vibro shaker

Vibro Shaker, manufactured by us, is a low cost, versatile equipment to test the pigments in paints, inks, textile pests & dry dispersion. Most of the inks and paints except paste inks having very high viscosity can be prepared with this equipment. Vibro Shaker Machine, offered by us, is much faster than the sand mill. There is no loss of solvent and so repeatability of the test can be easily established. It has two dimensional vigorous shaking and vibrating movements by which pigment particles are subjected to high shear and impact force. Glass beads, steel balls & cylinders, etc. can be used as grinding media in vibro shaker. Today, we are reckoned as one of the foremost Automatic Vibro Shaker Exporters and Suppliers. This is a low cost, versatile equipment to test pigments in paints, inks, textile pests & dry dispersion. Technical Specifications For Marking Small amount of inks, paints, Textile pastes & dry dispersion.ASTSM Specified test can be performed.650 oscillation/ minute (reciprocating & tilting)No solvent or material lossAvailable in four Sizes : 125ml, 250ml, 500ml, 100mlAlso available with battery backup timer facilityElectronic digital timer.Use & throw flacons of polypropylene no contamination, easy tareReproducible resultsMachine Dimensions : 50cm X 78cm X 55cmMachine Weight : 74kg (approx.)Gross Weight : 115kg (approx.) This is not so costly versatile equimpment used to test pigment in paints and inks. By ASTM specified test methods, most of the inks and paints except paste inks can be prepard in this equipment. It is much fater than the sand mill. There is no loss of solvent and so repeatability of the test can be easily establishe. It has two dimentsional vigorous shaking and vibrating movements at 50 oscillations per minute reciprocating & tilting by which pigment particles are subjected to high shear and impact force. Glass beads, steel balls or cylinders can be used as grinding media. In 125ml attachment 8 samples can be tested at a time. We provide disposable PP Flacons to aviod cross contamination & ease of use. We can provide 4 attachments with the machine i.e. 125Ml, 250ml, 500ml, 1000ml.

...more

twin roll mill

Twin Roll Mill is a useful machine for testing pigment or solvent dye for its use in any polymer from rubber to plastics like LDPE, HDPE, PP, PS, PC ABC, etc. In Electrical Twin Roll Mill, there are two rollers separately heated by electric heaters and can be masticated precisely in precise time at controlled temperature and pigment is mixed &dispersed in it. It is possible to control nip gap by precision screw and knob and can be checked by filler gauge. Display board is provided for digital display of both temperature and timer for masticating time precise testing of standard and sample can be done over this machine. We also provide doctor�s blade to take out the lump of polymer prepared on the mill. From this lump measured piece of sample is taken and is compression molded on hydraulic press to form a fine chip. To avoid time delay separate heating and cooling zones are provided in the press. The die filled with material is subjected to high pressure in the heating zone and then is transferred to cooling zone to solidify under pressure. This gives very finish and flat chip. These are very versatile machines for testing pigment in plastic application and also for testing masterbatches on lab scale. Today, we are considered as one of the prominent Two Roll Mill Manufacturers and Suppliers. This is a unique equipment to test pigments in various plastic & rubber applications. It is used in combination with lab scale Hydralic. This machine is used normally in combination with hydraulic Press. These machines are used to test the performance of pigments or polymer soluble dyes in different plastics & rubber like LDPE, HDPE, PP, PS, PC, ABS, Natural rubber, EVA rubber etc. In twin roll mill, there are two rollers separately heated by electric which masticates the Polymer mass uniformly in precise time at controlled temperature and friction ratio. A pigment is mixed & dispersed in it. It is possible to control nip gap by precision screw and knob and cab be checked by filler gauge or digital nip gap device. Display board is provided for digital display of both temperature and timer for masticating time. Doctor's blade is provided to take our the lump of polymer prepared on the mill. This machine in combination with Hydraulic press has become vital testing & shade matching equipment for plastic & master batch industries. Highlights : Worldwide accepted testing methodSaves cost of testing, time & energyQuick formulations os useful for R & D Very consistent & dependable results Any polymer like LDPE, HDPE, PP, PS, PVC, PC, ABS, HIPS, PET, PBT Natural Rubber, EVA Rubber can be tested Digital nip clearance adjustment readout for left & right side Digital timerVariable roller speed & digital read out Specially designed doctor's blade for efficient vertical & horizontal mixing factor Close temperature controlCentral water cooling for immediatre tem perature change Knee operated stop 'n' reverse emergency safety deviceImported lubrication free gearing materialWorld standard electrical & electronic control devices

...more

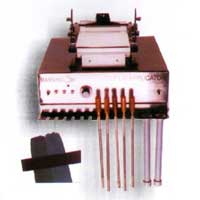

turbo injection mill

We manufacture Turbo-Injection Mill (Lab. Horizontal Bead Mill) that is designed to make small laboratory dispersion samples while using minimum amount of raw materials. Herein, the samples are grounded, premixed, poured into feeding funnel. These materials further moved into water cooled milling chamber having 70-85% of the void volume with small grinding beads approximately 1 mm diameter. The rotation of the agitator and subsequent movement of the media creates shear and impact forces upon the turbo-injection concept for efficient particle and agglomerate reduction. A screen located at the chamber end retains the beads while the diverter end plate allows the product to either re-circulate back to the feed funnel or exit in a single pass. Samples can be taken at intervals and tested for quality. Why our Turbo-Injection Mill? Speedy solution to testing difficultiesHandling of wide range of viscositiesEasy to dismantle and reassembleRequire low maintenanceCompetitive pricing Fast Features Efficient development of new formulationsReliable raw materials quality controlRapid assessment of customer problemsSpeedy solution to testing difficultiesHandling of wide range of viscosities MachineMotor (H.P)Bead ChargeSample SizeTIM - 1003 H.P60 - 80 ml100 - 300 ml Working Principle Operation Mode The sample is premixed either by hand or by shaker and is simply poured into the feeding funnel with the �Marshal� Turbo-Injection Mill. Herein, either the material is collected after each pass through the Turbo-Injection Mill that is single pass method or else the material is fed directly back into the feeding funnel from the outlet of the milling chamber which is re-circulation method. Input Mode For charging or changing the beads rapidly there are input & outlet ports fitted with the chamber. Larger funnels with pressure lids and pressure plunger are also available with us. Single Mode Beginning as in the re-circulation mode, once recirculation is established, the machine RPM is increased to the desire level and the end plate diverter can then be set to single pass. By rotating the end plate slightly, the throughput rate can be adjusted from maximum to minimum flow rate. Re-circulation Mode With the end plate set to re-circulate, the RPM is increased to desire level and product allow re-circulating until the degree of product quality is achieved. Product is removed from the mill by turning the end plate diverter to the single pass outlet position. Cleaning Mode Addition of suitable solvent to the feed funnel with the end plate in the re-circulation position allows for quick and efficient cleaning of the mill. No dead zones - for rapid cleaning by solvent throughput only. Components can be quickly dismantled for complete cleaning when necessary. Cooling Large area having circular jacket over the mixing zone that renders optimum effects. Also effective cooling in the grinding chamber for improving the dispersion results in research & product development. Applications PaintsInk & CoatingsPharmaceuticalsPigmentsBiotechnologyFoodstuffsTextilesCosmeticDetergentsAgrochemicals The 'Marshal' Turbo-Injection Mills have been designed for the most efficient wet milling at laboratory / pilot / production scale for dispersion up to even sub micron or nano size. In the lab model, sample to be ground is per-mized and poured into the feeding funnel. The feed screw pumps the material to move it into the milling chamber. The water cooled chamber is filled with small gri9nding beads (Zirconium Oxide) of appropriate size. The rotation of the agitator and subsequent movement of the media creates more of shear and less of impact forces upon the turbo � injection concept for efficient particale and agglomerate reduction. A screen located at the chamber end retains the beads while the diverter end plate allows the product to either recirculate back to the feed funnel or exit in a single pass. Samples can be taken at intervals and tested for quality. Purging with the cleaning materals and quickly dismantling the components can be done easily with quick release closures. Fast Features : One of the most efficient wet milling technology.Higher throughpur with higher energy efficency Efficient development of new formulations. Speedy solution for efficient particle size reduction.Can even grind up to sub micron level.Handling of wide range of viscosities.Cleaner process control. Easy material handling

...more

Triple Roll Mill

Triple Roll Mill, manufactured by our company, is equipment that uses the shear force created by three horizontally positioned rolls rotating at opposite directions and at different speed relative to each other to mix, refine, disperse, and homogenize viscous materials fed into it. Hydraulic Triple Roll Mill is extensively used and can be availed at very pocket friendly price. Our company has become one of the proficient Laboratories Triple Roll Mill Exporters. A Triple Roll Mill is equipment which uses the shear force created by three horizontally positioned rolls rotating at opposite directions and at different speed relative to each other to mix, refine, disperse, and homogenize viscous materials fed into it. Technical Details We are manufacturing fully hydraulic Triple Roll Mill for Laboratories; research Application and small Scale Productions : Roll Size : Diameter 120 mmWorking length : 250mmRoller Speed Ratio : 1:3:9Roller Material : High Carbon High Chromium.Hardness : 62 HRCGround & Polished as required (mirror finish)By Electro Hyraulic System the both rollers (Feed roll and take off roll) can be operatedBoth Hydraulic Pressures up to 30kg/cm2Electronic Digital Temp IndicatorCenteral Water CoolingElectronic digital timer.Electrical : 1.5 HP Three Phase, 415 voltsMachine Dimensions : 110cm X 66cm X 116cmMachine Weight : 450kg (approx.)Gross Weight : 510kg (approx.) To prepare viscous paste inks like offset ink; this lab/pilot model of triple roll mill is used. The formulation is sub-jected to high shear force between the two rollers moving with different speeds. The third roll is use to take off the preparation. The rollers require super finish and adequate hardness. Side covers are provided to avoid splitting ink over the side bush. The nip gap is controlled by the Controlled by the hydraulic pressure provided individually on both the rollers. Pressures of the rollers are displayed by pressure gauge at the top. This equimpment is very useful to set production parameters by taking trials and standardizing on this lab model. Fully hydraulic three roll mills can be used for many different applications. They are most suitable for a wide range of medium to high viscosity products, e.g. All kinds of printing inks, artists colors, industrial and decora tive paints, toners, coating masses and lubricants, but also for materials for the electronics and cosmetics industries. Three roll mills are designed for meeting highest quality demand and at the same time enable convenient, easy operation and quick eleaning.

...more

textile emulsion testing equipment

Square Applicators

Darteno Industries offers a wide range of Pigment Testing Accessories that mainly includes Wire Bar Coater (No. 1 to 8), �C� type Applicator, Four Side applicator, Mass tone scrapper, Ink scrapper, Manual applicator Hand pad, Grinding Pad, Flow Gauge kit, Kit, Drawdown Cards, etc. These pigment testing accessories are extensively used in varied industries. We have established our self as one of the ace Pigment Testing Equipment Manufacturers from India. Accessories : Wire Bar Coater (No. 1 to 8) �C� type Applicator Four Side applicator Mass tone scrapper Ink scrapper Manual applicator Hand pad Grinding Pad Flow Gauge kit Kit Drawdown Cards

...more

sigma kneaders

Sigma Kneaders that we are offering are specially designed for achieving desired results in High Sheer wet milling, Pigment flushing or even high viscous mixing. Our MARSHAL’ Sigma Kneaders are manufactured from superior grade components and in compliance with the set industrial norms and standards. The performance deciding features are well studied, giving high performance yet low maintenance. We are a prominent Sigma Kneaders Manufacturer, Exporter and Supplier from Gujarat, India. We make them available in various sizes and specifications. Features Optimum nearest blade to wall distance Maintenance friendly stuffing box design Hydraulic tilting arrangement Easy Lid opening Mechanism High tensile blades for high Sheer force requirements. Stringent Quality Control (X-Ray Test, Stress Test & Inter granular Corrosion Test) Ideal Blade helix angle with superior blade design for High sheer applications Application specific customization Applications Pigment Dispersions Pigment Manufacturing Flushed Pigments Epoxy-putty Rubber solution & adhesives Soap Chewing gum Stationary Colors Ointment Plastic Compound Activated Carbon Sizes Available 5 Litres 200 Litres 450 Litres 1000 Litres 2000 Litres

...more

Regular Model

'Marshal’ - Twin Roll Mill (Economic Model) Model : Laboratory Twin Roll MillRoller size : 110 mm dia * 312 mm total length made of alloy steel hardened and ground hard chrome plated.Working length of Roller : 250 mm min.Type of structure : Totally enclosed base and top body frame, only rollers are visible.Roller speed : 24 r.p.m. + - 0.5Friction ratio : 1: 1.2Adjustable nip clearance : 6 mm. Max., 0.35 mm minTemp control of rollers : Both rollers are separately heated directly by electrical heaters. Programmable temperature controller for each roller. Maximum Temperature 280C. Sensor: PT100.Cooling of the Rollers : By tap water circulation at the core of the rollers separately.Gearing materials : Bull gears are made of hardened alloy steel while the reduction gear is BONFIGLIOLI ROTOMOTIVE, ITALY make helical gear motor. Power: 2.2-2.5KWElectrical and Controls : Drive motor and heaters are well protected by L & T Siemens controls. Temperatures of rollers are displayed over dashboard separately. The timer is provided for the rollers, which can control the mastication time.Emergency safety : To prevent accidental mishap, knee operated safety stop and instant reversal of rollers protection is provided so that anything going inside can come out immediately. One more safety device can be provided at request, over the rollers, this can be operated with a hand touch.

...more

plastic testing equipment

planetary mill

Planetary Grinding Mill is characterized by very fast and effective comminution of shear & impact micronizing. Planetary Mars Mill is ideal for lossless comminution down to extremely high levels of fineness. The grinding can take place in dry suspension. It is well suited for mixing and homogenizing emulsions and pastes or for mechanical alloying in materials research. Today, our company is one of the primary Planetary Mill Exporters and Suppliers. �Marshal� Mars Mill is a vibration less compact tabletop machine useful for making small amount of all types of inks, paints, textile paste and also dry dispersion. The uniqueness of this machine is that this machine can make any formulations within few seconds. In India we are the only manufacturer of this equipment. This equipment saves great amount of time and cost. One identical formulation made in VibroShaker takes 1 hour for below five micron grinding and the Mars Mill makes the same formulation in 286 seconds. In Marshal Mars Mill you can also test offset ink (40 poise resin viscosity), which you can make only in triple roll mill while other devices like shakers can only make liquid inks, Mars Mill can make thick paste formulations too. In other equipment testing you have to wash your steel beakers thoroughly to prevent cross contamination which is very expensive, useless, additional cost in pigment testing. On the other hand with this machine we provide disposable plastic flacons (cups) in which you test your specimen and after taking draw downs you can throw it away because the cost of a flacon is negligible. Additionally, sometimes it happens that customers do not provide sufficient amount of pigment standard samples for testing purpose so to test in any other wet grinding equipment we need almost six times more amount of pigment than in Mars Mill. In Mars Mill we can make the batch of any formulation as small as 20 gm using less than 0.5 gm of pigment. This mill is characterized by very fast and effective comminution (combo effects of shear & impact micronizing). It has a wide range of applications. It�s ideal for lossless comminution down to extremely high levels of fineness. The grinding can take place dry, in suspension. It is well suited for mixing and homogenizing emulsions and pastes or for mechanical alloying in materials research. Mars / Planetary Mill is characterized by very fast and effective comminution by shear & impact force. Mars mill is ideal for comminution down to extremely high level of fineness without material loss. The grindling can take place in dry/wet suspension. It is well suited for mixing and homogenizing emulsions and pastes also for mechanical alloying in material research. 'Marshal' Mas Mill is a vibrationless compact talbetop machine useful for making small amount of all types of inks, paints, textile paste and also dry dispersion. The uniqueness of this cmachine is that this machine can make any formulations within few seconds. This equimpment saves great amount of time and cost. The machine is provided with electronic digital timer for errorless testing. In Mars Mill you can also test thick pasty medium, which you an make only in high energy mills. To prevent cross contamination, we provide disposable PP Cup along with the machine. Very small amount of samples (up to 20ml) can be prepared in this machine. Machine dimensions : 29cm x 42 cm x 43 cm.

...more

Planetary Ball Mill

Being one of the reliable Manufacturers, Exporters and Suppliers, we bring forth the Planetary Ball Mills with Four Stations to the clients. Planetary Ball Mills are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the Planetary Ball Mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of the Planetary Ball Mills result in very high pulverization energy and therefore short grinding times. Planetary Mill is characterized by very fast and effective comminution by shear & impact force. This Mill is ideal for comminuting down to extremely high level of fineness without material loss. The grinding can take place in dry/wet suspension. It is well suited for mixing and homogenizing emulsions and pastes also for mechanical alloying in material research. Our Planetary Ball Mill is a vibration less machine useful for making all types of inks, paints, textile paste and also dry dispersion like various composites. The uniqueness of this machine is that this machine can make any formulations within short time. This equipment saves great amount of time & cost and is provided with electronic digital timer for errorless testing. Suitable For Alloys, bentonite, bones, carbon fibers, catalysts, cellulose, cement clinker, ceramics, charcoal, chemical products, clay minerals, coal, coke, compost, concrete, electronic scrap, fibres, glass, gypsum, hair, hydroxyapatite, iron ore, kaolin, limestone, metal oxides, minerals, ores, paints and lacquers, paper, pigments, plant materials, polymers, quartz, seeds etc. Features Powerful and quick grinding down to nano range Dynamically balanced for unsupervised operation Comfortable parameter setting via display panel Programmable starting time Reproducible results due to energy and speed control Different types of grinding can be done with dry and wet material Wide range of materials for contamination free grinding Safety enclosure is provided for ease of operation

...more

pigment testing accessories

Darteno Industries offers a wide range of Pigment Testing Accessories that mainly includes Wire Bar Coater (No. 1 to 8), �C� type Applicator, Four Side applicator, Mass tone scrapper, Ink scrapper, Manual applicator Hand pad, Grinding Pad, Flow Gauge kit, Bomb Kit, Drawdown Cards, etc. These pigment testing accessories are extensively used in varied industries. We have established our self as one of the ace Pigment Testing Equipment Manufacturers from India. Accessories Wire Bar Coater (No. 1 to 8)�C� type ApplicatorFour Side applicatorMass tone scrapperInk scrapperManual applicator Hand padGrinding PadFlow Gauge kitBomb KitDrawdown Cards

...more

Paint Testing Equipment

Model - I Pressure By Leverage

Technical Details : Marshal Automatic Pigment Muller :(Model-1) (Pressure by Leverage)Well Known and proven Engelmann’s type MullerGrinding Glass Diameter : 250mmNon-contact Type electronic digital counterWith all SS leversElectrical : 0.5 HP single phase 220 volts, 50HzMachine Dimensions : 70cmX69cmX40cmMachine Weight : 100 kgGross Weight : 138 kg

...more

Model - 2 Pressure By Spring Loaded Cartridge

Marshal Automatic Pigment Muller : (Model-2) (Pressure by Spring Loaded Cartridge)Stainless Steel BodyMeasured amount of pressure can be givenNon-contact type electronic digital counterGrinding Glass Diameter : 185mmElectrical : 0.5 HP single phase 220 volts, 50 HzMachine Dimensions : 60cmX40cmX70cmMachine Weight : 61 kg.Gross Weight : 102 kg.Accessories with the Mmachine : Extra Glass Pair-1Set

...more

Hydraulic Press Machine

We offer Hydraulic Press Machine in two basic models. One is economic model and the other one is advanced model. These Automatic Hydraulic Press Machines possess various technically advanced features that distinguish them from each other. We offer hydraulic press machine at very competitive price with that we have carved a niche for ourselves among the pre-eminent Digital Hydraulic Press Machine Manufacturers and Suppliers. ‘MARSHAL’- Hydraulic Press (Economic Model) Pillar type : Capacity 150Kg/cm2 Die size : 200mm X 200mm Electric heating & tap-water cooling Digital temperature controlling system. Heaters are provided on both the plates with temp controller. Power : 1.6KW. Sensor: PT100. Any polymer having softening temperature ranging from 40oC-280oC can be tested. A power-pack is also provided. Separate heating and cooling zones. Electric motor 2 HP three phase 415 volts, 1.5KW Machine Dimensions : 92cm X 79cm X 143cm Machine Weight : 420kg Gross Weight : 539kg Total Power : 3.2 KW ‘MARSHAL’- Hydraulic Press (Advance Model) Pillar Type : Capacity 300kg/cm2 Die size : 200mm X 200mm Maximum Temperature Achievable : 300oC Automatic opening and alarm after preset time both heating & cooling zones. Separate heating and cooling zones: special cooling facility in heating zone also. Digital pressure readout. Digital temperature indicator for cooling zone. Digital temperature controller for hearting zone. Down movement by push button This machine is used normally in combination with Twin Roll Mill. These machines are used to test the performacne of pigments or polymer soluble dyes in different plastics & rubber like LDPE, HDPE, PP, PS, PC, ABS, Natural rubber, EVA rubber etc. From the melt prepared in Twin roll mill, measured piece of sample is taken and is compression molded on hydraulic press to form a fine chip. To avoid time delay separate heating and cooling zones are provided in the press. The die filled with material is subjected to high pressure in the heating zone and then is trasferred to cooling zone to solidify under pressure. This avoids warping &gives good finish and indicative chip. This machine in combination with Twin Roll Mill has become vital testing & shade matching equipment fo rplastic & master batch indus tries. Highligths : Separate heating & cooling zones to cut short the time cycle of compression moulding Pressure up to 250 kg/cm² Even heating throughout the heating zone Solenoid operated up & down movement of the plates Digital timer operated automatic opening of die plates Digital pressure gauge World standard electrical & electronic control devices

...more

Horizontal Disc Mill

Owing to our rich industrial experience and sophisticated manufacturing unit, we design a qualitative assortment of MARSHAL Horizontal Disc Mills in various sizes and specifications. Our Horizontal Disc Mills are ideally constructed to provide mill & disperse pigment particles into paint or ink media giving excellent coloristic properties & particle size. They are user friendly and equipped with numerous safety oriented mechanism makes it useful in rugged performance on shop floor. We are a renowned Horizontal Disc Mill Manufacturer, Exporter and Supplier from Gujarat, India. Buy them from us at reasonable prices. Features Higher throughput with higher energy efficiency Can even grind up to sub-micron level Double acting mechanical seal Easy Material handling - reduces labor cost Unique centrifugal bead separation system Narrow Particle size distribution Grinding Media: 0.6 mm - 2 mm can be used Applications Liquid Inks Solvent / Water base Dispersion Agro Chemicals Pharmaceutical formulations Paints Sizes Available 4 Litres 10 Litres 30 Litres 50 Litres

...more

high speed dispersers

We have excelled in the business of manufacturing, exporting and supplying High Speed Dispersers. The High Speed Dispersers that we offer is a new, powerful and innovative generation of Lab-pilot-plant machines for mixing with maximum process control. Designed by professionals, the High Speed Dispersers is equipped with three-phase motors, which on require a three phase power supply. These motors ensure a smooth start, and have infinitely variable speed. The ‘Marshal’ Hi-speed stirrers are very quiet during operation. The motor & control panel is fully flame proof for avoiding the accidents. Our High Speed Dispersers has the new stylish and sturdy stand with mechanical height adjustment. The compact instrument control box is conveniently mounted on the stand. The central clamping system – part of the safety device – makes it safe and simple to hold the dispersion container securely in position. The container is placed on the laboratory bench between the clamping arms and is automatically centered as the arms are tightened. Our High Speed Dispersers is suitable for many different stirring tasks such as homogenization of liquid mixtures. With low or medium viscous products wall distant stirring tools such as propeller blades or dissolver discs can be used. For higher viscosities a complete mixing of merging liquids is only possible with a wall near stirring tool such as a butterfly stirrer. Features Chamber volume capacity range from 1 to 150 liters Additional Variable speed control facility is available to process variety of viscosity RPM range 150 to 3500 adjustable in VFD facility (depending upon to chamber volume) Jacketed S.S 304 container with S.S lid split type Fully flame proof motor & control box for processing safety Digital RPM read out on control panel in VFD facility only We can provide different types of discs as per your application Height adjustment by mechanical system

...more

Filter Test Machine

We are specialized in manufacturing, exporting and supplying Filter Test Machine of world class quality. For quite a period screen life tests for rating the quality and dispersibility tests of colorants in polymer melts have been performed. But the comparison of those test were poor. Now, the draft of the new standard EN 13900-5 describes a procedure which increases the comparability of those tests. On one hand this standard describes which kind of extruder, melt pump, sieves and breaker plate have to be used and on the other hand the composition of mixture, the test routine and the evaluation is described. One parameter, the filter pressure value 'FPV' describes the quality and dispersion of the pigments. Due to standardized quality control an improvement of the products is possible. Also the ranking of the same products from different vendors by comparing the FPV results is now easier. The use of the FPV test to check raw materials ensures the quality of your products and the up time of screen changers is more predictable. Application & Operations The procedure is suitable for testing colorants in the form of color concentrates in all polymers used for extrusion in melt-spinning processes. The test mixture is processed in a single screw extruder with a non-grooved barrel and a compression screw with now additional mixing elements. The polymers melt is fed with a constant pressure of 30 to 60 bar (435 to 870 PSI) to the melt pump with a volume discharge of 3 cc / revolution. Particles and agglomerates over a certain size are retained and clog the filter package. A pressure increase is observed and is correlated with the quality of the colorant. The pressure difference between the initial pressure and the peak pressure is used for the calculation of FPV filter pressure value. Computerized Control Of Filter Pressure Testing Machine With the Filter Test Machine the recording and controls are made with an on-board Panel PC with screen. The control panel is also equipped with an in house made electronic circuit which registers and controls signals form pressure transducers and thermocouples. The test parameters can be keyed in on a very practical key board with large scroll Mouse on a pull out drawer. This feature is a lot easier to use, since the running parameters and batch data can be keyed in on the key board in the same way as with a normal PC. The PC can store nos. of test results, which can be obtained in printable media by connecting a printer. Result And Evaluation : The filter pressure value (FPV) is defined as the increase of pressure per gram colorant and calculated using by the following equation : FPV = (P max-Ps)/mc = [bar/g] Where, FPV-Filter pressure value (bar/g), PS-Start Pressure in bar, P max – Maximum Press-sure in bar, MC-Quantity of colorant in gram. It is recommended to record the result accurately to one decimal place. Highlights Design as per European Standard EN 13900-5 to get very repeatable & dependable FPV value of master batech & colorants Fully computerized & SCADA operated automatic system havi no control panel on machine System with necessary safety interlocks to prevent mishap Separate pre-heating zone for breaker plate Automation developed & provided by Siemens exclusively for with distanta software system suppon through Internet Attentive aftersales support Close Temperature Control by Unique Control Devis Special long life Heat-Cool Ceramic heates wigh copper fins for sharp control of Temperature Youtube Video - http://youtu.be/xc4sEQx14gA

...more

Bar Coater

Darteno Industries offers a wide range of Pigment Testing Accessories that mainly includes Wire Bar Coater (No. 1 to 8), �C� type Applicator, Four Side applicator, Mass tone scrapper, Ink scrapper, Manual applicator Hand pad, Grinding Pad, Flow Gauge kit, Bomb Kit, Drawdown Cards, etc. These pigment testing accessories are extensively used in varied industries. We have established our self as one of the ace Pigment Testing Equipment Manufacturers from India. Accessories : Wire Bar Coater (No. 1 to 8)�C� type ApplicatorFour Side applicatorMass tone scrapperInk scrapperManual applicator Hand padGrinding PadFlow Gauge kitBomb KitDrawdown Cards

...more

automatic pigment muller

Automatic Pigment Muller, provided by us, is basic equipment for testing pigment dispersion. Automatic pigment Muller offered by us is to test pigment�s properties like strength and tone. Measured grinding is given to the pigment between two roughed glass plates by wetting it with high viscosity linseed oil. Standard and sample ground in the same conditions are taken out and after taking draw down, results are compared. It is also possible to determine complete dispensability curve of a single pigment. Automatic Digital Pigment Muller is available in the market at very reasonable price. Today, our company has become one of the well known Pigment Muller Machine Manufacturers in India. This is a basic equipment to test pigment dispertion; properties like strength and tone by measured grinding process between the glass pads. Pigment Muller is the basic machine to test pigment for its properties like, strength and tone. In this equipment, pigment wetted with linseed oil of proper viscosity is given measured grinding between two roughened glass plates. Standard and sample ground in the same conditions are taken out and after taking draw down, results are compared. It is also possible to determine complete dispensability curve of a single pigment. We can also provide water cooling system if required.

...more

Automatic Film Applicator

We offer Automatic Film Applicator in three models that include basic model, Vacuum bed attached model & Textile screen attachment. Auto Film Applicator is basically used to control variable sped and constant drawdown pressure. When the samples of ink, paint or textile paste are prepared they should be used to take proper draw down of precise uniform wet -film thickness. Without proper draw down the results cannot be accurately compared on computerized color matching system. Over this applicator it is possible to take draw downs of 12 to 150 micron wet film thickness using wire bar coater or bar applicator. By using this equipment all human errors can be eliminated. Different attachments are available for different draw down required. Today, we are considered as one of the top-most Electrical Film Applicator Exporters from India. Basic ModelVacuum bed attachment to hold the paper tight with base.Textile screen attachment to take draw down of textile paste using screen over the cloth. There are 12 different draws down speeds available to take different viscosity drawdown. Manual draw downs are often inconsistent especially between operators. This makes sample comparisons difficult or unreliable. The main purpose of using auto film applicator is precisely controlled variable speed & constant drawdown pressure. Technical Specifications Accurate, Consistent & Repeatable draw down sampling.Eliminating all human variable speed, direction & rod pressureAll Switch Operated Controls.12 different adjustable draw down speeds with electronic control .Operate with wire bar coater or bar applicator.With precision slide bearing & controlled draw down.Electrical : Single Phase 220 volts, 50HzMachine Dimensions :52cmX49cmX27cm (w/o extra attachments)52cmX72cmX27cm (with extra attachments)Machine Weight : 28Kg (Without extra attachments), 38 kg (with extra attachments) When the samples of ink, paint or textile paste are prepared they should be used to take proper draw down of precise uniform wet film thickness. Weithout proper draw down the results cannot be accurately compared on computerized color matching system. Over this applicator it is possible to take draw downs of 12 to 150 micron wet film thickness using wire bar coater of bar appline tor. By using this equimpemtn all human errors can be eliminated. Different attachments ar eavailable for different application. Vacuum bed attachment is provided to hold the paper tight with the base. This attachment is specially required for paint application. There are 12 different draws down speeds available to take differ ent viscosity drawdown.

...more

Advance Model

‘Marshal’ - Twin Roll Mill (Advance Model) Roller size : 150 mm diameter & 300mm working length of alloy steel hardened and ground hard chrome plated diamond Finish Rollers (Mirror Finish)Roller Speed : Variable Drive for individual rollers so you can set any R.P.M. of both rollers can be set separately. Digital read out for R.P.M. of both rollers.Friction Ratio : You can set any friction ratio because you can set any R.P.M. of both rollers individually.Adjustable Nip Clearance : 4 mm to 0.2mm nip clearance. Digital read out of nip clearance will be provided at both ends.Temp control of rollers : Both rollers are separately heated directly by electrical heaters. Programmable temperature controller for each roller. Maximum Temperature 280oC. Sensor: PT100. 3 KW Heaters.Cooling of the rollers : By tap water circulation at the core of the rollers individually for both the rollers.Gearing materials : Bull gears are made of hardened alloy steel while the reduction gear is Rotomotive Bonfligloli, ITALY make gear ‘Compton’ motor. Power: 2 HP, 2 nos. Motors.Electrical and Controls : Drive motor and heaters are well protected by L & T and Siemens Controls. Temperatures of rollers are displayed over dashboard Separately. The timer is provided for the rollers, which can control the mastication time.Emergency safety : To prevent accidental mishap, knee operated safety stop and instant reversal of rollers protection is provided so that anything going inside can come out immediately. One more safety device can be provided at request, over the rollers, which can be operated with a hand touch.Accessories : We will provide ‘doctors blade’ for scraping the me lt.Total Power : 7.7 KW

...more

auto film

Be first to Rate

Rate ThisOpening Hours