Tool Cutter Grinding Machine

Get Price Quote

Allied brand Grinding Machine is specially designed to sharpen and grinding the dies and cutters of the machine. It is fitted with four grinding wheels of different shapes and special attachments.

Surface Cum Edge Grinding Machine

125,000 Per Piece

Special Features Most suitable for grinding knives and blades of paper cutting machines, plastic cutting machines, metal cutting shears, etc. Electro-Magnetic 360o Swiveling Table for flat, bevel and multi surface grinding. Machines Constructions Machine Bed Wedled, modular construction principle. Smooth inner area for good cooling water drainage & easy cleaning. Guideways Hardened and ground steel bands for main and side guides, easily exchangeable. Electro Magnetic Table Fixed for flat grinding with total table coverage, in Electro-Magnetic Design. Electro-Magnetic swivelling table for flat, bevel and multi surface grinding in one setting up operation, swivelling 360, multiple bearing points with large diameter journals for maximum rigidity additional clamping sides with ‘T’ slots & clamps. Electro Magnetic Table locking, by hand. Grinding Head Carriage Heavy Casting mounting on four reels with eight New-Departure dust proof ball bearings which act as rollers. Four reels guide the carriage in the carriage ways of the bed. The sliding base, mounted on the top of the carriage, is adjustable to feed the grinding segmental or cup-wheel to the knife. The motor base can be swiveled 10 to 25 degrees, so that the knife can be ground either straight or concave as paper knives require only 5 degrees swivel of motor base. Down-Feed for Grinding Tool Multiple spindle system for play and weight equalisation. Automatic Down-Feed also available. Grinding Motors SIEMENS OR NGEF Brand. Grinding Head Cylindrical type bonded to flange for light grinders, segmental heads for heavy grinding machines. For quick re-setting or changing of the segments, an easily accessible changing station is situated at the rear of the machine. To ensure vibration – free running, all grinding wheel flanges and segmental heads are fitted with adjustable balancing weights. For obtaining maximum segment use, patented segment savers can be used. Cooling System Water tank attached with the machine. Cooling fluid application by the electro-coolant pump. Electrical Unit All electrical controls are housed in the master panel board.

Best Deals from Grinding Machine

Automatic Knife Grinding Machine

Get Price Quote

Automatic Surface Grinding Machine

210,000 Per Piece

1 Inch (MOQ)

Hydraulic Surface Grinder Machine

Get Price Quote

Tool Grinding Machine

Get Price Quote

We are one of the highly acknowledged firms engaged in providing Tool Grinding Machine to the customers. We are one of the successful Manufacturers, Exporters and Suppliers of Tool Grinding Machine from Punjab. Tool Grinding Machine is used in many industries for sharpening and grinding of cutters and dies of machines. It is available in different shapes and attachments with four grinding wheels. Best quality of raw material and latest technology is used for the fabrication of Tool Grinding Machine. We sell Tool Grinding Machine at market leading prices. Features : Hassle free performance Excellent functionality Rust proof body Rugged construction Technical Specifications : One H.P. x 2600 R.P.M. Motor is fitted in it. These grinders are Industrial Duty Grinders complete with inbuilt drive suitable for operation on AC 415 Volts Three Phase or 220 / 230 V Single Phase, 50 Cycles Supply. Each grinder is complete with five grinding wheels. One fine & one coarse, two wheel Guards with exhaust outlets, two adjustable tools rests, rotary switch, condenser (only in single phase) in the base and connecting cable or terminal block.

Grinding Machine

Get Price Quote

The company is engaged in bringing forth high quality Grinding Machine. Experienced engineers have designed the Grinding Machine to ensure flawless performance. The Grinding Machine is extensively used for grinding and mixing processes. The Grinding Machine can be availed at a reasonable price. Attributes : Sophisticated designRobust constructionLongevityHassle-free usage

Grinding Machine

Get Price Quote

We are offering Grinding Machine. the nails cutters of wire nails making machines become blunt and require regrinding. a special grinding machine have manufactured for grinding all the profiles of cutters this machine is provided with special type of fixtures, so that even a semi skilled worker can grinding cutting tools easily after a short training.

Grinder Machine with Four Grinding Wheel

35,000 Per Piece

1 Piece (MOQ)

Note : Due to constant improvement, we reserve the right to change / modify any machine.

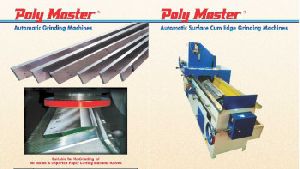

automatic surface cum edge grinding machine

Get Price Quote

ALLIED BRAND GRINDING MACHINE

Get Price Quote

We are offering allied brand grinding machine. Allied brand grinding machine is specially designed to sharpen and grinding the dies and cutters of the machine.

CNC Center Less Grinder Machines

Get Price Quote

CNC Center less Grinder Salient Features: Cantilever filmatic grinding wheel spindle provides wear resistant, hydrodynamic, self-centering support that is consistent under varying grinding load. Very tough and durable twin-support regulating wheel spindle No dular cast iron base for strength, stability and vibration damping. Highly accurate CNC profile contouring on both wheels. In feed resolution to 0.1 micron, CNC control up to 7-axis. Swift and easy set up and wheel changeover.

Tool & Cutter Grinder Machine

Get Price Quote

Tools and cutter grinder machine specification 12”x4” table size distance between center: 300x100 raising block dia: 75mm swing over table block: 279mm table cross traverse: 125mm table dimensions: 550x125 table slot 2 nos: 11mm table swing: 180* head swing: 360* speed of spindle: 2800rpm motor ½ hp 3 phase(ph): 2800rpm standard attachments 1. universal tooth rest. 2. tool sharping vice. 3. universal holder.

Knife Grinding Machine

520,000 - 550,000 Per Piece

Tool & Cutter Grinder

Get Price Quote

We are offering tool and cutter grinder (capable of grinding hob upto 1.d.p.).

Automatic Knife Grinding Machine

Get Price Quote

This machine is necessary equipment for trade of working. It is composed of machine body,grinding head and electromagnetic chuck,etc. Features: Machine Bed : Welded, Modular construction principle Guideways : Hardened and steel bands for main and side guides, easily exchangeable Machine table : Fixed for flat grinding with total table coverage, in Electro - magnetic design or as cast iron table with 'T' slots & clamps. Electro - Magnetic swiveling table for flat, bevel and multistage grinding, in one setting up operation, swiveling 360 degrees, multiple bearing points with large diameter journals for maximum rigidity. Additional clamping sides with 'T' slots & clamps. Swiveling table in cast iron for mechanical clamping. Mechanically table locking by hand.

Instant Grinder Machine

Get Price Quote

Precision Surface Grinder

Get Price Quote

We are the manufacturers and supplier of this products.

automatic surface cum edge grinding machine

Get Price Quote

head surface grinder

Get Price Quote

We are offering wide range of Head Surface Grinder to our valued clients that is ideal for engine re builders. Moreover, our range of machines is capable of grinding and milling of cylinder blocks and is made of cast iron or aluminum alloy. Further, these are available in various specifications, and can also be custom made as per the clients requirements