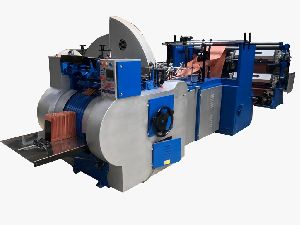

Food Paper Bag Making Machine

590,000 - 960,000 Per Set

1 Set (MOQ)

Paper Bag Making Machine

Get Price Quote

Best Deals from Paper Making Machine

Paper Bag Making Machine

Get Price Quote

Hydraulic Paper Plate Making Machine

104,000 - 105,000 Per Piece

Paper Bag Making Machine

Get Price Quote

Paper Bag Making Machine is Designed to Manufacture Flat and Satchel Paper Bags from Kraft Paper, Greaseproof, White Paper and Poster Paper Etc. in Different Size for Packing Confectionery, Food Stuff, Ready-made Garments, Tobacco, Tea Powder Grocery, Dry Cleaners Etc. Aper Bag Making Machine is Made of Rigid and Robust Construction to Avoid Vibration. all Paper are Arranged in Most Accessible Way Thus Making Operation and Adjustment Very Simple and Quick So that Even An Unskilled Labour Can Easily Operate the Machine Successfully. the Change of Size is Very Easy and Can Be Done in Few Minutes Time. the Machine is Supplied with One Size Plate and One Size Gears to Manufacture One Size of Paper Bag. Different Size Plates & Size Gear for Flat and Stachel Bags are Available At Extra Cost. Mill Reels upto 34 Dia and 34 Width Can Be Accommodated of the Machine. the Width of the Paper Reel to Be Fed On the Machine Can Be Calculated as Under. Flat Bags Twice the Bag Width Plus 2 Cm for Centre Seam. Satchel Bags Twice the Bags Width Plus 4 Time Depth of the Gusset Plus 2 Cm for Centre Seam. Bag Formation : The Required Size of the Bag Us Obtained By Fixing the Exact Size Plate for Flat or Satchel to the Size Plate Holder and the Length to the Tube is Obtained By Changing the Size Gear Wheel, Each Tooth of Which , Represents One Centimeter in Length, the Tube After Being Cut By the Beater Into Exact Size as per the Size Gear is Carried Forward By Means of Conveyor Rollers to the Delivery Cylinder the Delivery Cylinder as the Bottom Fold is Made is the Bag It is Pasted and the Bag is Carried By the Folding Cylinder to the Delivery Table Where It is Released and Delivered in a Vertical Stack. Printing Attachment : Our Two or Four Colour Flexo Printer Can Be Coupled with the Paper Bag Making Machine.

Paper Bag Making Machine

400,000 Per Piece

Paper Pins Making Machine

Get Price Quote

We manufacture a wide range of Paper Pins Making Machine which uses all kinds of precise and durable punching mold to ensure low breakdown rate. Besides, it matches high technology electronic control for not easy to run off. Our machines uses high quality, high efficient spare parts to match all kinds of control and monitor systems. This will enable the machine to automatic stop if there is any problem happened in the process of operation. Also, it will warn with alarm to avoid wasting raw material and protect the machine. Size of product : 3/4" to 1 1/4"wire size : 19 - 23 swg production per minute : 200/250 pcs. (approx)production in 8 hours : 15 kgs (approx)electric motor : 1 h.p (1440 r.p.m)

Automatic 3 And 5 Ply Paper Corrugated Board Making Plant

Get Price Quote

This production line is suitable for large quantity automatized manufacturing and it can produce good quality corrugated cardboard which can meet nationalize standard completely. Higher productivity, better paper board quality, adoption of central control system, simple and easy operation, convenient to repair and maintenance, reliable and safe, greatly lower degree of manpower requirement. This production line adopts the most updated source-saving mode which get heat from the high-temperature guiding oil compared with the steam heating it reduce the source by 60% so that cut the cost effectively. It is economical ideal product and suitable for big and medium carton manufacture.

High Speed Single Paper Corrugating Making Machine

Get Price Quote

Excellent productivity, longer service life and non-corrosive body are the specialties of our Single Paper Corrugating Machine. We are a respectable Manufacturer, Exporter and Supplier of High Speed Single Paper Corrugating Machine from Punjab, India. It is robust, it is efficient, it is pocket-friendly, and whatnot. All these years, we have been successfully delivering even the bulk orders of the machine within the promised time frame. All the credit goes to our logistic network! High Speed Single Face Paper Corrugated Machine:High Speed Single Face Paper Corrugated Board Making Machine. This High speed Single facer offer's a high rate of production and enhanced efficiency. The rollers are mounted on roller bearing for smooth running and longer life, minutely finished flute roll results in perfect formation of flutes. High speed production and the making of quality board across a wide range of paper grades demand precise temperature & moisture control. The integral segments are provided SFO 50 for thermic fluid or steam heating system. Maximum speed depending on paper is 50 meter per min.

Paper Corrugated Board & Box Making Machines

Get Price Quote

Paper Corrugated Board & Box Making Machines in several models and sizes to meet the requirement of related Industry. Corrugation machines are available with normal speed to high speed models and with various fluting options i.e. A, B, C, E & F flutes to meet the requirement both corrugated boxes as well as printed cartons. We also supply the allied machines to make 3, 5, 7, 9 etc. ply corrugated boards & different machines to make complete corrugated box.

Paper Bag Making Machine

Get Price Quote

Modern Paper Bag Making Machines for manufacture of Flat and Satchel Paper Bags from kraft paper, vegetable parchment, poster, glassine and other papers of similar nature. These automatic paper bag making machines have been designed incorporating latest improvements and are available for manufacture of different ranges of paper bags for packing of foodstuffs, confectionery, readymade garments, tobacco and snuff, ice cream and many other items. These paper bag making machines are of excellent construction, all parts arranged in a most accessible way, making operation and adjustments simple and easy. These automatic paper bag machines work on the beater principle i.e. the tubed web is separated into the required tube length by a rotary beater against a serrated plate. These paper bag making machines are also supplied with flexographic printing (aniline printing) attachment for the production of the printed bags in huge quantities. Smooth fabric-roll unwind system Automatic unwind breaking management system Automatic film positioning management system Touch-screen computer interface Heavy duty motor for station movement Ultrasonic welding technology Automatic temperature controls Availability in two shapes ( L & I ) Model: SEN-600B & SEN-600C

semi automatic paper cutting machine corrugated box making machines

Get Price Quote

Courtesy years of experience, our company has emerged as leading suppliers of semi automatic paper cutting machine corrugated box making machines. We offer secured online and offline payment processing methods. The transaction, done through online mode, is instantly forwarded to the payment system. We also accept bank account transfers, cash payments, etc.

CNC Paper Bag Making Machinery

Get Price Quote

Paper bag making machine is made of rigid and robust construction to avoid vibration. All paper are arranged in most accessible way thus making operation and adjustment very simple and quick so that even an unskilled labor can easily operate the machine successfully. The change of size is very easy and can be done in few minutes time. The machine is supplied with one size plate and one size gears to manufacture one size of paper bag. Different size plates & size gear for flat and stachel bags are available at extra cost. Mill reels upto 34” dia and 34” width can be accommodated of the machine. The width of the paper reel to be fed on the machine can be calculated as under. Flat bags twice the bag width plus 2 cm for centre seam. satchel bags twice the bags width plus 4 time depth of the gusset plus 2 cm for centre seam. Bag formation: the required size of the bag us obtained by fixing the exact size plate for flat or satchel to the size plate holder and the length to the tube is obta

Paper Bag Making Machine

Get Price Quote

Paper Bags can be used in hotels, laundries, cloth, garments, saris, gold, diamonds, silver, watch, pearls show rooms, temples, super markets, shopping malls, book / fancy/ gift shops, pharmacy shops and in pharma industries to pack pharma especially to carry dry items.

Paper Bag Making Machine

Get Price Quote

aper Bag Making Machine is designed to manufacture flat and satchel paper Bags from Kraft paper, Greaseproof, White paper and poster paper etc. in different size for packing confectionery, Food stuff, Ready-made Garments, Tobacco, Tea Powder Grocery, Dry Cleaners etc. Paper Bag Making Machine is Made of rigid and Robust Construction to Avoid Vibration. All Paper are Arranged in Most Accessible Way Thus Making Operation and Adjustment Very Simple and Quick So That Even an Unskilled Labour Can Easily Operate the Machine Successfully. The Change of Size is Very Easy And Can be Done in Few Minutes Time. The Machine is Supplied with One Size Plate and One size Gears to Manufacture One Size of Paper Bag. Different Size Plates & Size Gear For Flat And Stachel Bags Are Available At Extra Cost. Mill Reels Upto 34” Dia and 34” Width Can be Accommodated of the Machine. The Width of the Paper Reel to be Fed on the Machine Can be Calculated as Under.Flat Bags Twice the Bag Width Plus 2 CM for Centre Seam. Satchel Bags Twice the Bags Width Plus 4 Time Depth of the Gusset Plus 2 CM For Centre Seam.Bag Formation: The Required Size of the Bag us Obtained by Fixing The Exact Size Plate For Flat or Satchel to the Size Plate Holder And the Length to the Tube Is Obtained by Changing the Size Gear Wheel, Each Tooth of Which , Represents One Centimeter in Length, The Tube After Being Cut by the Beater Into Exact Size As Per the Size Gear is Carried Forward By Means Of Conveyor Rollers to the Delivery Cylinder the Delivery Cylinder As the Bottom Fold Is Made is the Bag it is Pasted and the Bag is Carried by the Folding Cylinder to the Delivery Table Where it is Released and Delivered in a Vertical Stack. Printing Attachment: Our Two or Four Colour Flexo Printer Can Be Coupled With the Paper Bag Making Machine.

Paper Corrugated Board & Box Making Machines

Get Price Quote

We offer a wide range of corrugated board & box making machines. We provide these machines in several models and sizes to meet the requirement of related Industry. Corrugation machines are available with normal speed to high speed models and with various fluting options i.e. A, B, C, E & F flutes to meet the requirement both corrugated boxes as well as printed cartons. We also supply the allied machines to make 3, 5, 7, 9 etc. ply corrugated boards & different machines to make complete corrugated box. Oblique type high speed model offers high rate of production. The machine is fitted with Gear Box which runs in oil bath. The machine has motorised self loading reel stand, 3heaters & 1 pre heating cylinder.

Automatic Paper Plate Making Machines

Get Price Quote

This is a fully automatic paper plate machine which involves no labour. We have to put the roll on the machine, and then Machine takes the paper itself and gives the finished product automatically. You can change the mould according to your requirement. We can use any type of paper (laminated or no laminated),it should be in a roll form Special Features Fully Geared Least Consumption of Electricity Double die 0% Maintenance Fully Automatic Paper Plate Machine (4"inch-14"Inch)without blower

Dual Flute High Speed Paper Corrugation Board Making Machine

Get Price Quote

This Machine offers high rate of production and enhanced efficiency. The rolls are mounted on roller bearing for smooth running and longer life, minutely finished Flute Rolls result in perfect formation of Flutes, Lubrication system based on high temperature fluorinated grease which solves a long standing industry proven with re-circulating oil lubrication system, with elimination of lubricating oil system, the wastage of oil and leakage on the floor is prevented. Two Pre Heaters are provided with the Machine. It has unique slide roll system, with corrugating rolls mounted on two sides of one frame, allows a complete roll changing less than 30 minutes. Flute changing is fast, simple and safe. Once the roll carriage is in place there are no adjustment to be made and no fine tuning is required.

Paper Packaging Box Making Machine

400,000 - 2,500,000 Per SET

Paper Packaging Box Making Machine, Die Cutting Machine, Platen Punch Machine

Corrugated paper making machine

Get Price Quote

Corrugated paper making machine, Box Stiching Machine

paper board making machine

Get Price Quote

paper board making machine, Paper Machinery, paper slitting machines

Paper Making Machine

Get Price Quote

Paper Making Machine

Paper Carry Bag Making Machine

Get Price Quote

Paper Carry Bag Making Machine, Die Cutting Machines

Paper Bag Making Machine

Get Price Quote

Paper Bag Making Machine, Window Cum Plain Lamination Machine

Combined Paper Corrugating Board Making Machine

Get Price Quote

Combined Paper Corrugating Board Making Machine, granulator blades

Combined Paper Corrugating Board Making Machine

Get Price Quote

Combined Paper Corrugating Board Making Machine, Eccentric Slotter Knife

Toilet Paper Roll Making Machine

Get Price Quote

Toilet Paper Roll Making Machine, plate bending rolling machine

Paper Making Machine

Get Price Quote

Paper Making Machine, paper converting machine, Pulper Machine

Paper Making Machine

Get Price Quote

Paper Making Machine, Flour Mill Plant, Mini Flour Mill, mini pulverizer

Paper Bag Making Machines

Get Price Quote

Paper Bag Making Machines, Die Cutting Machines, Embossing Machine