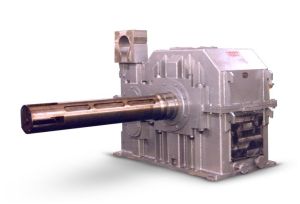

WIRE ROD MILL DRIVE

All the bearings as well almost all gear meshing are spray lubricated which are getting adequate supply of lubricating oil from common force lubrication system

...more

weight machine

The weighing and bagging machines are available in different models like gravitybeltscrew feeder or vibrating feeder tray. These machines are available as a net or gross model, in mild steel or stainless steel construction.

...more

weigh feeder controller

For additional controls and communication facility, required signals are available from the weigh feeder control panel to connect it to a PLC or a supervisory computer either direct or using MODBUS PROFIBUS etc. making it a part of distributed digital control system. Measurement of flow rate and control are all through 32 bit microprocessor based digital techniques ensuring high reliability and accuracy to the level of 0.25% which is not known in the industry presently.

...more

Weigh Feeder

For materials having sluggish flow characteristic mass flow bins, vibrators, screw feeders, rotary air lock feeders are provided to allow the material to lend themselves to control.

...more

wagon truck

Wagon truck in different models upto 3000 bags per hour are also available. The loading jib is telescopic with 180° rotation and can be lifted by a mechanical or hydraulic jack.

...more

wagon tipplers

Placement of wagon, on tippler platform, is accomplished by wagon marshalling equipment like Side Arm Charger or Bettle Charger or Pussher Car deppending on Type of Wagon Tippler application.

...more

wagon loader

WAGON LOADER To solve the ever increasing problem with handling of bags in process plants, PEL has join hands with M/s. BOUBIELA of France to manufacture Wagon and Truck Loaders. Boubiela have got to their credit, thousands of satisfied customers all over the world manufacturing/dealing in Fertilizer/Sugar/Chemicals/Cattle Feed Plants/Food Corporations etc. Different models of truck loaders up to a maximum capacity of handling 3000 bags per hour each of 50 Kgs. can be supplied for loading, stacking and lining up bags onto trucks. Wagon Loaders in different models upto 3000 bags per hour are also available. The loading jib is telescopic with 180° rotation and can be lifted by a mechanical or hydraulic jack. Simultaneous loading of number of trucks as well as wagons on parallel track can be achieved with PEL-BOUBIELA make Wagon and Truck Loaders.

...more

Uncoiler

This gear box will be exported to China through Magadh, Indore. This gearboxes are foot mounted, single stage, parallel shaft, helical gear reducer with solid input and special output shaft (in client scope of supply). This gear box has extra heavy duty Spherical Roller Bearings on output shaft to take care of the dead weight of Coil of 25 Tone as well as Coil Tension.

...more

Twin Screw Extruder Gearbox

ETS Series Twin Screw Extruder Gear Box is developed by featuring high torque and high speed output rate. The gearboxes are embedded with excellence high dissipation and oil lubrication system to provide stable output under heavy loading force. The axial thrust is supported by axial roller-type swivel thrust bearing coupled with thrust bearing assembled in tandem way. APPLICATIONS Extruder Drive Twin Screw

...more

Twin Screw Extruder

ETS Series Twin Screw Extruder Gear Box is developed by featuring high torque and high speed output rate. The gearboxes are embedded with excellence high dissipation and oil lubrication system to provide stable output under heavy loading force. The axial thrust is supported by axial roller-type swivel thrust bearing coupled with thrust bearing assembled in tandem way.

...more

Twin Screw

ETS Series Twin Screw Extruder Gear Box is developed by featuring high torque and high speed output rate. The gearboxes are embedded with excellence high dissipation and oil lubrication system to provide stable output under heavy loading force. The axial thrust is supported by axial roller-type swivel thrust bearing coupled with thrust bearing assembled in tandem way.

...more

Truck Loader

PEL Group Company of ELECON manufactures Different models of truck loaders up to a maximum capacity of handling 3000 bags per hour each of 50 Kgs. can be supplied for loading, stacking and lining up bags onto trucks. Wagon Loaders in different models upto 3000 bags per hour are also available. The loading jib is telescopic with 180° rotation and can be lifted by a mechanical or hydraulic jack.

...more

Stacker Reclaimer

For continuous stacking an reclaiming of crushed bulk materials, economics solutions can only be achieved by the use of combined bucket wheel stacker reclaimer. Elecon bucket wheel stacker reclaimermachine can stack the material to form the stockpile or reclaim the stockpiled material and feed onto themain line conveyor.

...more

Slew Drive

The planetary gear units normally have four-stage reductions out of which the first stage is designed as helical or bevel pair, and the remaining stages according to planetary gear systems.

...more

SIDE ARM CHARGERS

Side arm charger, widely used with Wagon Tippler as Wagon Marshalling equipment, helps in increasing the tippling speed of Wagon Tippler by Fast Placement and removal of Wagons from tippler table. SIDE ARM CHARGER For hauling rake of wagons, placement of wagons on tippler table and evacuation of empty wagons from tippler table.It is used in conjunction with shifter and ejector at outhaul side when there is limitation of track availibility. ELECON has supplied more then 250 Side Arm charger to various Clients.

...more

ship loaders

A Ship loader is used for loading bulk materials like clinker, Cement, iron ore, coal, fertilizers, etc. into ships for transportation by sea. Ship loaders are commonly used where bulk materials are exported from ports. ELELCON has supplied ship loader with capacity upto 1200 TPH

...more

Shiftable Conveyors

Shiftable conveyors, used at open-caste mines. Capable of handling materials at the rate of ranging from 6000 TPH to 20,000 TPH and is suitable for belt widths upto 2,400 mm. and up to 4.2 M/Sec belt speed .

Usage : Conveyors

...more

Roll Crusher

Soft to medium hard material crushing. Minimum Fine Generation.Lesser Power Consumption.Compact Design.Maintenance Friendly.Easy to replace parts.

...more

Ring granulator

Granular size product. Minimum Fine generation. Crushing efficiency up to 98%. Low Power Consumption. Unique ring design hammers (Toothed Plain). Tramp iron pockets to collect iron particles

...more

Reversible Hammer Crusher

Application Secondary crushing by impact action. Features Bi direction Construction. Fine Crushing. Open bottom discharge can Handle. Material with high moisture. Max. life of crusher internal parts Hammer and grinding path are of high chrome steel

...more

Rail Pusher Car

Pusher Car, also known as miniature locomotive, pushes wagon in or out of tippler. It consists of Drive Unit and body. After leading wagon is decoupled manually from the rake, remaining wagons are pulled back by the pusher car at predetermined wagon waiting position. Meanwhile, the tippler tips the loaded wagon and come back to the original position with empty wagon. Now, pusher car pushes the rake of remaining wagon to the tippler table, pushing out empty wagon. Thus, the cycle goes on till all wagons are tipped.

...more

Pulleys

Conveyor pulleys been recognized as a critical component of conveyor, failure of which could lead to extensive damage and down time. Hence special attention has been given to design an develop the most dependable pulleys. we manufacture pulleys for conveyors of belt width ranging from 400 mm to 2400 mm. for capacities upto 24,000 TPH Available in rubber lagging and ceramic lagging.

...more

Planetary Gearbox

The gear unit represents an almost integral component of the mill. The output flange of the gear unit is rigidly connected with the grinding table. In addition to transmitting the torque ,the gear unit also has capability to take up the reaction forces from the the griding force of the mil’s rollers.

...more

Pipe Conveyor

A pipe conveyor is a rubberized belt which is formed from a conventional troughed shape into a pipe, or tubular shape. Pipe conveyor technology has come far in the last 40 years or so and presently is on par with trough conveyor technology. As such, these conveyors can be compared. The choice of conveyor for any application should be weighed up against the specific criteria and objectives of each customer andor site.

...moreBe first to Rate

Rate ThisOpening Hours