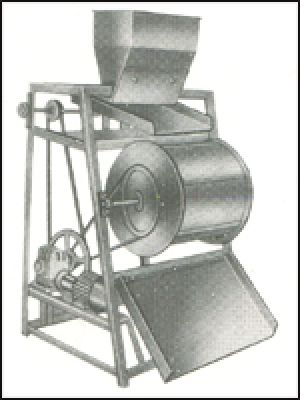

Triple Drum Type Permanent Magnet Separator

Specification With reduction gear, 1 HP 3 Phase Electric Motor to drive the drum at a speed of 15 RPM, Vibrating Tray fixed in between Hoopper and Drum,extrahigh power permanant magnetic plate at bottom side & Machine complete with close body.Salient FeaturesDrum consists of high coercivity modern anisotropic Permanant Magnets.Strong & rugged construction.Automatic separation of iron impurities.Completely closed design to avoid dusting and air pollution.

...more

Suspension Magnet

Suspension type Magnets are useful for products carried by the Conveyor belt.Suspension Type Magnets use is recommended for low contamination products. If the frequency of the impurities is very much, it will make a layer shunting magnetic field. Hence, the equipment required frequent cleaning. Over band type Magnetic Separator is recommended for this type of application.The principal applications are for processing of bulk products such as Culets, Glass, Co fee, Cereals, Minerals, Coal and Sugar etc.InstallationNirmal Magnets can be installed at the end of belt above the head drum (Image-1) or across the Conveyor belt (Image-2).To avoid disturbances to the magnetic field, in both cases, the magnetic parts must be placed below the surface of the magnet.The installation shown in Image-1 is recommended for high speeds. Due to trajectory of the products and the fact that it is then fluidizes, separation is more efficient.

Condition : New

Warranty : 1 Year

After-Sales Service Provided : YES

Size : 145mm

Application : Industrial

...more

Rare Earth Tube Magnet

Composite : Neodymium Magnet

Grade : 33H-42H, 33SH-40SH

Rare Earth Grids

Power Magnet

Application : Power Cord Use

Feature : Hopper Magnet Consists of High Corocivity Modern Anisotropic Permanent Magnet like Ferrite / Rare Earth Magnet.

Diameter : 27mm

...more

Permanent Magnet Drum Separator Without Vibrating

Permanent Magnet Drum Separator With Vibrating

permanent magnetic drum pulley

The permanent Drum Separators are available in standard drum diameters of 300 mm, 400 mm & 450 mm. Drum length range from 300mm to 1200mm. Other sizes can be made as special to your requirement. The larger diameter and length of the drum the greater is the volume of material Which can be handled.nirmalmagnet industriesWorking Principle & Megnetic SystemThe Permanent Magnetic Drum consists of a stationary Permanent Magnetic assembly having uniform and everlasting Magnetic field accross the entire width of drum, which is effective overapproximately half the drum circumference as shown in Fig. Drum Shell made of non Megnetic stainless steel revolves around the magnetic field. As the material fed evenly from the chute falls over the drum, powerful magnetic field attracts and holds ferrous particles to the revolving shell as the revolving shell carries the Iron particlesthrough the stationary magnetic field the non-magnetic meterials falls frelly from the shell while ferrous particles are firmly held until carried beyond devider and out of magnetic field. The strength of the permanent magnetic drum is guaranteed to be greater than corresponding electromagnetic drum, The Permanent magnets used are everlasting magnets and its strength does not diminish during normal use and can be used through out the life of the installation.

Material : Metal

Application : Stone Crusher

...more

Permanent Magnetic Pulley

Features 304 stainless steel faces. Removable mild steel shaft. Four hub styles. Flat face. Keyway and set screws. Options Taper locks Crowned face Fixed shaft Lagging Stainless steel shaft

Material : Stainless Steel, MS

Usage : Industrial

...more

Overband Magnet Separator

ApplicationsSeveral types of separators are developed to operate at pre determined working space over the conveyor i.e. 100,150,200,250 and 300 mm. while choosing the over band, the speed of the belt, the nature of the product,its density, its granulometry and size of the particles, which have to be extracted are the main parameters to be taken into consideration.Construction2 “U” Section pieces are fitted on the magnet by fastening ears and are supporting bearings of drums and the drum are equipped with shafts mounted on removable hubs. All the bearings are equipped with stakes for tightening the belt. Reduction gear coupled Electric Motor/Geared Motors by vee belts drives the belt.Magnet UnitThis Magnet is developed from high Intensity Strontium Ferrite Rare Earth Magnets and guaranteed to give full magnetic power in the entire life span of installation. One Non Magnetic Stainless Steel Plate is supplied to cover the poles of the magnet. No need for electrical supply or maintenance.InstallationThese Magnetic separator can be installed either inline over the terminal head pulley (Image-1) or traversal to the Conveyor (Image-2). For both cases, it is required to foresee Non-magnetic products under the magnetic filed. Most suitable position is inline (photo-1) over the head pulley. The material being conveyed is in virtual suspension and tramp iron is therefore more readily extracted. Good results are obtained by combining a permanent Magnetic over and with permanent Magnetic pulley at discharge end.

Weight : 450kg

Warranty : 1 year

Material : Metal

Usage : Industrial

...more

Magnetic Plates

Thickness : 2-5 mm

Condition : New

Application : Industrial

...more

Magnetic Floor Sweeper

Application : Cleaning the floor

After-Sales Service Provided : Engineers available to service machinery overseas

Cleaning Process : Cold Water Cleaning

Color : White or as requested

Feature : Critical Cleaning / Residue Free

...more

Liquid Trap Magnet

Cartridge-Style Liquid TrapsFor non fibrous fluids cartridge-style liquid traps are ideal. These types of separators are utilized where the size of the contaminants is few diameters and pose no risk of clogging. When the liquid is forced towards the tightly spaced grid, the contaminants come in the effect of magnetic field, which is extracted from the liquid flow by powerful Rare Earth Magnets The contaminants are held on the cartridge surfaces, which is later removed.Magnetic Liquid Traps- Single PlateSingle plate magnet style liquid traps are effective and efficient in removing ferrous particles from viscous and fibrous liquids and liquids containing large suspended solids. The contaminants are thrusted to the magnetic plates where they are held. The magnetic field is strong enough to trap and protect the tramp materials from the wiping action of the liquid flow. The cleaning is done by removing the plate magnets from the housing and wiping the ferrous tramp to the edge of the plate, where it can easily be brushed away.Magnetic Liquid Traps- Dual PlateDual plate magnet has diverter that creates a smooth flow pattern that protects fragile products from damage. The diverter also divides the product flow over two plate magnets. Thus even the flow rate is higher the dual plate traps can effectively handle it easily. The flow rate can be slowed thereby giving more magnetic protection. Also more contaminants are exposed to the magnetic field in the dual plate magnetic liquid traps.Specifications The liquid trap magnets are equipped with powerful Rare Earth Magnets of high-intensity there by capturing even the minutest ferrous fines. The trap magnets come in different forms like single plate, dual plate cartridge’s type etc. They are easy to mount and operate. The liquid trap magnets are housed in stainless steel structure. The entire flow of the liquid is covered by the cartridge in cartridge liquid magnets which creates strong magnetic force and capture the tramp iron and ferrous particles. Applications Food industries Pharmaceutical Chemical product flows Rubber industries Plastic industries

...more

hump magnet separator

In the line of manufacturing different products, we have our products as Magnetic Equipment Vibrating Equipment Conveyor System More concerned about customer satisfaction we adopt different policies for customer care. Each of our products is subject to strict quality control measures to ensure that only the best in terms of quality and design reaches the market. We believe that our clients know us for the quality that we provide and are fully aware of our responsibility of catering to their needs and requirements in this regard. Half Hump Magnets:Our Half-Hump Magnets can be applied where Hump Magnets will not fit due to height restrictions. Like its full version, the Half-Hump housing directs the material flow over the single high-strength permanent magnet and breaks up aggregated material to Dis-lodge and capture the embedded metal contaminants.

...more

Hopper Magnets

Grade : N38, N52, N35

Diameter : 2 X 40mm

High Intensity Roller Type Magnet Separator

Operating MethodA Short conveyor belt envelopes the Magnetic Roll and tensioning the Ideal Roll. An efficient Feeder discharges material on the Belt. The Ferro Magnetic and Para-magnetic particles adhere to the Belt while the nonmagnetic particles flow freely off the end of the Conveyor.FeaturesMagnetic Rolls are available in 65, 75 & 100 mm dia and widths upto1200mm . There are three different Magnetic Strengths i. e. 8000 Gauss, 20,000 Gauss and 22,000 Gauss. The Roll is driven by a 0.5 HP, variable speed DC/AC geared Motor drive adjustable from 0 to 100 RPM. For the purpose of Feeding, Vibratory Feeder with Control is provided. The Machine is provided with Abrasion resistant endless conveyor Belts of 0.8mm thickness.ApplicationsNirmal Machines are most suitable for various types of Industrial Minerals applications i. e. Abrasive, Refractory and Ceramic Raw Material beatification, Alumina, Silica, Carbide, Magnetic, Quartzite, etc. Glass Raw Materials, Clean Silica Sand, quartz, Feldspar, Dolomite etc., Ultra High Purity Quartz Cleaning, Graphite Upgrading, Manganese Orebenification, Bauxite Upgrading, Diamond ore benification, Selective Separation of Garnet / Ilmenite/Rutile, Zircon, Benification of Iron ore, Recovery of Metals from Slag, Removal of Ferro Silicate from Limestone, Megnesite etc.

Application : Power Cord Use

Feature : Hopper Magnet Consists of High Corocivity Modern Anisotropic Permanent Magnet like Ferrite / Rare Earth Magnet.

Diameter : 27mm

...more

grill Magnets

Material : Steel

Shape : Round / Square / Rectangular

Application : Pharma / Food / Dyes & Imtermediate Ind

Structure : SS 304 / 316

Diameter : 16 inch

...more

Funnel Magnet

Size : 140mm (W) X 170 Mm (L) X 25 Mm

Diameter : 55 Mm.

Length : 150 Mm.

...more

Ferrite Magnets

Rings, Rectangulars, Square, Segments, Discs, Cylindricals, Plasto-ferrite / Rubber Sheet / Strips, etc.Any other shapes and sizes, not available in the country at present, could be supplied in accordance with the client’s requirement.Our factory is well equipped with latest sophisticated machinery catering to the need for Magnetic Chuck, Separators, Grills, Holding Systems, etc. Magnetos, DC Motors, Stepper Motors, Generators, etc. Moving coil Instruments, Magnetic Door Catches, Magneto Theropy. Loud Speakers, Horns Public Address System etc. Fabricators, Automobiles, Auto Switches, Coupling Oil Filters etc. Magnetic / Strikers/Boards, Laboratories & Schools Conveyors, Trollies, Gifts & Novelty Items, Televisions Computers, Refrigerators & Relays. Our Products were lunched in the market only 4 year back and have earned a high reputation in terms of quality and timely supply. Our magnets are fully guaranteed for its best performance. However, minor defects like hair line cracks, chipped edge or corner which are unavoidable due to nature of material. These defects are acceptable only, if they do not change the magnetic performance of the piece. Kumar magnets has carved out an unique place for itself at the forefront of magnet technology – with a reputation for the highest quality standards reliability and dependability of timely supplies-and the creditability that goes with it. the confidence that has been generated, thus, will be our springboard into the future – into more challenging vistas calling for the highest technical ingenuity and the most prudent resource management. Partners in each others growth through a commonality of interests. DISC MAGNETS are also available in isotropic material which do not have any specific directions, they can be magnetized by any one of the 3 axes. Isotropic Disc Magnets are available from 4.00 mm to 50.00 mm diameter and their varying heights.

Composite : Neodymium Magnet

Grade : 33SH-40SH, 33H-42H

...more

Drawer Magnet

Heavy DutyHeavy duty drawer are useful for optimum magnetic separation in tough processing conditions like ambient temperature and humidity, bridging, abrasion, corrosion or galling. There are special coating on the drawer’s tubes that prevents sticking problems associated with certain products and processing conditions. Due to this the cleaning operations becomes even easier. The cleaning can be accomplished both manually and automatically.Large TubeIn larger drawer magnets Rare Earth Magnetic tubes are incorporated for optimum ferrous metal separation on difficult flowing products such as flour, powdered sugar and other products with a tendency to bridge. The placement of larger tubes below steep angled diverters that prevent product from bridging or building up on the tubes. Since the spacing between the tubes are larger it allows the product to flow freely through the housing.Manual CleanFor low levels of tramp metal contamination, manual clean drawer magnets are ideal. The Magnetic tubes are located on the alternating centers of the tubes. The trapped materials can be removed with the help of shop rag or gloved hand.Self-CleaningIn difficult locations Self-cleaning Magnetic Drawer is considered as suitable. Through the toggle switch the operator can easily clean the assembly from a remote location.Features The drawer magnets can be fitted simply in existing pipe line or outlet of various equipments like pulverizers, blenders etc. Generally each unit comprises of permanent magnetic grids mounted one above the other. For special applications there are systems with multiple grids. The grids are easily removable for cleaning. Normally the ferrite or rare earth and NdFeB magnets are used in the drawer magnets. Certain types of drawer magnets handle a wide range of separation tasks in gravity conveying systems ApplicationsThe drawer magnets can be applied in following areas: Mining industries Pharmaceuticals industries Food processing industries Industries dealing with powdery substance Cement, gypsum and other types of small scale industries.

Material : Metal

Grade : N52, N35

Type : Based On the Sizes

Application : Industrial

...more

Double Drum Type Permanent Magnetic Separator

SpecificationWith reduction gear, l HP 3 Phase Electric Motor to drive the drum at a speed of 15 RPM, Vibrating Tray fixed in between Hopper and Drum extra high power permanent magnetic plate at bottom side & Machine complete with close body.

...moreBe first to Rate

Rate This