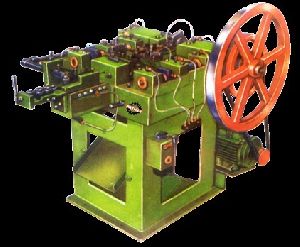

Nail Making Machine

1,500,000 Per Piece

Wire Nail Making Machine

Get Price Quote

We are well reckoned as one of the prominent Nail Making Machine Manufacturers based in India. CONSTRUCTION : The main frame of Wire Nail Making Machine is of high grade and all leavers and their components subject to heavy duty are all manufactured from high quality steel and designed with high safely factor. MAIN DRIVE : Operating mechanism of Automatic Nail Making Machine is to longer mount on one common shaft but on two auxiliary shifts thus eliminating long cutter leavers. The cutter slides move in substantial guides and driven directly by cracks acentric. This avoids all detrimental impacts of the cutter against each other consequently reduces cutter wear. CRANK SHAFT : The crankshaft is carried in four bearings, the smooth ruining of the nail machine is thus ensured. FEEDING MECHANISM : Operated by crank drive, which reduces feeding speed. A screw controls the length of intake. The intake cutter is raised mechanically during backstroke so that its wear is considerably reduced. EJECTOR : One ejector fitted with the punch ensures that the nails are ejected at the right moment, avoiding any bending of nails. PRESSURE : The necessary pressure on grip of the dies is obtained shaft the roller. There are seven models of wire nail making machines to cut different length of nail with different gauge of wire.

Best Deals from Nails Making Machine

Roofing nail making machine

Get Price Quote

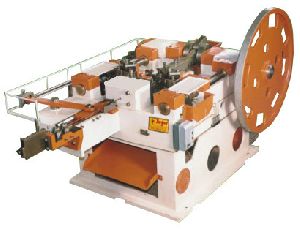

Automatic Wire Nail Machine

Get Price Quote

We are a well-known name as Automatic Wire Nail Making Machine Manufacturer, Exporter and Supplier in Punjab (India). The SMT Automatic high-speed Wire Nail Machines are made from high-grade castings and steel. Our Automatic Wire Nail Making Machines are simple and sturdy in design for friendly use. With advanced features, the Wire Nail Machines are known for their long lasting service. Automatic Wire Nail Making Machines can produce nails from H.B. brass, copper and aluminium wires. All the movements except the pressure for gripping and the ejection, are through cranks, which are essential for smooth running at high speeds maintaining full rate production of well finished nails. Special attention has been given to maintain easy approach to all the required adjustments and settings. Our Automatic Wire Nail Making Machines are available at very reasonable prices.

Automatic Nail Making Machine

100,000 Per Units

Wire Nail Making Machine

Get Price Quote

1 Set(s) (MOQ)

Being a foremost organization in this industry, we are actively engaged in offering the finest quality range of nail machine. Features: sturdy design reliable functioning durable finish standards

Wire Nail Making Machine

200,000 Per Piece

Wire Nail Making Machine

155,000 Per Piece

1 Piece (MOQ)

Perfect Automatic Wire Nails Making Machines are simple and sturdy in design are made from high grade casting & steel. These machines can produce flat head nails, pop nails, round head nails, lost head nails, counter shank head nails, from H.B, copper, aluminium & brass Wires. Drive: Its main crank is directly driven by motor and side-shafts are driven by four bevel gears to ensure correct and permanent adjustment of the cutting tool. The length and thickness of the nails is adjustable. All tools are easily accessible and can be quickly changed. its main and side shafts are fitted with browns bushes to ensure long life. All comes, gears, rollers, roller pins are made from high-quality steel properly heat-treated and grounded for long lasting. Working Of the Machine : The wire end from coil passes throughtening rollers and fed intermittently in the gripping dies, which close firmly allowing heading punch to press the head of the nails, then grip loosened and required length of the nail is fed constantly, where it is cut by cutting tools leaving ample stock for the head of the next nail. Thus ready nail is ejected by the ejector. The operations are repeated in each revolution. Note: Due to constant improvement, we reserve the right to change / modify any machine. (S.W.G.)Production (per minute)PNM-1.51/2" X 1.5" (12 to 38 mm)18-14400-450PNM-21/2" X 2" (12 to 50 mm)16-12300-350PNM-33/4" X 3" (20 to 75 mm)14-9225-275PNM-41" X 4" (25 to 100 mm)12-8175-210PNM-51.5" X 5" (35 to 125 mm)10-6110-125PNM-62" X 6" (50 to 150 mm)8-4100-125PNM-82" X 8" (50 to 200 mm)8-290-100

Automatic High Speed Wire Nails Making Machine Model SE-3

Get Price Quote

This machine is manufactured for the production of wire nails of length from 0.5 inches to 3 inches. It produces upto 300 nails per min.

Nails Making Machine

315,000 Per Piece

Nail Making Machine

100,000 Per Piece

Nail Making Machine

95,000 Per Piece

U Nail Making Machine

Get Price Quote

We are offering U Nail Making Machine.

Wire Nail Making Machine

Get Price Quote

Backed by a state-of-the-art infrastructure, we are involved in manufacturing, exporting and supplying precisely engineered Wire Nail Making Machine. Proffered assemblage is manufactured in accordance with the predefined industry standards. Owing to the excellent performance, rugged construction and consistent operation, offered series is vastly asked for.

Roofing Nail Making Machines

Get Price Quote

Wire Nail Making Machine

Get Price Quote

We offer high speed Wire Nail Making Machine that is appreciated for flawless performance, easy operation and sturdy construction. Our Wire Nail Making Machine is fully automatic wire feeding unit that carries out clamping of wire through conical rollers, heading operation, point forming and process of finished nails automatically. The technical specifications of our Wire Nail Making Machine vary with chosen model of the machine for wire diameter, length of nail and production. Solid main bed bushes increase the bearing surface and eliminate deformation with fluent lubricating oil film that ensures long life of bushes. The flywheel is mounted on a support independent from the main crank-shaft which therefore is not affected by stresses produced by freewheel itself and by the drive belts. Spiral type bevel gears run in continuous lubricating system and need no maintenance and are noiseless. The round section hammer slide allows correct alignment with the connecting rod, a larger support surface and excellent lubrication. Moreover, an air circulation system cools the slide's running guide and keeps dirt away from the slide itself. The nails ejector is driven by a cam, so there is no contact between the punch and the ejector. The crank shaft and lateral shafts are of high quality steel fully ground and are counter-balanced to extend cutters life. Cutters and grippers are adjusted by means of vertically positioned screws operating on the wedges. The grippers die box is made up of two slides; the stationary gripper is mounted on the former, the sliding one is mounted on the latter that offers large bearing surfaces. Grippers can be removed from the box without taking the box off from the press. This allows shortening the down-times. The wire feeding driven by rollswedge system is self-locking. The clamping pressure on the wire is adjustable, the wire release is pneumatic and the centralized lubrication is partially continuous & partially timer controlled. The oil gets accumulated in a tank located in the machine bed and it is filtered both on suction & in delivery machine and is totally covered which exceptionally reduces the noise level. Wire Nail Making Machine is equipped with 110 v auxiliary controls, a PLC (program logic control) controls the lubrication systems, the wrong wire feeding alarm and operator machine safety devices.

wire nail machinery

Get Price Quote

wire nail machinery, bolt making machines, Screw Making Machines

Wire Nail Making Machine

Get Price Quote

Wire Nail Making Machine, Hand Press paper plate machine

Wire Nail Making Machine

Get Price Quote

Wire Nail Making Machine, Rotary Milling Table, two way tilt vice

Wire Nail Making Machine

Get Price Quote

Wire Nail Making Machine, Cold Heading Machine