Water Cooled Chiller

200,000 Per Piece

1 Set (MOQ)

Material : Stainless Steel

Weight : As Per Designed

Voltage : 220V

Warranty : 1 Year

...more

U Tube Heat Exchanger

100,000 Per Piece

1 Piece (MOQ)

U Tube bundle Heat Exchanger can build "U" tube bundles, straight tube "floating" tube bundles, or we can retube fixed tubesheet heat exchangers when the bundles is not removable and multitherm is not locked into any one material. Heat-exchanger system consisting of a bundle of U tubes hairpin tubes surrounded by a shell outer vessel, one fluid flows through the tubes, and the other fluid flows through the shell, around tubes.Multitherm can duplicate any existing bundle to include dimensions, materials and performance.Some bundles tend to be build with copper tubes and steel tubesheets. U Tube bundle Heat Exchanger of each tube are connected to plenums (sometimes called water boxes) through holes in tubesheets. The tubes may be straight or bent in the shape of a U, called U-tubes. Specifications : U Tube bundle Heat Exchanger which typically have U-tubes. U Tube bundle Heat Exchanger can be used to boil water recycled from a surface condenser into steam to drive a turbine to produce power. Most U Tube bundle Heat Exchanger are either 1, 2, or 4 pass designs on the tube side. This refers to the number of times the fluid in the tubes passes through the fluid in the shell. Applications : U Tube bundle Heat Exchanger fluid goes in one end of each tube and out the other.Surface condensers in power plants are often 1-pass straight-tube heat exchangers see Surface condenser for diagram. U Tube bundle Heat Exchanger are two and four pass designs are common because the fluid can enter and exit on the same side. U Tube bundle Heat Exchanger construction much simpler. U Tube bundle Heat Exchanger are often baffles directing flow through the shell side so the fluid does not take a short cut through the shell side leaving ineffective low flow volumes. U Tube bundle Heat Exchanger are generally attached to the tube bundle rather than the shell in order that the bundle is still removable for maintenance. Counter current heat exchangers are most efficient and they allow the highest log mean temperature difference between the hot and cold streams. U Tube bundle Heat Exchanger companies however do not use single pass heat exchangers and they can break easily in addition to being more expensive to build. Often multiple heat exchangers can be used to simulate the counter current flow of a single large exchanger. Advantages : The simple design of a shell & tube heat exchanger makes it ideal cooling solution for a wide variety of applications. One of the most common applications is the cooling of Hydraulic Fluid and oil in engines, transmissions and hydraulic power packs. With right choice of materials they can also be used to cool or heat other mediums, Particularly with models where a floating tube bundle (where the tube plates are not welded to the outer shell) is available. Can also be used on fixed tube sheet heat exchangers.

Type : Automatic

Material : Stainless Steel

Color : Sliver

Voltage : 220V

Warranty : 1 Year

Shape : Cylindrical

Weight : As Per Designed

...more

Tube in Tube Heat Exchanger

100,000 Per Piece

1 Piece (MOQ)

Tube in Tube Heat Exchangers Our range of Corrugated Tube Heat Exchangers use corrugated Tubes to enhance heat transfer. Two types of heat exchanger are available. The mono-tube design has a single tube within a tube and the multi-tube design has a number of tubes inside a shell. Each design has variants for either industrial or hygienic applications. The construction can be either all welded or with removable tubes for ease of maintenance. Advantages: Higher thermal efficiency due to corrugated tubes Easy to clean Low maintenance Materials: Product side in AISI 316, AISI 316L, Duplex steels Service side in AISI 304 Other materials available on request Options: Stainless steel frame Thermal insulation

Type : Tube in Tube

Material : Stainless Steel

Certification : International Standard

Color : Sliver

Voltage : 220V

Warranty : 1 Year

Shape : Cylindrical

Weight : As per designed

...more

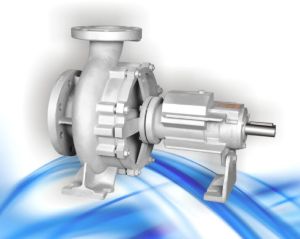

Thermic Fluid Pumps

540,000 Per Piece

1 Piece (MOQ)

THERMIC FLUID HOT OIL PUMP (Air Cooled, Single Stage, Horizontal, End Suction Pump) We are world’s largest manufacturer of thermal fluid pumps used to move heat-transfer oils at high temperatures. Our thermic fluid pump is also referred to as a hot oil circulating pump. It is the finest option for better leakage control and energy savings. Our thermic fluid pump has been designed to circulate hot oil and high-temperature liquid, which makes this pump more suitable for applications in heat transfer plants. The air-cooled pump designed by FITZER represents the highest quality and most effective air-cooled industrial pump in the market. FITZER is India's leading exporter of industrial pumps, exporting a wide range of top-quality products to industries worldwide. We export our products to Turkey, Saudi Arabia, Dubai, Thailand, Australia, Sri Lanka, Bangladesh, Oman, South Africa, Iraq, and many other countries. TECHNICAL SPECIFICATIONS: Operating Range: Capacity: up to 1100 m3/hr Head: up to 150 Meter Pressure: up to 15 kg/cm2 Size: 32 mm to 125 mm Speed: up to 3500 rpm Temp: up to 350 C M.O.C.: Grey Cast Iron, Cast Steel, Alloy Cast Steel, S.S 304, S.S 316, etc. PUMP FLANGES Discharge Flanges: DIN 2533 – PN 16 Suction Flanges: DIN 2533 – PN 16 DESIGN FEATURES: Main dimensions according to DIN 24256 (ISO 2858) Single-stage, end suction, centrifugal volute pump. Bearing housing is made of spherical cast iron and mounted to the casing keeping minimum heat transfer from the casing to the bearing housing. On the bearing housing, there are fins for natural convection. There is a thermal-resistant soft packing seal behind the impeller. It slows down the leakage and prevents the pumping to be stopped if there is mechanical seal damage. First bearing is on the impeller side and lubricated with a working medium. Second bearing is on the coupling side and lubricated with grease. The shaft is designed according to the minimum heat transfer criteria. The mechanical seal stands between two roller bearings and is close to the roller bearing on the coupling side. This gives the mechanical seal a longer working life since it is in a low-temperature region.

Condition : New

Automatic Grade : Semi Automatic

Power : 10hp, 1hp, 2hp, 3hp, 5hp, 7hp

Pressure : High Pressure, Low Pressure, Medium Pressure

Application : Industrial Use

Certification : CE Certified, ISO 9001:2015

Type : Thermic Fluid Pumps, THERMIC FLUID HOT OIL PUMP,THERMIC FLUID HOT OIL PUMP

Weight : 10-20kg, 20-300kg, 30-40kg, 40-50kg

Warranty : ONE YEAR

Country of Origin : India

Brand : FITZER

...more

Thermal Fluid Heater

50,000 Per Piece

1 Piece (MOQ)

A thermic fluid heating system generally used in a system where the pressure is not desired in a process and temperature requirement is higher and using the boiler for high-temperature services may increase the cost of a project. Thermal Fluid Heaters can improve process consistency and reduce downtime leading to a further increase in profitability. Industrial Applications of Thermic Fluid Heaters Thermic fluid systems can be used to generate heat in various process industries, such as:- Food processing industries Rubber and plastics industries Publishing and print industries Metal fabrication and finishing plants Paper industries Textile industries Natural gas processing plants Crude oil extraction and processing industries. Chemical Industries Plywood and Laminates Confectionery Advantages of Thermic Fluid Heaters High Capacity Heating System Fully automatic unit – Maintains the desired temperature of the thermic fluid High System Efficiency – Reduced operating cost. Best applicable for High-Temperature Heating Can attain temperatures upto 300 o C Minimum site work and ease of installation Can operate on the variety of fuels as per local availability Failsafe design and dependable safety instruments Rugged design and superior construction High flow rate ensures the higher life of thermic fluid and heater coil Backed by prompt and efficient after sales service Deaerator/Expansion Tank Integral Arrangement type

Type : Automatic

Material : Alloy Steel, Mild Steel

Certification : 9386548

Application : Industrial

Weight : As Per Designed

Power Source : Thermal Power

Voltage : 440 V

...more

Thermal Energy Storage System

5,000,000 Per set

1 Set (MOQ)

Thermal Energy Storage System (CWTES). This system utilizes only the sensible heat of water for cooling energy storage in a chilled water storage tank and discharges the stored coldness for air-conditioning during the on-peak time. The key technology of CWStorage system is the diffuser design which ensures thermal stratification of chilled water and warm water by density difference. FTEnE’s technology is the state of the art technology which is recommended in ASHRAE’s design guide. They have a long history of installation around the world including U.S.A., Japan, Korea and middle-east Asia. Some key features of Chilled Water-Thermal Energy Storage Cooling: Lowest initial investment cost 30-40% energy saving by utilizing conventional chillers whose Efficiency is higher than low temperature chillers Simple system with easy controls without additional heat Light in weight compared to Si-Br. Exchangers and less equipment Efficiency of discharging coldness is very high Easy to convert conventional system into CWTES system by Adding only chilled water storage tank Convertible to heating purposes Environmentally friendly system free from brine Storage water can be utilized for fire-fighting in emergency

Type : Stratified Chilled Water Type

Color : Grey

...more

super heater

100,000 Per Piece

1 Piece (MOQ)

A SUPER HEATER is a device used to convert saturated steam or wet steam into super-heated steam or dry steam. There are three types of super heaters : 1. RADIANT SUPER HEATER : Placed directly in the combustion chamber. 2. CONVECTIVE SUPER HEATER : Located in the path of the hot gases. 3. SEPARATELY FIRED SUPER HEATER : Totally separated from the boiler. We at SGM TECH design and manufacture all types of super heaters. We study the client's requirements and design the most optimum solution by adopting best engineering methods.

Type : Super

Material : Cast Iron, Iron, Steel

Certification : CE Certified

Application : Industrial

Voltage : 440V

Power : 3-6kw

Power Source : Electric

Warranty : 1 Year

...more

Studded Fin Tube

5,000 Per Meter

10 Piece (MOQ)

the studded fin tube is manufactured by resistance welding of studs on the bare tubes. the fins are manufactured by welding of the fin material which is essential a stud or rod welded at base to the tube by electrical resistance process. the current is made to flow through the tube and the base of the studs. the studs are specifically made in shapes to facilitate the welding process. the stud; during the finning “welding” process is also mechanically pressed on the tube at the point of welding thence causing a very good mechanical bond. this type of fin tube find very good application in high pressure and high temperature applications. the mechanical bond is very strong and hence finds application in places where extreme mechanical load, stress is expected while during the process or cleaning etc. these fin tubes find application in finned pipes, air coolers, and heat exchangers etc and are preferred in industries like petrochemical refineries, power plants, chemical industries, and steel plants etc. manufacturing range (studded fin tube ):- sr. no particulars range 1 base tube material stainless steel, carbon steel, alloy steel, titanium , copper, duplex stainless steel, & inconel etc. (all material in the theoretical limit) 2 base tube outside diameter 60 mm to 200 mm 3 base tube thickness 3 mm to 12.70mm above 4 base tube length 2000 mm min to 15000 mm 5 stud material carbon steel/stainless steel/alloy steel 6 stud thickness 6mm to 16mm 7 stud density 15.88mm or 63 studs per plate per meter (can be customized to clients requirements) 8 stud height 12.7mm to 63.5mm 9 bare ends as per client requirement we can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. we use only prime quality base tube and fin stud material. the stud fin tubes/stud fin pipes can be supplied with en 10204 en 3.1 and en 3.2 certifications. we can provide third party inspection from any reputed inspection agency.

Brand Name : FITZER,FITZER

Material : Copper, Iron, Metal, Stainless Steel, Stainless Steel, Carbon Steel, Alloy Steel, Titanium , Copper, Duplex Stainless Steel, & Inconel etc

Finishing : Galvanized

Surface Finishing : Polished

Color : Grey, Metallic

Condition : New

Application : Condenser, Cooler, Heater, Vaporizer

Size : 60 mm to 200 mm

Certification : ISO 9001:2015

Grade : ASME

Feature : Rust Resistance, High Efficiency

Technics : MANUFACTURING STANDARDS

Outer Diameter : STUD HEIGHT: 12.7mm to 63.5mm

Type : STUDDED FINNED TUBES,Studded Finned Tubes

Diameter : 0-10mm, 10-20mm, 20-30mm, 30-40mm, 40-50mm, 50-60mm, 60-70mm, 70-80mm, 60 mm to 200 mm

Thickness : 3 mm to 12.70mm Above

Structure : AS PER REQUIREMENT

Warranty : ONE YEAR MANUFACTURING DEFECTS

After-Sales Service Provided : Yes

Country of Origin : India,India

Liquid Flow Rate : AS PER DESIGN

Matterial : Carbon Steel, Carbon Steel/Stainless Steel/Alloy Steel

Warranty : ONE YEAR MANUFACTURING DEFECTS

...more

Storage Tanks

100,000 Per Piece

1 Piece (MOQ)

Type : Fabricated

Material : Stainless Steel

Shape : Horizontal, Vertical

Application : Industrial

Color : Metallic

Surface Finishing : Coated

Weight : As per designed

...more

Stenter Machine Heat Exchanger

30,000 - 500,000 Per Piece

1 Piece (MOQ)

Essential part of Stenter machine widely used in Hot air stenter machine. Generally manufactured from MS & Aluminum material Duly hydraulically tested ready to fit, easy to replace with exsisting heat exchanger.

Country of Origin : India

Type : Stenter Machine Heat Exchanger

Certification : ISO 9001:2015

Weight : 100-1000kg

Condition : New

Driven Type : Mechanical

Warranty : 1year

Automation Grade : Manual

Color : Grey

Voltage : NA

Power : NA

Type : Stenter Heat Exchanger

Size : As per Requirement

Material : MS, SS, Aluminum, Buyer to specify

Country of Origin : India

Color : Grey, Industrial Grade

...more

Steam Boiler

100,000 Per Piece

1 Set (MOQ)

The Max Series are a range of packaged, three pass boilers designed to operate on various oil and gaseous fuels. Suitable for various industrial applications, this series is designed to respond quickly to the continuous and fluctuating workloads of various processes. Oil & Gas fired Steam Boiler Features Offered with high efficiency, monobloc or duo bloc burner.Burner designed for easy maintenance and adjustments.Oil heating and circulation system provided to accumulate excess fuel oil flow.Highly durable and cost-effective performance achieved.High purity steam generation reduces fuel costs.Air preheater, Economizer and other accessories can be added to increase efficiency and lower operating costs.

Type : Automatic

Material : Stainless Steel

Application : Liquid Boiling

Weight : As Per Designed

Voltage : 380V

Driven Type : Electric

Capacity : 1 TPH to 6 TPH standard design; Customized up to 36 TPH

...more

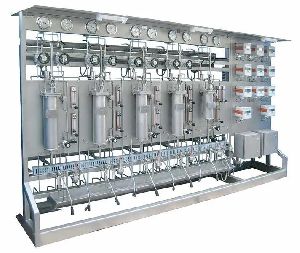

Steam And Water Analysis System (SWAS)

50,000 Per Sets

1 SET (MOQ)

The Steam/Water Analysis Systems (SWAS) are designed conform latest modern technology and has been continuously improved to keep the reability of your water steam analysis safe at all times and to protect your power plant from corrosion and scaling, suitable for power plant chemistry. Steam and Water Analysis System (SWAS) are designed for continuous monitoring and control of water and steam purity in the boiler plant cycle and at other important analysis points. The SWAS sampling system shall obtain samples from steam and water pipelines which shall be adequately conditioned and flow through water analysers for continuous analysis and provide parallel facility for grab sampling. The analyser outputs signals shall be used for continuous monitoring of various parameters like analysis of pH, Specific Conductivity, Cation Conductivity, Degassed Conductivity, Sodium, Silica, Dissolved Oxygen, Phosphate, Chlorides, TOC etc. The assembly of multiple instruments in a shelter creates several economic advantages: Reliable / stable measurement A good working environment for monitoring and maintenance Lower maintenance costs Longer lifespan of the equipment, etc. In a lot of cases a “walk-in” shelter is a very good and durable solution.

Country of Origin : India

Type : Power Plant Equipment

Certification : CE Certified, ISO 9001:2008

Application : Industrial, Oil, Gas Industry, Power Generation Plant

Weight : 10000-15000kg

Color : As per specification/Drawings

Voltage : 220V

Condition : New

Automatic Grade : Automatic, Fully Automatic

Driven Type : Electric, Mechanical

Warranty : 1year

Brand : FITZER

Material : SS316

Country of Origin : INDIA

Warranty : 1 Year

...more

Steam Accumulators

200,000 - 5,000,000 Per Piece

1 Sets (MOQ)

Steam Accumulator is a pressure tank made up of steel contain hot water and steam under pressure steam accumulator is a type of energy storage device. Accumulators are modern boilers are small in size, Efficient and high responsive change in loads. Steam accumulators is an extension of the energy storage capacity of boilers, steam boilers have a certain capacity for producing and supplying steam. For example: when the demand for steam from the plant is low and the boiler can generate more than required steam the excess steam is introduced into a mass of water stored under pressure. FUNCTION OF STEAM ACCUMULATOR Steam Accumulator is a pressure tank made up of steel contain hot water and steam under pressure steam accumulator is a type of energy storage device. Accumulators are Morden boilers are small in size, Efficient and high responsive change in loads. Excellent performance High operational frequency Quality tested Operated at optimum efficiency USES OF STEAM ACCUMULATOR Steam Accumulator is a pressure tank made up of steel contain hot water and steam under pressure steam accumulator is a type of energy storage device. Accumulators are modern boilers are small in size, Efficient and high responsive change in loads. Steam accumulators is an extension of the energy storage capacity of boilers, steam boilers have a certain capacity for producing and supplying steam. For example: when the demand for steam from the plant is low and the boiler can generate more than required steam the excess steam is introduced into a mass of water stored under pressure. DESIGNING SPECIFICATION FOR STEAM ACCUMULATOR Accumulator is constructed in the form of cylindrical, horizontal steel tank type of the tanks are based on the customer requirement and application. Data required for Steam Accumulators are as fallows Capacity Flow rate Temperature Charging pressure Discharging pressure

Driven Type : Mechanical, Pneumatic

Color : Grey, INDUSTRIAL GRADE

Condition : New

Power : As Per Plant Capacity

Automation Grade : Automatic, Manual, Semi Automatic

Application : Industrial Use, Steam Accumulator Is A Type Of Energy Storage Device

Certification : CE Certified, ISO 9001:2008, IBR APPROVED - NON IBR

Voltage : NA - STEAM STORAGE TANK

Type : Accumulator,STEAM ACCUMULATORS,STEAM ACCUMULATORS

Weight : AS PER CAPACITY

Warranty : 1year, 2years

Country of Origin : India,India

Brand : FITZER

...more

Stainless Steel Hoppers

10,000 - 50,000 Per piece

1 Piece (MOQ)

Stainless Steel Hopper Hopper is a container for a loose bulk material typically one that tapers downward and is able to discharge its contents at the bottom. We are specialized in the custom fabrication of Stainless Steel hopper for pharmaceutical, packaging and food-processing machinery components as per customer drawing, specification and need. We fabricate SS hopper using finer quality, physically and chemically lab tested material from well acknowledged manufactures and dealers. We inspect the quality of hopper at various stages of production and finally deliver the premium quality hopper to our customers.

Country of Origin : India

Type : SS Hopper

Certification : ISO 9001:2015

Weight : 10-20kg

Color : SS

Voltage : 110V

Condition : New

Automatic Grade : NA

Power : NA

Driven Type : NA

Warranty : 1year

Brand Name : FITZER

Application : Hopper

...more

Spiral Heat Exchanger

100,000 Per Piece

1 Piece (MOQ)

Design Features & Benefits The spiral plate heat exchanger is made by rolling two long metal plates around a center core to form two concentric spiral flow passages, one for each fluid. The plate edges are welded shut so that each fluid stays within its own passage and there is no flow bypassing or intermixing. Channel plate width and spacing (gap between plates) are optimized for the specified duty, maximum heat transfer, and ease of access. The plate gap is maintained by welded spacer studs although some designs do not require them. Due to its inherent circular design and large surface area to volume ratio, the spiral heat exchanger offers unique advantages over other types of heat exchangers like the shell and tube. High Thermal Efficiency Single and long curving flow passages with a uniform rectangular cross-section ensure superior flow distribution, intense turbulence, and high heat transfer coefficients (50-100% greater than shell & tubes). Self-Cleaning Passages The spiral's single-flow passages induce high shear rates that scrub away deposits as they form. This self-cleaning effect reduces fouling and makes spiral heat exchangers ideal for handling tough fluids such as process slurries, sludge, and media with suspended solids or fibers. Countercurrent or Co-current Spiral heat exchangers normally operate in true countercurrent flow for close approaches and temperature crosses. Occasionally a co-current flow design has major benefits, especially in cooling or heating fluids prone to gelation, burn-on, freezing or similar skin temperature related fouling. Small Footprint & Easy Access The spiral heat exchanger is compact and requires minimal space for installation and servicing. Removable covers provide easy access to interior heat transfer surfaces for field inspections, routine maintenance, or manual cleaning if required.

Brand Name : FITZER

Material : Stainless Steel

Finishing : Coated

Shape : Cylindrical

Color : GREEN, GREY, INDUSTRIAL GRADE EPOXY

Condition : New

Automatic Grade : Manual

Power : NOT APPLICABLE

Speciality : Reliable, Robust Construction, Easy To Use, High Efficiency, Counter Current And Co Current Flow

Medium used : WATER, SLURRY LIQUID

Usage : Water, Oil, Air, Heat Transfer, Hydraulic And Industrial Process, HIGH THERMAL EFFICIENCY

Size : As Per Specification/Drawings

Certification : ISO 9001:2008 Certified

Grade : ASME, API, TEMA, PED

Voltage : NOT APPLICABLE

Operating Temperature : -100 DEG C TO 500 DEG C

Packaging Type : Wooden Box

Hardness : METAL

Technique : Counter Current And Co Current Flow

Production Capacity : 5 Units Per Month

Dimension (LxWxH) : As Per Designed

Type : Spiral Heat Exchanger

Diameter : 300 MM & ABOVE

Thickness : 2MM TO 50 MM

Weight : As Per Designed

Phase : NOT APPLICABLE

Warranty : 1 Year

Country of Origin : India

Driven : BY PROCESS

Flow Rate : 5 LPM AND ABOVE

Maximum Working Pressure : 45 BAR & ABOVE

Corrosion Resistance : Yes

Depth : AS PER DESIGN

Ratings : -100 DEG C TO 500 DEG C

Outlet Temperature : AS REQUIRED

Inlet Temperature : -100 DEG C AND ABOVE

...more

Shell & Tube Heat Exchanger

100,000 Per Piece

1 Piece (MOQ)

We manufacture Shell & Tube type Heat Exchangers in a wide variety of sizes & materials. We have a complete facility to design (Thermal and Mechanical) and manufactures complete range of Shell and Tube Heat Exchangers for cooling, condensing and heating application. A Shell & Tube Heat Exchanger Consists of a Shell with Traditional plain tubes or enhanced surface tubes for high thermal performance. Our manufacturing facility is well supported by in house design facility equipped with latest software’s & design codes and welding development department to establish manufacturing process for any new material.

Country of Origin : India

Certification : ISO 9001:2008

Weight : As Per Designed

Color : Available In Many Colors

Voltage : 380V

Condition : New

Automatic Grade : Manual

Power : NA

Type : Fixed Tube Sheet, Removable tube Bundle, U-Tube, Coil in Tank, double Pipe

...more

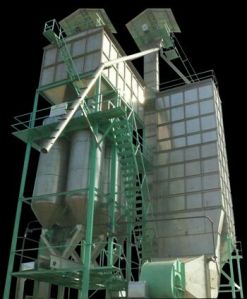

rice mill heat exchanger

50,000 Per piece

1 Piece (MOQ)

We are prominent manufacturers & suppliers of Rice mill Heat Exchangers from India. We are appreciated in the worldwide market and are offered at the competitive prices. We are able to maintain the trust and allegiance of our clients by constantly supplying products at par with international quality standards. Product Details: Application Food Process Industry, Power Generation, Hydraulic and Industrial Process, Mining & Construction Industry, Pharmaceutical industry Medium Used Oil, Water, Air Inlet Temperature as per requirement Type Air-Cooled Outlet Temperature as per requirement Flow Rate (L/min) as per requirement Maximum Working Pressure (in PSI) 300 psi Rice Mil Furthermore, the range is used in the following: Heat Recovery project. Paper manufacture industries. Printing industries. Wet processing machinery for textile industries. Plywood industries. Food processing Industries. Chemical & fertilizer industries.

Brand Name : FITZER,FITZER

Material : As Per Specification/Drawings,SS, MS, ALUMINUM, AS PER REQUIREMENT

Finishing : As Per Requirement

Shape : Rectangular

Color : Sliver

Condition : New

Automatic Grade : Semi Automatic

Power : NA

Speciality : Reliable, Robust Construction, Easy To Use, High Efficiency, HIGH THERMAL EFFICIENCY

Medium used : OIL, WATER, AIR

Usage : Air, Heat Transfer, Hydraulic And Industrial Process, Paper Manufacture Industries,Printing Industries. RICE MILLS,Food Process Industry,Power Generation,Mining & Construction Industry,Pharmaceutical Industry

Size : As Per Specification/Drawings,AS PER DESIGN/REQUIREMENT

Certification : ISO 9001:2015

Grade : ASTM

Voltage : NA

Operating Temperature : AS PER REQUIREMENT

Packaging Type : Wooden Box

Hardness : DURABLE

Technique : NA

Production Capacity : 50

Dimension (LxWxH) : AS PER REQUIREMENT

Type : RICE MILL HEAT EXCHANGER,RICE MILL HEAT EXCHANGER,AIR COOLED

Diameter : NA

Thickness : AS PER DESIGN

Weight : 500-1000 Kg, 1000-2000 Kg

Frequency : NA

Phase : NA

Warranty : 1 Year

Country of Origin : India

Driven : PROCESS & UTILITY

Maximum Working Pressure : 300 Psi

Corrosion Resistance : Yes

Depth : AS PER REQUIREMENT

Ratings : AS PER DESIGN/REQUIREMENT

...more

Pressure Vessels

100,000 Per Piece

1 Piece (MOQ)

Vessels & Tanks :- We Design, Engineering and manufacture customized Vessels and Tank with various material of construction line MS, SS 304, SS 316L, FRP coated or MS Rubber Lined, PTFE lined and many more. We are working with nos. of OEM for their routine requirement of vessels and tanks in their projects. Reactors:- Reactor Vessel is the heart of process of any industry. We offer customized design (process and mechanical) and do fabrication in our own workshop as per Good Engineering Practice as well as for ASME codes also. We deal in all types of reactor vessel like jacket, non jacketed , agitated and limped. We also deal in pillow plate jacket reactor vessel also which provided high heat transfer with low operating cost and capital cost too.

Type : Fabricated

Material : Aluminium, Mild Steel

Shape : Round

Color : Grey

Condition : New

Pressure : 15-30bar

Surface Finishing : Polished

Warranty : 1 Year

Weight : As per designed

...more

Pillow Type Plate Heat Exchanger

50,000 Per piece

1 piece (MOQ)

Pillow Type Plate Heat Exchanger uses metal plates to transmit heat between two fluids and is available in different specifications. Also, using this modern solution has more advantages over conventional heat exchangers. At FITZER, you will get the unparalleled quality at industry leading prices. Being one of the industry’s leading Plate Heat Exchanger Manufacturers in Gujarat - INDIA, We offer several specifications to choose from.Major Characteristics Of Plate Heat Exchanger Are: Simple And Compact Design: This Industrial Plate Heat Exchanger has a simple fabrication and comes in small and easy-to-use designs to fit in your industry premises. These thin sheets have corrugations and patterns to increase the surface area as well as the efficiency of the products. Quick To Clean And Maintain: These Heat Exchangers are made of good quality metal, which makes it easier to clean and maintain them after completing the application. Easy To Enhance The Capacity: You can simply expand the size and capacity of the sheet by just adding one along with others. Application Areas: Steel Industry Marine Industry Pharma Industry Dairy Industry Beverage Industry

Finishing : SAND BLAST

Type : Heavy Duty

Material : Metal

Usage : Industrial

Voltage : 220 V

Warranty : 1 Year

Weight : As Per Designed

Brand Name : FITZER

...more

Paddy Dryer Heat Exchanger

200,000 Per Piece

1 Piece (MOQ)

Leveraging on rich expertise and advanced manufacturing facility, we are counted as one of the reckoned manufacturers and exporters of Paddy Dryer Heat Exchanger. Quality is our prime focus, hence we source tested quality materials from authentic vendors to manufacture these heat exchangers as per industrial standards. Finds application in chemical, oil and refinery plants, our Paddy Dryer Heat Exchanger is demanded among our clients for its impeccable performance, easy installation and rust proof finish. Features of Paddy Dryer Heat Exchanger : Uniform and reliable heat transfer Rust proof body Hassle free installation

Weight : As Per Designed

Size : 500 MM

Color : Silver

Voltage : 230-415 Volt (v)

Application : Food Process Industry, Power Generation, Hydraulic and Industrial Process

...more

Milk Processing Plant

1,000,000 Per Set

1 Set (MOQ)

Our company is engaged in manufacturing and supplying high quality dairy milk processing plant that requires less maintenance and can be installed easily. It is used in the processing of milk and is fabricated using premium quality components and advanced technology inline with the defined industry standards. The offered machine is available in various technical specifications to meet the diverse needs of the clients. We offer this dairy milk processing plant at industry leading prices. Features: high strength sturdiness smooth operation high performance we offer milk processing plant with automation systems and services that range from 100lph to 1000lph. The provision of electronic process control up to integrated, complete with the corresponding management information systems. Only the latest industrial standards are used for all automation projects.in this respect batch processes are automated in accordance with an essential factor for a transparent, traceable production. To adapt existing production plants to new generations of automation systems (e.g. When replacing the visualization system or upgrading from s5 to s7) migration strategies will be developed for you that allow safe conversion while production continues to run.

Brand Name : FITZER,FITZER

Driven Type : Electric

Color : Grey, Silver

Condition : New

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Power : 1-3KW

Application : DAIRY MILK PROCESSING PLANT

Certification : CE Certified, ISO 9001:2008, FOOD GRADE

Voltage : 380V

Type : Milk Processing Plant, Mini Milk Processing Plant,MILK PROCESSING PLANT

Weight : AS PER CAPACITY

Warranty : 1year

After-Sales Service Provided : Yes

Country of Origin : India,INDIA

Warranty : ONE YEAR

...more

Marine Engine Oil Cooler

20,000 Per Piece

1 Piece (MOQ)

With engine efficiency constantly improving, the demand for more efficient oil cooling has never been greater. Bowman is a leading UK manufacturer of efficient, durable oil coolers for both industrial and marine engines and transmissions. Designed specifically for lubrication oil cooling, these high-quality units can be used with engines rated up to 8900 kW and are suitable for use with a range of cooling media, including sea water, fresh water or engine coolant. Product Benefits Compact design Easily installed and integrated with the engine Premium quality UK manufactured, using quality components Easy product selection Available quickly from our technical experts Rapid delivery Extensive stockholding for fast response Wide range Suitable for engines rated from 20 kW to 8900 kW High performance Models are available for up to 30 bar oil pressure

Type : Automatic

Material : Steel

Application : Industrial

Color : White

Size : Standard

...more

l fin tube, ll fin tube

5,000 Per Meter

10 Meter (MOQ)

The ‘L’ FIN TUBE, ‘LL’ FIN TUBE, ‘KLM’ FIN TUBE also known as Wrap Around Fin Tube. This type of Fin Tube widely finds acceptance where the Heat Transfer Temperature is relatively lower and the cost needs to be controlled. These type of Fin Tubes are relatively lesser in cost as compared to the ‘G’ Type Fin Tube and the Extruded Type Fin Tube. In ‘L’ Type Fin Tube or also known as ‘L’ Foot Fin Tube the finning is done by wrapping around the Fin stock spirally around the base tube. This is as reason also known as spirally wound Fin Tube. The base of the fin stock is Shaped in to and ‘L’ shape which gives a base for the fin to stand on firmly. Also the ‘L’ shape provides a certain protection against the atmospheric corrosion. The next version of wrap around Fin Tube and also of ‘L’ Fin Tube is ‘LL’ Fin Tube. The process is similar to the L Fin Tube type. However, the improvement is that the ‘L’ Foot of the previous fin is completely overlapped by the ‘L’ Foot of the next fin. This gives the Fin base a shape of tow ‘L’ foot simultaneously. It provides excellent corrosion resistance. The last and the most widely used type of wrap around Fin Tube is ‘KLM’ Fin Tube or ‘Knurled L’ Foot Fin Tube. This is currently one of the most widely type used and preferred Fin Tubes. This type of Fin Tube is manufactured similar to the ‘L’ Fin Tube. However, the process involves Knurling the Tube and at the same time the ‘L’ base of the fin stock to firm a frim bond and much better contact between the Fin and the Tube. In all the above type of wrap around Fin Tubes the fins are held by Spiral Tension, The ends are required to be firmly held to gather by means of Mechanical Bonding, Brazing etc. This tube also has an added benefit of using Much Lower Thickness of the Base tube thereby reducing the cost considerably. These Fin Tubes find application in AIR FIN COOLERS, RADIATORS etc. and are preferred in Industries like Power Plants, Chemical Industries, Petroleum Refineries, Chemical process Plants, and Rubber Plants etc. Manufacturing Range ‘L’ FIN TUBE, ‘LL’ FIN TUBE, ‘KLM’ FIN TUBE (WRAP AROUND FIN TUBE):- Sr. No Particulars Range 1 Base Tube Material Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, Inconel etc. (all material in the theoretical limit) 2 Base Tube Outside Diameter 12.70 mm to 38.10 mm 3 Base Tube Thickness 1.25mm And Above 4 Base Tube Length 500 mm Min To 15000 mm 5 Fin Material Aluminum, Copper, Stainless Steel, etc. 6 Fin Thickness 0.3mm, 0.35mm, 0.4mm, 0.45mm, 0.55mm, 0.60mm, 0.65mm 7 Fin Density 236 FPM (6 FPI) to 433 FPM (11 FPI) 8 Fin Height 9.8 mm to 16.00 mm 9 Bare Ends As per Client Requirement 10 Manufacturing Capacity 5,00,000 Meter Per Annum We can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. We use only Prime Quality base tube and Aluminum Material. The Extruded Fin Tubes can be supplied with EN 10204 EN 3.1 and EN 3.2 certifications. We can provide Third Party Inspection from any reputed inspection agency.

Brand Name : FITZER,FITZER

Material : Aluminium, Brass, Copper, Iron, Metal, Stainless Steel

Surface Finishing : Polished

Color : Grey, Metallic, Shiny Silver, Silver

Condition : New

Application : Air Cooled - Heat Exchangers

Size : 0-15mm, 15-30mm, 30-45mm, 45-60mm, 60-75mm, 75-90mm, 90-105mm, As per specification/Drawings

Certification : ISO 9001:2015

Grade : ASME, ASTM, IBR

Feature : Corrosion Resistance, High Quality, High Tensile, Accuracy Durable,Corrosion Resistance,Dimensional,High Quality,High Tensile,Non Breakable

Type : ‘L’ / ‘LL’ /’KL’ TYPE FIN TUBE,‘L’ / ‘LL’ /’KL’ TYPE FIN TUBE

Diameter : 0-10mm, 10-20mm, 20-30mm, 30-40mm, 40-50mm, 50-60mm, 60-70mm, 70-80mm, AS PER REQUIREMENT

Thickness : 0-5mm, 10-15mm, 5-10mm, As per Drawing/Specification

Country of Origin : India

...more

Low Integral Fin Tube

5,000 Per Meter

10 Piece (MOQ)

The ‘Low Fin Tube’ is also known as Integral Fin Tube. This type of fin tube is widely being used in the Industry Today. The Low Fin Tubes/Integral Fin Tubes are increasingly being used in various Fluid Heat Exchangers. Unlike other Fin Tubes the application is not limited to Air – Fluid type of heat exchangers. As a result they are used in various types of Shell And Tube heat exchanger also. The fins are manufactured rolling the Fin in the Base tube Itself. The fin height is relatively very low. However number of Fins Per inch or the fin Density can be increased greatly and improve the heat transfer area. The rolling is done on a special machine and the same can be supplied in straight as well as U bend configuration. These Fin Tubes find applications in the Oil Coolers , Shell and Tube Heat Exchanger etc. Manufacturing Range (Low Fin Tube/Integral Fin Tube):- Sr. No Particulars Range 1 Base Tube Material Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, and Inconel etc. (all material in the theoretical limit) 2 Base Tube Outside Diameter 12.70 mm to 38.10 mm 3 Base Tube Thickness 2.11 mm And Above 4 Base Tube Length 500 mm Min To 15000 mm 5 Fin Density Up to 1023 FPM (26 FPI) 6 Bare Ends As per Client Requirement 7 Manufacturing Capacity 7,00,000 Meter Per Annum We can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. We use only Prime Quality base tube and Aluminum Material. The Extruded fin Tubes can be supplied with EN 10204 EN 3.1 and EN 3.2 certifications. We can provide Third Party Inspection from any reputed inspection agency.

Size : 12.70 mm to 38.10 mm,12.70 mm to 38.10 mm

Brand Name : FITZER,FITZER

Material : Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, and Inconel,Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, and Inconel

Shape : As per Design

Application : Radiant Heating Dies and Manifolds. Immersion Heating. Solar. Textile Industry

Feature : Heat Transfer Efficiency:- Good

Taste : NA

Form : NA

Automatic Grade : NA

Packaging Type : Wooden

Packaging Size : APS

Features : Heat Transfer Efficiency:- Good

Colour : METALIC

Usage/Application : Radiant Heating Dies and Manifolds. Immersion Heating. Solar. Textile Industry

Brand : FITZER

Mobile Brand : NA

Type : Low Integral Fin Tube

Country of Origin : India

...more

Waste Heat Recovery System

15,000,000 Per set

1 Piece (MOQ)

WASTE HEAT RECOVERY is a process of recovering ENERGY from waste process outputs. These are custom built equipment or systems designed as per the waste heat available and the process heat load. • These are custom built equipment as per the type waste heat available and the process heat requirements. A detailed study of the client's system is required. • These systems can be designed to recover waste heat from high temperature flue gases of furnaces , DG sets, boilers or any other heat source. • The waste heat recovery can be designed in shell and tube type or water tube type design based on the operating pressure of the system. SMOKE TUBE TYPE WASTE HEAT RECOVERY SYSTEMS : • Package type boilers is an internal furnace Boiler with a three pass, fully wet back & smoke tube type design. The fuel is charged through a charging door to keep the fire going. Package type is designed to provide low cost heating with minimum operational complexity. • Due to proper shell or steam drum diameters, steam volume is more & hence better steam quality. • Steam Quality is better as Properly Designed Drum Internals are Provided. • Provided with accessories like Economiser, Deaerator Tank etc. as per requirement for better performance of the Waste Heat Boiler. • Capacity and Working Pressure of the Waste Heat Recovery is considered as per Customers requirement. • Heat Exchangers and Waste Heat Recovery Boilers are especially made as per codes like IBR 1950 with its Latest Amendments/TEMA etc.

Type : Automatic

Application : Waste Heat Recovery

Weight : As Per Designed

Voltage : 380V

Power : 5-7kw

Driven Type : Electric

Warrenty : 1 Year

...more

HIGH PRECISED CUSTOMIZED ALUMINUM FABRICATION

30,000 - 1,000,000 Per SET

1 Unit (MOQ)

3mm Aluminium Fabrication is a non-ferrous metal as it didn't consist of iron and due to non-ferrous metal which is more difficult to do fabrication as well as TIG welding on it compare to ferrous metal. Aluminum needs three times more heating power than ferrous metal like stainless steel. Grinding and buffing on Aluminium is quite difficult as it becomes soft and sticky during the Fabrication process. We are offering Aluminum Sheet Metal Fabrication Service to our client. Our name is reckoned amongst leading and reputed industry for providing Aluminum Panel Fabrication. This Aluminum Panel Work service is provided by us as per the client’s needs. The Aluminum Panel Work is done by our experts from best quality material and in various specifications. Owing to the rich industrial experience and expertise in this business, we are involved in providing Stainless Steel Fabrication Service.

Material : Aluminum

Finishing : As Per Drawing/Specification

Shape : As Per Drawing/Specification

Color : Silver, Grey,Shiny Silver

Feature : Accuracy Durable,Corrosion Resistance,Dimensional,High Quality,High Tensile,Non Breakable

Technics : As Per Drawing/Specification

Packaging Type : Wooden

Type : Aluminum Fabrication Equipment

Size : As per Drawing/Specification

...moreOpening Hours

Established in the year 2019, we at Fitzer Incorporation are one of the most renowned and reputed manufacturers, suppliers, and exporters of industrial equipment. We proficiently deal in Heat Exchangers, Heating Process Equipment, Cooling Process Equipment, Desiccant Dehumidifier, IQF Tunnel Freezer, Cold Storage Room, Convection Recuperator, Pressure Vessels, Storage Tanks, and Thermal Energy Storage systems. All of our products are manufactured and designed as per the global standard such as API, ASME, IBR, TEMA, and ASHRAE.

We have established world-class transportation equipped with advanced and newest technology machines that assists us in organizing the products with dimensionally accurate, extremely efficient, highly durable, corrosion-resistant, and strong construction. Moreover, with the highly demanded items, we give properly planned fabrication-erection services for industrial plants by offering system designs, fixing, and after-sales services.

We have appointed a team of professionals and well-trained experts who are aimed to create machines to manufacture products from the best quality raw materials following the best industry terms and norms.

Our team of quality controllers performs a series of tests to inspect the overall quality and operations of the products.

Fitzer Incorporation is working under the able motivation and guidance of Mr. Siddhi Chavan. Since our beginning, we have followed the policy of blending price and quality for offering the best possible items to valuable customers. We aim to increase our business shortly while keeping up our striking track record.