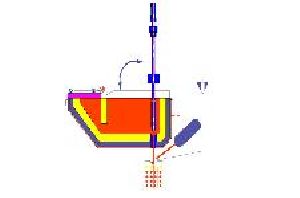

zinc pot

Ceramic Lined Zinc Pot along with Channel Inductors for coating and melting of Zinc on industrial strip, Pot can be equipped with single inductor upto 650 Kw or multiple inductors for total power of 4000 Kw, An advanced microprocessor based control to ensure operation at unity power factor, Automatic operation with temperature control maintain bath at desirable coating temperature within close tolerance, Each inductor with its own dedicated separate power supply, Forced air cooled W type inductor with SS Copper earth shield upto 500 kw, Water cooled inductor for upto 700 KW rating, Advanced High flow configuration of metal loop ensures less clogging on metal loop and offers better heat transfer as well as eliminates hot spot.

...more

Unheated pouring systems

Unheated pouring device – An excellent dosing and metering tool, for feeding to high pressure moulding line specially for SG and Ductile iron. Hydraulic movement in the direction of the mould line as well as perpendicular so that the poring nozzle may smoothly align with the spruce cup location suitable for both flask and flask less moulding line. An optional Nozzle Cleaning Device.

...more

Preheating Furnace

Die preheating furnaces are for pre heating of extrusion dies with very close temperature tolerances,Single or double draw out trolleys with vertical opening doors,The furnaces can be operated semi automatically, controlled by PLC systems with HMI that allow precise control of the process,The heater battery is designed with low watt density heaters, for long, trouble free life and are modular, making them easy to maintain,

...more

Pot Furnaces

Standalone pit type furnaces are designed for heat treatment of cast iron components. These furnaces are useful for auto ancillary units.The furnaces have high efficiency air circulation fans on the top of the furnace and housed in a top opening door. The door is either sliding or lift and swivel type.Concentric air passage houses heating elements in wire coil form or sinusoidal strip form.The heating elements are designed for low watt density for long life.High capacity fans provide high number of air passes ensuring rapid heat transfer to the charge and keeping heating elements in black zone.

...more

Pit Type Furnace

Standalone pit type furnaces are designed for heat treatment of cast iron components. These furnaces are useful for auto ancillary units.The furnaces have high efficiency air circulation fans on the top of the furnace and housed in a top opening door. The door is either sliding or lift and swivel type.Concentric air passage houses heating elements in wire coil form or sinusoidal strip form.The heating elements are designed for low watt density for long life.High capacity fans provide high number of air passes ensuring rapid heat transfer to the charge and keeping heating elements in black zone.

...more

Mains frequency coreless induction furnaces

An excellent tool for melting Cast Iron, S.G. Iron, Malleable Iron, etc. Operation at lower frequency yields vigorous and uniform bath movement for ease in alloy addition as well as homogeneity of melt. Robust, sturdy with steel frame furnace construction designed for harsh foundry operation. Optional features like exhaust hood, quick lining removal, load cell, pit guard system, etc. Micro processor based controlled air cooled tap changer power supply with contactor switching. Operation at unity power factor at all loads. No harmonics generation due to furnace operation. Conventional long coil ensures same temperature gradient throughout the length of lining. Quick lining removal facility as an option.

Power : 100 Kw to 10000 Kw

...more

Induction furnaces for pressurized pouring

Pressurized Pouring furnace with channel inductor for feeding metal to high pressure moulding line. Stopper rod mechanism with micro -processor based control for exact dosing of metal and swing-out construction for ease in replacement. Efficient “teach in” pouring control provides ease in control of poring weight. Optional laser control facility. An Optional nozzle cleaning device. Hydraulic movement in the direction of the mould line as well as perpendicular so that the poring nozzle may smoothly align with the sprue cup location suitable for both flask and flask less moulding line.

Power : 125 Kw to 1250 kw

...more

Copper Melting Furnace

Pressurized Pouring furnace with channel inductor for feeding metal to high pressure moulding line, Stopper rod mechanism with micro -processor based control for exact dosing of metal and swing-out construction for ease in replacement. Efficient “teach in” pouring control provides ease in control of poring weight. Optional laser control facilty, An Optional nozzle cleaning device, as well as perpendicular so that the poring nozzle may smoothly align with the sprue cup location suitable for both flask and flask less moulding line.

Power : 125 Kw to 1250 kw

...more

CONTINUOUS HEAT TREATMENT FURNACES

Ageing furnaces are for ageing of aluminum extrusions, Conductors, aluminum casting, etc. with very close temperature tolerances, Single or double draw out trolleys with vertical opening doors, The furnaces can be operated semi automatically, controlled by PLC systems with HMI that allow precise control of the process, The heater battery is designed with low watt density heaters, for long, trouble free life and are modular, making them easy to maintain, Contactor type or thyristorised power supply for maximum efficiency and higher temperature accuracy.

...more

brass induction melting furnace

Ensures melting of DRY WET BRASS chips at optimum metal loss without manual labour, Specific crucible configuration for BALD HEAD melting,Better Stirring effect in melt to produce dross free surface at center, Bald head melting ensures easy sinking of chips in melt while charging on a dross free surface, Special shape of the crucible along with Ceramic lined exhaust hood, Easy Access for dross remova, Automatic chips charging system as an optional.

Power : 300 Kw to 10000 Kw

...more

billet heater

Easy to heat variety of billet length without changing any taps, etc.Mains supply frequency Power supply generates higher depth of penetration in billet to yield better temperature uniformity (axially as well as radially).Robust and sturdy heater construction designed for harsh operation.Equipped with cold and hot billet handling system like cold billet elevator, pusher, motorized roller type hot billet discharge, counter holder, etc.

Power : 175 Kw to 1500 Kw

...more

ageing furnace

Ageing furnaces are for ageing of aluminum extrusions, Conductors, aluminum casting, etc. with very close temperature tolerances,Single or double draw out trolleys with vertical opening doors,The furnaces can be operated semi automatically, controlled by PLC systems with HMI that allow precise control of the process.

...more

Pot Furnace

Channel Type Induction Furnace

Cremation Furnace

Shaker Hearth Furnace

Drop Bottom Furnace

Zinc Galvanizing Furnace

melting cum holding furnace

Stress Relieving Furnace

Retort Furnace

Die Preheating Furnace

Be first to Rate

Rate This