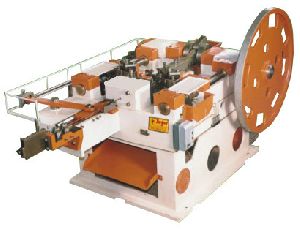

Barbed Wire Making Machine

Get Price Quote

Features : simple, sturdy & robust in designeasy to operatecapable of making barbed wire of two ply and four barbsindigenous productionassembled with multiple gears and loversaccurately timedperforms the multiple function of feeding, barbing, twisting, cutting & coilingworks without the aid of manual labor technical specifications : capable of making g.i. Wires of 3 types :main ply two lines of 12g with 4 barbs made 12g wire at distance of about 3” or 75mm apart.main ply two lines of 12g with 4 barbes made of 14g wire at distance of about 3” or 75mm apart.main ply two lines of 14g with 4 barbes made of 14g wire at distance of about 3” or 75mm apart.production : 500 to 600 kgs per shift of 8 hours.electric motor : 5 hp. X 960 rpmspace required : 15 ft. X 12 ft.weight : 1000 kgs approx.acessories : 4 nos. Wire stands. Installation : it is easy and simple to install the machine. The machine’s stands should be securely bolted to the foundation and the machine should be accurately aligned and leveled.

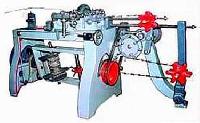

Wire Stitching Machine

Get Price Quote

Easily maintained,sturdy build up it is meant for stitching blocks of cuurency notes ,booklet and books.Nicely presented with best performance the machine mechanism is very sturdy. The distinguished performance results no wastage of time and production.The machine is very economic for commercial production and maintance

Best Deals from Wire Making Machines

Wire Drawing Machine

150,000 Per Piece

3 HP Barbed Wire Making Machine

130,000 Per Piece

1 Piece (MOQ)

Semi Automatic Wire Book Stitching Machine

Get Price Quote

1 Piece (MOQ)

Automatic Wire Nail Making Machine

Get Price Quote

We are a well-known name as Automatic Wire Nail Making Machine Manufacturer, Exporter and Supplier in Punjab (India). The SMT Automatic high-speed Wire Nail Machines are made from high-grade castings and steel. Our Automatic Wire Nail Making Machines are simple and sturdy in design for friendly use. With advanced features, the Wire Nail Machines are known for their long lasting service. Automatic Wire Nail Making Machines can produce nails from H.B. brass, copper and aluminium wires. All the movements except the pressure for gripping and the ejection, are through cranks, which are essential for smooth running at high speeds maintaining full rate production of well finished nails. Special attention has been given to maintain easy approach to all the required adjustments and settings. Our Automatic Wire Nail Making Machines are available at very reasonable prices. Technical details : Inch 11 -2 -31 42 52 62 8 Gauge 20-1718-1416-1214-912-810-68-48-2 Type Unit SMT WN-1 SMT WN-1.5 SMT WN-2 SMT WN-3 SMT WN-4 SMT WN-5 SMT WN-6 SMT WN-8 Length of Nail mm 6.0-25.4 12.0-38.0 12.0-50.0 20.0-75.0 25.0-100.0 50.0-125.0 50.0-150.0 50.0-200.0 Wire Gauge mm 0.9-1.4 1.2-2.0 1.6-2.6 2.0-3.7 2.6-4.0 3.5-4.6 4.0-6.0 4.0-7.0 Output Pcs/Min 500-550 400-450 300-350 225-275 175-210 175-200 100-125 90-100 Power Required HP 1.0 1.05 2.0 3.0 5.0 5.0 7.0 10.0 Net Weight Kgs 225 350 500 850 1200 1500 2000 2500 Over all Dimensions(L*B*H) Inch 33*29*32 33*32*35 36*37*37 47*56*42 52*51*44 58*62*46 65*72*49 84*77*54 Note : *All specifications are subject to change without any prior notice.

Barbed Wire Making Machine

Get Price Quote

Tensile Stregth: H.B. Fully Hot Dipped Galvanized wire with under 30 kg. F/MM to 55 kg. F/MM capacity/production: 6 Qtl/8 HR shift exclusive maintenence for 12/12swg. Wire keeping 140 to 220 barbs min with length to coil maximum 400 meters & weigth per bundle 40/50 kg. (bundle size 16" x 10") Width Barb Spacing: 3 to 4" pitch also adjustable with additional gears in winding unit which ever could be supplied only under special demand. Our Major emphasis are laid down upon its adjustibility of parts easy maintenance operator has wasy approach in setting all arms, cutters making the machine parts fool-proof it ensures easier dismantling, assembling, loading, unloading as well consequent view over flow of formed wire, all the adjustable parts are all together accessible and machine is supplied along with a set of spare twisting sleeve, Take up real, pay off stands, it requires 5 H.P. slow speed 3 H.P. 50C/S squirral eage induction motor with reversible starter whichever is not supplied with the machine it is designed in its heavy structure using closed grain castiron & steel in EN-36 series, all the gears are processed by bevel genrator & hobbing machines 15 Qtl enclusive of Pay-off stands.

Wire Nail Making Machine

200,000 Per Piece

Automatic High Speed Wire Nails Making Machine Model SE-3

Get Price Quote

This machine is manufactured for the production of wire nails of length from 0.5 inches to 3 inches. It produces upto 300 nails per min.

12mm Double Head Wire Book Stitching Machine

Get Price Quote

Wire Ring Making Machine

Get Price Quote

Wire Nail Making Machine

155,000 Per Piece

1 Piece (MOQ)

Perfect Automatic Wire Nails Making Machines are simple and sturdy in design are made from high grade casting & steel. These machines can produce flat head nails, pop nails, round head nails, lost head nails, counter shank head nails, from H.B, copper, aluminium & brass Wires. Drive: Its main crank is directly driven by motor and side-shafts are driven by four bevel gears to ensure correct and permanent adjustment of the cutting tool. The length and thickness of the nails is adjustable. All tools are easily accessible and can be quickly changed. its main and side shafts are fitted with browns bushes to ensure long life. All comes, gears, rollers, roller pins are made from high-quality steel properly heat-treated and grounded for long lasting. Working Of the Machine : The wire end from coil passes throughtening rollers and fed intermittently in the gripping dies, which close firmly allowing heading punch to press the head of the nails, then grip loosened and required length of the nail is fed constantly, where it is cut by cutting tools leaving ample stock for the head of the next nail. Thus ready nail is ejected by the ejector. The operations are repeated in each revolution. Note: Due to constant improvement, we reserve the right to change / modify any machine. (S.W.G.)Production (per minute)PNM-1.51/2" X 1.5" (12 to 38 mm)18-14400-450PNM-21/2" X 2" (12 to 50 mm)16-12300-350PNM-33/4" X 3" (20 to 75 mm)14-9225-275PNM-41" X 4" (25 to 100 mm)12-8175-210PNM-51.5" X 5" (35 to 125 mm)10-6110-125PNM-62" X 6" (50 to 150 mm)8-4100-125PNM-82" X 8" (50 to 200 mm)8-290-100

Barbed Wire Making Machine

Get Price Quote

1 Set(s) (MOQ)

1. Main ply two lines of 12G with 4 barbs made 12G wire at a distance of about 3� or 75mm apart. 2. Main ply two lines of 12G with 4 barbs made 14G wire at a distance of about 3� or 75mm apart. 3. Main ply two lines of 14G with 4 barbs made 14G wire at a distance of about 3� or 75mm apart.

Treadle Driven Wire Stitching Machine

Get Price Quote

We are a major Manufacturer, Exporter & Supplier of Treadle Driven Wire Stitching Machine. The Treadle Driven Wire Stitching Machine is widely used for stitching blocks like currency notes, booklets, books, etc. The specially designed mechanism of the Treadle Driven Wire Stitching Machine lends a flawless look and sturdiness to the end product. The Treadle Driven Wire Stitching Machine gives higher output without any wastage of time and resources. Best suited for commercial production, the Treadle Driven Wire Stitching Machine is compact, durable, efficient, reliable and easy to maintain.

Power Operated Wire Book Stitching Machine

Get Price Quote

We make available Power Operated Wire Book Stitching Machine that consumes less power and easy to operate. We are enlisted among the reputed Manufacturers, Exporters and Suppliers of Power Operated Wire Book Stitching Machine. It is manufactured under the supervision of industry experts. Thus, our Power Operated Wire Book Stitching Machine is the perfect option on which buyers can easily rely. One can obtain Wire Book Stitching Machine from us at the best market price.

ALLIED BRAND BARBED WIRE MAKING MACHINE

Get Price Quote

We are offering allied brand barbed wire making machine. Adjustibility of parts easy maintenance operator has wasy approach in setting all arms, cutters making the machine parts fool-proof it ensures easier dismantling, assembling, loading, unloading as well consequent view over flow of formed wire.

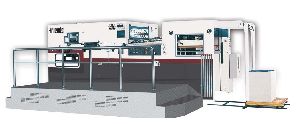

Die Cutting and Creasing Machine with Stripping

4,500,000 - 7,500,000 Per Piece

1 Piece (MOQ)

Stripping Part Match with the centerline registration system, molde is changed easily and accurately. Double action movement structure and male/female mode are available for different products. The edge gripper paper waste system realises the four edges waste stripping. Lead Edge Feeder Free-Pressure lead edge feeder can prevent the surface of the cardboard from damaging by leader. High precise servo system provide the power independently, this can assure accuration and stabilize of the cardboard.

Geared Sheet or Wire 4 Legs Folding Stand Machine

Get Price Quote

Length of roller 5" 5 12" 6" 7" die of roller 2 34" 3" 3 14" 3 12" h.p. Required 1.5 1.5 2 2 price without moter & v-belt ₹ 32800 ₹ 34700 ₹ 38500 ₹ 53000

wire nail making machines

Get Price Quote

Owing to rich industry experience, we offer Wire Nail Making Machines to our clients. These machines are manufactured using advanced technology and quality components which are procured from our vendors. The product is manufactured under the supervision of our skilled and experienced workers. These are in accordance to the standards as well as manufactured using supreme quality materials supplied by our vendors.Features: High tensile strength Corrosion-resistance Unmatched performance Other Details:Construction: The main frame is of high grade cast iron and all leavers and other components subject to heavy duty are manufactured from high quality steel and designed with high safety factor. Main Drive: Operating mechanisms are to longer mount on one common shaft but on two auxiliary shafts thus eliminating long cutter leaver The cutter slides move in substantial guides and driven directly by cranks a centric This avoids all detrimental impacts of the cutter against each other consequently reduces cutter wear Crank Shaft: The Crank Shaft is carried in four Bearings. The smooth ruining of the nail machine is thus ensured

Wire Binding Machine

Get Price Quote

SIKANDAR MACHINES offers Thread Book Sewing Hand feed & Semi Automatic, PLC & AC drive controlled Perfect Binder Machine for title book binding & spiral, wiro,plastic comb Round holes, square & rectangular punches for diaries, calenders, booklets manufacturers.Various dies fitable on the power press for Heavy production