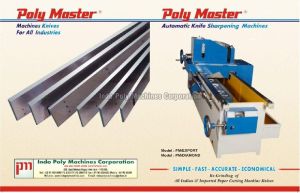

Surface Cum Edge Grinding Machine

125,000 Per Piece

Special Features Most suitable for grinding knives and blades of paper cutting machines, plastic cutting machines, metal cutting shears, etc. Electro-Magnetic 360o Swiveling Table for flat, bevel and multi surface grinding. Machines Constructions Machine Bed Wedled, modular construction principle. Smooth inner area for good cooling water drainage & easy cleaning. Guideways Hardened and ground steel bands for main and side guides, easily exchangeable. Electro Magnetic Table Fixed for flat grinding with total table coverage, in Electro-Magnetic Design. Electro-Magnetic swivelling table for flat, bevel and multi surface grinding in one setting up operation, swivelling 360, multiple bearing points with large diameter journals for maximum rigidity additional clamping sides with ‘T’ slots & clamps. Electro Magnetic Table locking, by hand. Grinding Head Carriage Heavy Casting mounting on four reels with eight New-Departure dust proof ball bearings which act as rollers. Four reels guide the carriage in the carriage ways of the bed. The sliding base, mounted on the top of the carriage, is adjustable to feed the grinding segmental or cup-wheel to the knife. The motor base can be swiveled 10 to 25 degrees, so that the knife can be ground either straight or concave as paper knives require only 5 degrees swivel of motor base. Down-Feed for Grinding Tool Multiple spindle system for play and weight equalisation. Automatic Down-Feed also available. Grinding Motors SIEMENS OR NGEF Brand. Grinding Head Cylindrical type bonded to flange for light grinders, segmental heads for heavy grinding machines. For quick re-setting or changing of the segments, an easily accessible changing station is situated at the rear of the machine. To ensure vibration – free running, all grinding wheel flanges and segmental heads are fitted with adjustable balancing weights. For obtaining maximum segment use, patented segment savers can be used. Cooling System Water tank attached with the machine. Cooling fluid application by the electro-coolant pump. Electrical Unit All electrical controls are housed in the master panel board.

Usage : Automotive Industry

Material : Stainless Steel

...more

Knife Grinding Machine

450,000 Per Piece

Special Features Most suitable for grinding knives & blades of paper cutting machines, plastic cutting machines, metal cutting shears, etc. Swiveling Table (Clamping Type) to grind the job at various angles (0o to 90o) Machines Constructions Machine Bed Wedled, modular construction principle. Smooth inner area for good cooling water drainage & easy cleaning. Guideways Hardened and ground steel bands for main and side guides, easilyexchangeable. Machine Table(Clamping Type) Cast Iron table with ‘T’ slots & clamps. Cast Iron swiveling table for bevel grinding in one setting up operation, swiveling 360, multiple bearing points with large diameter journals for maximum rigidity additional clamping sides with ‘T’ slots & clamps. Machine Table(Clamping Type) Cast Iron table with ‘T’ slots & clamps. Cast Iron swiveling table for bevel grinding in one setting up operation, swiveling 360, multiple bearing points with large diameter journals for maximum rigidity additional clamping sides with ‘T’ slots & clamps.Mechanically table locking Grinding Head Carriage Heavy Casting mounting on four reels with eight New-Departure dust proof ball bearings which act as rollers. Four reels guide the carriage in the carriage ways of the bed. The sliding base, mounted on the top of the carriage, is adjustable to feed the grinding segmental or cup-wheel to the knife. The motor base can be swiveled 10 to 25 degrees, so that the knife can be ground either straight or concave as paper knives require only 5 degrees swivel of motor base. Down-Feed for Grinding Tool Multiple spindle system for play and weight equalisation. Automatic Down-Feed also available. Grinding Motors SIEMENS OR NGEF Brand. Grinding Head Cylindrical type bonded to flange for light grinders, segmental heads for heavy grinding machines. For quick re-setting or changing of the segments, an easily accessible changing station is situated at the rear of the machine. To ensure vibration – free running, all grinding wheel flanges and segmental heads are fitted with adjustable balancing weights. For obtaining maximum segment use, patented segment savers can be used. Cooling System Water tank attached with the machine. Cooling fluid application by the electro-coolant pump. Electrical Unit All electrical controls are housed in the master panel board

Application : Sharpening

Weight : 100-200kg

Voltage : 220V

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

...more

Knife Grinding Machine

Opening Hours

Indo Poly Machine is a stalwart in the Indian engineering sector. We are counted as a manufacturer-supplier of knife sharpening machines and surface cum edge grinding machine. Precisely engineered using robust ideas and modern technology, our poly machinery is known for its aesthetic design and long lasting performance. The design of machinery is crafted using modern technology that allows bringing maximum output for the user. The teams always acquire the raw material from certified vendors in the market. For further queries, you can dial our numbers.

Indo Poly Machine is operating for over 3 decades in Amritsar (Punjab). Since 1975, we’ve accustomed with multiple trends that benefitted us. Owing to the consistency in work, our name is etched amid the leading names in the market.

Infrastructure

Ours is a modern manufacturing unit. It is equipped with machinery and instruments that help in the maximum production of knife sharpening machines and surface cum edge grinding machine.

Clientele

Being a promising name serving the engineering industry, we’ve been victorious in establishing a huge clientele Amritsar and pan India. We aspire for expanding our client base internationally.

Why Us?

We have different teams working for us. Right from R&D Bureau and distributors, our framework is organized for offering smooth services to everyone across Punjab. We consider the quality of our finalized products before supplying them ahead.