Vibrating Screen

Circular Motion inclined Vibrating Screen is a two bearing free floating Vibrating Screen which efficiently screens all moderately free flowing materials. The circular throw action is derived from imbalance weights which are attached to the ends of the vibrator unit and transmit a uniform vibration to all screening surfaces and ensures that material travels over the screening surfaces at a constant rate. The amplitude or degree of vibration can be adjusted to suit a change of duty by adding or subtracting balance weight plates. Circular motion ensures rapid stratification at the feed end and produces an accurately size product in the shortest possible time. Screen's inclination normally varies between 15° to 25°. Speed of screen varies between 850 R.P.M. to 1150 R.P.M. depending upon the "G" Value desired. Screens are manufactured in following widths : 800, 1000, 1200, 1500, 1800, 2000, 2200 m.m. and lengths varying from 1500 m.m. to 7000 m.m. Number of decks, can be up-to four. Vibrator Unit : The Vibrator Unit is a steel shaft, completely housed in a protective steel tubular casing. Balance Weights are keyed to shaft. The bearings are specially designed for the use on screens and are a high capacity self aligning double roller type. These bearings have special tolerances and improved lubrication facilities to give extended bearing life under ardous working conditions. Labyrinth type grease sealings are provided to prevent dust getting into bearings. Supporting Coil Springs: Helical compression springs support the vibrating basket of the Vibrating Screen. They absorb all the working loads, without transmitting undesirable vibration to the supporting structure. Side Stretching Device: It is essential to keep the screen deck always in tension. For maintaining correct tension, side stretching arrangement is provided for the screen cloth. Selection of Screening Machine: Proper selection of screen size is very important. The size and type of screening machine to be used requires a very close scrutiny of the material to be screened, its screen analysis, moisture content, shape of particles, separation required etc. Special Features of Vibrating Screens : High specific screening capacity. Compact Design. Bolted construction. Easy interchangeability of screen cloths. Long working life. Tailor made to customer's needs.

...more

Stone Coal Crusher

With 20 years’ wide experience in the field. We have been able to put ourselves before you as a leading manufacturer of stone/coal crushers with various sizes and capacities. As per ISI. Efficient and dependable. Fitted with 4 nos. self alignment taper roller bearings. Cast steel head stock & c-40 shaft C.I. casting for heavy duty fly wheel M.S. fabricated body duly stressed relieved. High chrome manganese jaws for long life operation in single toggle design. We also undertake turnkey projects cement industries. Cattle feed plants, paper mill, fertilizer plants, for material handling equipments like belt conveyors, screw conveyors, bucket elevators chain and belt feeder etc.

...more

Single Toggle Jaw Crusher

Rullitech offers a wide range of sizes of Primary and Secondary Jaw Crushers that incorporate steeply aligned toggle seats for effective nip angles and high production ratios. Features and Observations Stress relieved frame large diameter Eccentric Shaft Self aligning Bearings Machined Jaw Locations Reversible Manganese steel jaws Grease purged Labyrinth bearing seals Toggle requires no lubrication Deep Crushing Chambers Large Balanced Fly Wheels

...more

Reversible Impactor

The Reversible impactor is a highly versatile crusher. It is a open bottom type machine. It can be employed for crushing of hard coal and lignite in power plants, coking coal for the iron and steel industry, limestone and gypsum as well as other related minerals of soft to medium-hard consistency. Unlike hammer mills, reversible impactors have no cage bars, but crush by impact only. They have few parts to maintain or replace, and require relatively little power to operate. Operations : As the material enters the reversible impactor, it is struck by massive steel hammers which cause it to fracture along its natural fault lines into smaller pieces. The material now moves at high velocity imparted by the swinging hammers. These pieces strike the stationary breaker blocks, resulting in further size reduction. The particles then rebound into the path of the hammers, repeating the reduction cycle, until the sized material exits through the open bottom of the crusher. This method of reduction produces a cubical product at high reduction ratios of up to 35 to 1, depending on the friability of the feed material. Over crushing and excessive production of fines are prevented because the bottom of the crusher is completely open, with no screen gratings to impede the flow of material. In addition, power requirements are less than that required by grate-type hammer mill and ring granulators for producing the same nominal output. Finally, when processing high moisture materials, this crusher reduces the chance of plugging. Advantages of Reversibility : With the ability of the rotor assembly to be rotated in either direction, the operator gains important advantages : Both hammer faces wear evenly. Breaker blocks on either side of the crushing chamber provide twice the wear area as compared to single direction crushers. Improved crushing performance as the hammers maintain a sharper profile, imparing a solid, direct impact to the incoming material. In a single direction crusher, hammers develop a rounded profile that delivers only a glancing blow to the material, resulting in lowered capacity and increased power draw. There is no need to pull the crusher out of service to manually turn the hammers.

...more

Horizontal Shaft Impactor

Rullitech Impactors are used as primary and secondary crushers for size reduction of various materials like limestones, Basalt, Blast furnace slag, coal, dolomite, gravel, concrete, asphalt etc., in wet and dry applications. These Crushers offer operators a very high ratio of reduction and can accept larger feed sizes. There are no screens at the discharge opening, thus avoiding plugging. Rullitech Impactors are specially designed to ensure reliability along with easy maintanance, interchangeable wear parts and fast replacement. These crushers require less capital outlay and produce higher percentage of cubical shaped products than competitive type crushers. Operation : Feed enters the primary crushing chamber and meets the blow bars, which impel the feed against the front breaker plate assembly. This action and the collision of material sufficiently reduced in the primary chamber passes by the front breaker plate assembly and enters the secondary chamber for final reduction. Feed Opening : Rullitech Impactors features a very large feed opening. Which enables optimum utilization of the impact chamber, with high capacity rates and excellent size reduction ratios. In, addition, plugging of the material is avoided. Blow Bars : The blow bars are reversible, enabling logner life and less stock keeping. Breaker Plate Assembly: The Breaker plate assembly can be optimally adjusted for particular applications. The breaker plate reaches till below the last crushing element of blow bar. The breaker plates are made of welded steel and are mounted with replaceable blow bars. Rotor : The rotor is mounted on a large diameter forged shaft, which is supported by over-sized, self-aligning, roller bearings located in heavy-duty split bearing housings. The blow bars of the rotor are held in the rotor by a simple locking device. The complete rotor assebly is hard-surfaced in critical areas and thermal stress relieved. Housing : The housing is fabricated with heavy ribs. It is also hinged and has big inspection doors for ease in maintanance. Drive : The Impactor is driven by V-Belts and Electric Motor. Key Features of Horizontal Shaft Impactor: Heavy Duty solid rotor construction. Two, three and four row configurations. Greased oversized bearings. Blow bars available in manganese and various compositions of chrome steels. High Reduction ratios to 30:1. High throughput capacity. Cubical product with high crush count. Selective crushing by speed and breaker plates adjustment. Interchangeable wear parts. Maximum operating reliability. Ease of Maintanance and service.

...more

Double Toggle Jaw Crusher

Double Toggle Jaw Crushers have one jaw fixed, while the other pivots about a top hinge. This moving jaw is shaped to move firmly and squarely against the material. There is no rubbing or grinding. Only compression, which produces a generally cubical product with minimum fines. The moving jaw is very well balanced, so 95% of the drive motor power is ued for crushing. While only 5% of the power is needed to move the jaw itself. As a result of this high mechanical efficiency, double Toggle Jaw Crushers require smaller size motors, keeping power costs down. Behind the stationary jaw are shims, used to adjust the distance between the lower ends of the jaws (closed side setting). The setting determines the output product size. There is also an arrangement of safety arm for protection from us-crushables accidental overloads.

...more

Coal Crusher

Fitted with 4 nos. self alignment taper roller bearings. Cast steel head stock & c-40 shaft C.I. casting for heavy duty fly wheel M.S. fabricated body duly stressed relieved. High chrome manganese jaws for long life operation in single toggle design.

...more

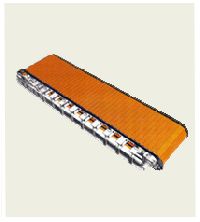

Apron Feeder

Rullitech apron feeders are custom designed for each application. They are of heavy duty construction suited for rugged conditions encountered in the mining and quarrying industries. They come with large diameter headshaft and tailshaft. Head and tail shaft roller bearings are sealed to prevent dust intrusion. The chains are crawler tractor type and are closely spaced to withstand shock loading of large lumps from the hopper. The steel flights are ribbed and overlapping and made of Manganese steel.

...moreBe first to Rate

Rate ThisOpening Hours