window lamination machine

Special Features: Chromed bearing drive free guide rollers for wrinkle free jobs. Wrinkle removal break. Two unwinding stations for strip lamination. Film slitting attachment. Adjustable adhesive tray. Film roll movement adjustment upto 70mm. Hard chromed rollers. Ideal for sheel to reel, Reel to reel lamination.

Material : Stainless Steel

Shape : Rectangular

Voltage : 220V

Packaging Type : Carton Box

Pressure : Low Pressure, Medium Pressure, High Pressure

Specialities : Superior Performance, Rust Proof, Durable

...more

Semi Automatic Paper Cutting Machine

Special Features: Hand/Foot Clutch: This unique system is easily operated. Auto Lubrication: Centralised lubrication for all moving parts, through lubrication pump. Auto Alarm: Sounds/Lights as soon as the clutch is operated. Ensures the safety of the operator. Multi-disc Clutch: Most revolutionary type, transmite positive slipless drive with minimum maintenance. Magnifying Lens: Affords a clear reading on the measuring tape.

Brand Name : POLYMASTER

Material : Stainless Steel

Automation Grade : Semi Automatic

Warranty : 1 Year

Country of Origin : India

...more

Rotary Paper Cutting Machine

Special Features: The machines are manufactured with graded casting and steel to ensure accuracy for long time. The machines are strongly built to cut much higher stocks than similar other machines. The height of table is adjustable to avoid and under cutting. Automatic disengagement in the highest position of the knife is there for hand and power drive. The knife holder can be adjusted to compensate the grinding of the knife. The back guage is tunable for slanting and triangular cutting. Narrow strip cutting device has been provided for cutting small labels and visiting cards. Ball bearings and bushes have been provided at vital places. Safety guards are provided at vital places. Fine finish, excellent painting and essential parts have been plated.

Automatic Grade : Manual

Country of Origin : India

Brand Name : Polymaster

...more

Plain Lamination Machine

Special Features: Chromed bearing drive free guide rollers for wrinkle free jobs. Wrinkle removal break. Two unwinding stations for strip lamination. Film slitting attachment. Adjustable adhesive tray. Film roll movement adjustment upto 70mm. Hard chromed rollers. Ideal for sheel to reel, Reel to reel lamination.

Material : Stainless Steel

Shape : Rectangular

Packaging Type : Carton Box

Pressure : Low Pressure, Medium Pressure

Overall Weight : 100-200kg

Usage : Industrial

Specialities : Superior Performance, Rust Proof, Durable

...more

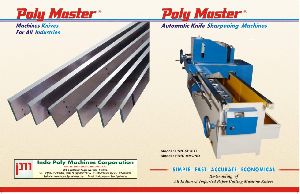

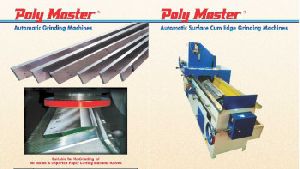

Automatic Knife Grinding Machine

Special Features: Most suitable for grinding knives & blades of paper cutting machines, plastic cutting machines, metal cutting shears, etc. Swiveling Table (Clamping Type) to grind the job at various angles (0o to 90o) Machines Constructions Machine Bed Wedled, modular construction principle. Smooth inner area for good cooling water drainage & easy cleaning. Guideways Hardened and ground steel bands for main and side guides, easilyexchangeable. Machine Table(Clamping Type) Cast Iron table with ‘T’ slots & clamps. Cast Iron swiveling table for bevel grinding in one setting up operation, swiveling 360, multiple bearing points with large diameter journals for maximum rigidity additional clamping sides with ‘T’ slots & clamps. Machine Table(Clamping Type) Cast Iron table with ‘T’ slots & clamps. Cast Iron swiveling table for bevel grinding in one setting up operation, swiveling 360, multiple bearing points with large diameter journals for maximum rigidity additional clamping sides with ‘T’ slots & clamps.Mechanically table locking Grinding Head Carriage Heavy Casting mounting on four reels with eight New-Departure dust proof ball bearings which act as rollers. Four reels guide the carriage in the carriage ways of the bed. The sliding base, mounted on the top of the carriage, is adjustable to feed the grinding segmental or cup-wheel to the knife. The motor base can be swiveled 10 to 25 degrees, so that the knife can be ground either straight or concave as paper knives require only 5 degrees swivel of motor base. Down-Feed for Grinding Tool Multiple spindle system for play and weight equalisation. Automatic Down-Feed also available. Grinding Motors SIEMENS OR NGEF Brand. Grinding Head Cylindrical type bonded to flange for light grinders, segmental heads for heavy grinding machines. For quick re-setting or changing of the segments, an easily accessible changing station is situated at the rear of the machine. To ensure vibration – free running, all grinding wheel flanges and segmental heads are fitted with adjustable balancing weights. For obtaining maximum segment use, patented segment savers can be used. Cooling System Water tank attached with the machine. Cooling fluid application by the electro-coolant pump. Electrical Unit All electrical controls are housed in the master panel board

Weight : 2500-10000kg

Color : WHITE/BLUE/YELLOW

Voltage : 380V, 440V

Automatic Grade : Automatic

Driven Type : Electric

Country of Origin : India

...more

Paper Cutting Knives

Decisive Advantages: High-alloyed steels Highest cutting efficiency Greatest durability Lowest regrinding cost Special Features: ‘Poly-Master’ Machine knives has been manufactured over a period of 20 years of experience. The difference inherent in knives is simply due to the way they have been machined and finished. A knife is not merely a piece of steel showing up a cutting edge. It is essential to find out what lies concealed behind this outer appearance which cannot be proved, until the knives-fitted into any appropriate machine-begin to do their work. But this “intrinsical value” is determining by the machining performance each individual knife had to undergo.

Size : Depend on Size

Material : Iron, Metal

Thickness : Depend on the Model

Certification : ISO 9001: 2015

Length : 120-240mm, 240-480mm, 480-960mm, Depend on the Machine Model

Application : Paper Cutting

Color : Metallic

Condition : New

Surface Finishing : Finished

Country of Origin : India

...more

Die Cutting and Creasing Machine

1 Piece(s) (MOQ)

RNN series Automatic Die Cutting And Creasing Machine is a special equipment applying to die-cutting of advanced colored boxes made of paper. The machine combines several advantages over many other die-cutters both at home and abroad.

Brand Name : Indo Poly Machines Corporation

Material : Stainless Steel

Certification : ISO 9001: 2015

Voltage : 380V

Condition : New

Finishing : Coated

Machine Weight : 3 Ton 15 Ton

Automatic Grade : Automatic

Packaging Type : Carton Box, Wooden Box

Power Source : Electric

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

Speciality : High Precision Cutting

Corrosion Resistance : No

Usage : Printing & Packaging Unit

Die Cut Size Max : 15mm

...more

automatic surface cum edge grinding machine

Special Features: Most suitable for grinding knives and blades of paper cutting machines, plastic cutting machines, metal cutting shears, etc. Electro-Magnetic 360o Swiveling Table for flat, bevel and multi surface grinding. Machines Constructions Machine Bed Wedled, modular construction principle. Smooth inner area for good cooling water drainage & easy cleaning. Guideways Hardened and ground steel bands for main and side guides, easily exchangeable. Electro Magnetic Table Fixed for flat grinding with total table coverage, in Electro-Magnetic Design. Electro-Magnetic swivelling table for flat, bevel and multi surface grinding in one setting up operation, swivelling 360, multiple bearing points with large diameter journals for maximum rigidity additional clamping sides with ‘T’ slots & clamps. Electro Magnetic Table locking, by hand. Grinding Head Carriage Heavy Casting mounting on four reels with eight New-Departure dust proof ball bearings which act as rollers. Four reels guide the carriage in the carriage ways of the bed. The sliding base, mounted on the top of the carriage, is adjustable to feed the grinding segmental or cup-wheel to the knife. The motor base can be swiveled 10 to 25 degrees, so that the knife can be ground either straight or concave as paper knives require only 5 degrees swivel of motor base. Down-Feed for Grinding Tool Multiple spindle system for play and weight equalisation. Automatic Down-Feed also available. Grinding Motors SIEMENS OR NGEF Brand. Grinding Head Cylindrical type bonded to flange for light grinders, segmental heads for heavy grinding machines. For quick re-setting or changing of the segments, an easily accessible changing station is situated at the rear of the machine. To ensure vibration – free running, all grinding wheel flanges and segmental heads are fitted with adjustable balancing weights. For obtaining maximum segment use, patented segment savers can be used. Cooling System Water tank attached with the machine. Cooling fluid application by the electro-coolant pump. Electrical Unit All electrical controls are housed in the master panel board.

Brand Name : POLYMASTER

Material : Mild Steel

Color : WHITE/YELLOW/BLUE PAINTED

Voltage : 380V

Driven Type : Electric

Country of Origin : India

Usage : Automotive Industry

...more

Industrial Machine

Opening Hours

Indo Poly Machines Corporation was established in the year 1975 in Amritsar, Punjab. We are the leading manufacturer, exporter and supplier of die-cutting and creasing machine, knife sharpening machine, surface cum edge grinding machine and much more. Our professional factory is engaged in the production of a complete set of amazing machines and equipment. Our factory has a large number of technicians and professionals mechanics who have been engaged in machine research and development, production and manufacture, marketing and after-sales services for many years. The factory has complete products and diversified varieties and professionally produces and deals in different types of machines.

The factory has become one of the manufacturing enterprises with the most complete products series and the best quality and after-sales service in the domestic industry. We provide in setting up machines which meet the requirements of our customers and clients. We have developed advanced machinery and brings new ideas for improvement.

Why Choose Us?

For many years our factory has always been focusing on high technology, centring on talented personnel, taking the scientific research and development as a priority, pursuing the ultimate goal of satisfying higher and further target. We work hard with great concentration and serve diligently. We strive to produce excellent machined for our customers and clients.