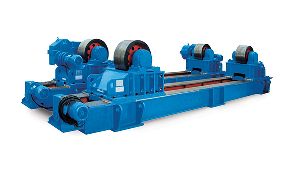

10MT Conventional Welding Rotator

310,000 - 350,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Traversing Rotators

Get Price Quote

AMIN’s Traversing Rotators (Conventional / Self Aligning) follow the well established reputation of their static counter-parts for ease of use and reliability. We are providing an economical and practical platform for all cylindrical vessel rotating problems. The Traversing Rotator ranges are all bogie mounted to carry vessels of various lengths, and to allow for traversing, in addition to rotation at the work site. Traversing Rotators are built to the highest standards with quality materials and components : - Robust, all-steel construction- Inverter controlled traversing and rotation at welding speeds.- All rollers of the Drive Section positively driven. Whatever your requirement – large or small, short or long – you will find that AMIN has the solution in Stationary or Traversing Rotators.

Best Deals from Welding Rotator

Welding Rotator

Get Price Quote

The Conventional Rotator is designed to aid the welding of cylindrical vessels. By using independent drive and idler units, vessels of varying lengths can be placed on the rotators supported on the rotator wheels. The wheels can be adjusted on the base frame to accommodate different vessel diameters. There is two type of rotator available one is conventional and another is self alignment. In self alignment wheel takes it’s own position as per diameter of components. So, no need to adjust manually. We can supply base mount, trolley mount and as per need of customer.

Welding Rotator

Get Price Quote

The Conventional Rotator is designed to aid the welding of cylindrical vessels. By using independent drive and idler units, vessels of varying lengths can be placed on the rotators supported on the rotator wheels. The wheels can be adjusted on the base frame to accommodate different vessel diameters. There is two type of rotator available one is conventional and another is self alignment. In self alignment wheel takes it’s own position as per diameter of components. So, no need to adjust manually. We can supply base mount, trolley mount and as per need of customer.

Self Aligning Rotator

Get Price Quote

The design of the AMIN Self - aligning Rotators incorporates many hidden features, which are unknown to our competitors.With the AMIN Self-aligning construction the trunnion brackets which support the rubber typed wheels automatically align themselves when changing from one diameter to another, no manual adjustment whatsoever is required.Each section supports the vessel on four points ensuring better traction, and on machines of 3 T to 500 T capacity and upwards all four wheels of the drive section are positively driven. This four point suspension is an added advantage when on handling thin walled vessels.The two top leading wheels of the drive section incorporate clutches which are loosened prior to loading the vessel and the top wheels can rotate freely when the vessel is loaded; thus regardless of weight if the vessel is lowered centrally between the frames, or firstly on to one wheel only, no damage can be sustained by the transmission.One problem in the welding of large diameter heavy vessels is the lining up of the strakes. To facilitate this problem of lining up, the AMIN Self-Aligning Rotators can be supplied with an arrangement whereby the trunnion brackets which support the rubber typed wheels can be moved across the frame by lead screw so that the vessel can raised or lowered by widening the trunnion centers or bring them closer together and in addition a secondary screw adjustment can be provided to move both the trunnion brackets either side of the center line approximately 38 mm. In order to ensure that the four wheel point support can be maintained over an extended range of diameters the SAR. Frames can be supplied so that a spacer can be inserted in the main frame between the trunnion centres so that they are capable of handling vessels upto 11 metres or more in diameter.

Welding Rotator

Get Price Quote

Welding Rotator, EOT Cranes, Welding Column

welding conventional rotators

Get Price Quote

welding conventional rotators, Welding Equipment, Welding Positioners

Self Aligning Rotator

Get Price Quote

Self Aligning Rotator