piece (MOQ)

Features Box type design of parts and high grade material of main parts gives rigidity & long life to the machine Specially designed electromagnetic clutch & brake unit ensures quick action of knife carrier Latest hydraulic power pack unit with double pressure cylinder for smooth hydraulic transmission Infra red photo electric safety device in front of cutting knife AC drive system for smooth and uniform movement of back gauge The back gauge is driven by dual speed motor with separate E.M. clutch brake unit mounted on its lead screw Slot closing belt is provided on main bed of machine Dust free feather touch key board for smooth operation of programmed unit Program controlled air cushion table for easy movement of bulky stock Program execution possible either in semi or fully automatic mode.

Packaging Type : Carton Box

...more

Platen Punch Machine

400,000 - 1,800,000 Per piece

Pizza Box Making Machine

400,000 - 1,200,000 Per SET

Paper Packaging Box Making Machine

400,000 - 2,500,000 Per SET

Oblique Type Paper Corrugation Machine

600,000 - 1,500,000 Per Nos

1 Nos (MOQ)

Oblique High Speed Corrugation Machine

1 Piece (MOQ)

Features Building and operation Bearings are enabled with rollers. delivered with pre-heaters asunder from the three regular heaters tode-moisturize the liner Equipped with binary shaft motorized tone lading roll stand & bull Construction, operation, and bulldozing, The flute breakers are mounted on bearings for smooth operation and extended life. The flute breakers are made of special amalgamation sword & bull The main bearing are waxed with high temperature grease It is enabled by gum Hard chromed rollers for improved performance and machine life Two pre-heaters are provided to de-moisturize the paper. A variable speed motor is recommended for improved quality and frugality in destruction at a lower cost. Capacity to lift up to 1 ton roll This model includes a variable drive motor as standard. Handed with' Goliath' type motorized Hydraulic roll stage.

...more

Non Programmable Paper Cutting Machine

1 Piece (MOQ)

Laminated Sheet Separator Machine

1 Piece (MOQ)

Hydraulic Paper Cutting Machine

1 Piece (MOQ)

Features Box type design of parts and high grade material of main parts gives rigidity & long life to the machine. Specially designed electromagnetic clutch & brake unit ensures quick action of knife carrier Latest hydraulic power pack unit with double pressure cylinder for smooth hydraulic transmission Infra red photo electric safety device in front of cutting knife AC drive system for smooth and uniform movement of back gauge The back gauge is driven by dual speed motor with separate E.M. clutch brake unit mounted on its lead screw Slot closing belt is provided on main bed of Machine

...more

Hot Foil Stamping Machine

1 Piece (MOQ)

Attachment of hot foil unit is available with multiple Foil Rollers options (Single Pull / Double Pull / Triple Pull / Four Pull) Heating Plate Multiple Chambers heating plate having separate compartments with separate circuit on control panel to operate any or all the compartment at the same time. It plays key role in minimising wastage of electricity. Aluminum Plate is affixed on the Heating plate to provide best quality foil Impression. Heating plate is fitted with digitally displaced machine with thermostatically heaters. Re-winder Unit : Re winder units are separate for each foils. Jumpers : Jumpers are designed with advanced technology to minimize wastage of foils.

...moreBe first to Rate

Rate ThisOpening Hours

One of the pioneering names in the printing, packaging and binding machinery manufacturing industry, Friends Engineering Company has been working with the same level of dedication and sincerity since we opened our doors in 1960. Our vision has always been to evolve with the changing times and technology. And this has helped us to increase our customer base in leaps and bounds.

We began with a vision and aim to bring world-class technology to our Indian customers ever since we began when the country was in the initial stages of development after freedom from British rule. Since then, we have been instrumental in bringing about technological development with all our machinery that caters to the printing, binding and packaging industries across the entire country.

At Friends Engineering, we represent world-class technology at its best in all our machinery. With this, we have created a coveted niche for ourselves in the industry. And today, we boast of a huge clientele which has been loyal to us ever since we began business with them.

Our manufacturing facility in Amritsar, Punjab, is equipped with the best machinery, tools and tackles that enable us to call ourselves as the best. We represent the finest quality machines with 100% client satisfaction and contentment, which is the reward that we have been seeking for.