Vessels & Stirrers

SIGMA Glass vessels & glass stirrers provide the best solution for all requirements encountered in production processes because of the wide range of glass vessels available. Borosilicate Glass Vessels in either unjacketed or jacketed form are essential components of many units & plants. The Glass Reaction Vessels can be combined with various components as stirrer drive, vessel covers & heat exchangers to construct the wide variety of stirred units & reaction systems. These glass vessels find universal application as reactors, receivers, reboilers, separators, measuring, feed vessels & glass storage vessels in the chemical industry. The complete range of standard glass vessels is available up to 300-liter capacity.

...more

Valves & Filters

SIGMA valves & filters can be relied upon to require minimum maintenance & to provide maximum reliability. These valves & filters provide the relatively easy on-off function to control flow & pressure relief. All wetted parts of valves & filters are made of borosilicate glass 3.3 & PTFE, which ensures maximum resistance to corrosion. The complete valve consists of Glass Valve Body, PTFE Bellow with nut, Bakelite Valve Bonnet with MS Spindle etc. Different types of valves like Line valve, Drain valve, Bottom outlet valve, Vent valve, Adjustable overflow valve, Non-return valve (flap type), Non-return valve (ball type), Pressure relief valve, Sampling valves are available. Pipeline filters are recommended to remove impurities from gas & liquid streams in glass pipelines. The assembly is designed such that the filter can be easily removed for cleaning or replacement.

...more

Tubular Supporting Structure

SIGMA structure is designed to support plant and other equipment in borosilicate glass 3.3 These structures are available in the form of modular system that not only meets standard requirement but also facilitates solutions for problems of unique nature. These structures consist of steel tubings, which are connected using the appropriate fittings. As a result, these structure can be assembled, dismantled, expanded or modified very easily & quickly. Standard support is made of G.I. tubes with C.I. fittings. For GMP application SS pipes with SS fittings are used.

...more

TRIPLE WALL GLASS REACTOR DESIGN

Sigma started manufacturing SIGFOLDI – TRIPLE JACKETED® reactor up to 50Ltr. Cap. from an entirely new design with design Registered No. 1681023. Vacuum Jacket Eliminates heat losses to the atmosphere and allows the process to be monitored with no frost formation on the jacket for operations below freezing point. The vacuum is extended over the service nozzles to facilities a clear view. PTFE spiral Baffle can be fitted between Reaction Vessel and the service side of the jacket for maximum efficient heat transfer area utilisation. All reactors are designed with little dead spaces to keep L/D Ratio within 1.0 to 1.5 for the safety of the equipment, smooth performance and easy scale up. Operation Temperature Range : -80°C to +200°C

...more

Thin-film Evaporator Design

Thin – film Evaporators are vertical, Mechanically Operated Continuous Film Evaporator designed for difficult concentration, extremely heat sensitive materials wherein the unit operations like Distillation, Evaporation and Stripping can be conducted. This technology gives the ability to remove volatile components from less volatile materials that are heat – sensitive, viscous, foaming, or contain solids. It offers short residence time, thin film formation by the centrifugal force of the rotating wiper system, the speed of which, can be adjusted to the viscosity of the product to be evaporated, which increase the evaporation efficiency. This is possible by the creation of the uniform film on the smooth heated surface of the glass body. Of late, the demand for test and pilot plants for gentle distillation has considerably increased in Fine Chemicals, Pharmaceuticals, Foods & Beverages industry. The Constantly rising number of new products and rising world market price of raw materials are responsible for this demand. Salient Features: Maximum Evaporation in Single Pass The Roller – wiper system (fully corrosion resistant construction) makes possible to attain a homogenous mass of liquid mixture and high wiping speed maximise evaporation efficiency. Minimal to no degradation of thermally unstable materials. The Capability of Handling High Viscosities. High surface to volume ratio Higher Heat Flux due to uniform film formation No dry spots and no fouling. Easy to clean, install and maintain Thin- Film – Evaporators are available in DN-80 X 0.15m² to DN-150 X 0.5m² Evaporation surface Area. Thin – Film – Evaporators can be run up to 200°C Product side and 230°C Jacket Side. Thin – Film- Evaporators can be run under Jacket Pressure of 2.0 bar (g) and evaporator can be operated at the vacuum of 5mm Hg to 0.005mm Hg. All wetted – parts that make contact with liquids or gases are made from high precision Borosilicate Glass Tube and PTFE

...more

Simple Distillation Unit

It consists of a vessel mounted in a heating bath and fitted with a condenser for condensing the fumes. Receiver with drain valve can be added for receiving the condensate. The unit is available in vessel sizes of 20, 50, 100, 200, & 300 Ltr.and is suitable for operation under atmospheric pressure and full vacuum. Optional items Heating mantle instead of jacketed heating/cooling bath. Flush bottom valve instead of the simple drain valve. Cylindrical vessel instead of the spherical vessel. SIGFOLDI-JACKET ™ vessel instead of the spherical vessel without heating bath and heating mantle.

...more

SIGMA CLASS GLASS JACKETED REACTOR DESIGN

SIGFOLDI – JACKATED® ( First time in world’s glass ind.) is manufactured with 100% folding design up to a nominal capacity of 200 Ltr. Which is registered under Patents Registration No.: 207576. It is a system of two concentric vessels held together by flange and seal arrangement. The end flexible seals absorb the different expansion levels and prevent high stresses of the inner component and the jacket by allowing the movement flexibility between two due to thermal expansion. Fused Jacketed Glass Reactors are at a huge disadvantage in case of damage to the system due to mechanical impact are not repairable and have to be discarded. While in our system, if per chance the inner vessel or outer vessel get damaged either is replaceable adding to the longevity of the equipment. All our reactor systems are designed to keep L/D ratio within standard limits. Because of being a two component i.e. Vessel and Top cover agitators can be designed for the maximum sweep for better mixing & turbulence with no vortex formation by very effective second stage pitched blade agitator.

...more

Sight Glass

The sight glass is a device used between any kind of non-transparent pipeline to observe the flow of liquid. This can be used both in horizontal as well as a vertical pipeline. The sight glass is constructed in such a way that it gives a complete view from every angle.

...more

Sigfoldi-triple Jacketed Reactor And Glass Reactor With S.S. Jacket

Operating Parameters Pressure Range : Full Vaccum up to 0.5 bar (g) Temperature Range : -80°C to +200°C Capacities : 5 L up to 500 L Installation Sites : R & D Lab, Pilot Plant, Kilo Lab, Production. Salient Features : GMP design Skid Mounted / Lab – Hood Adaptability Documentation Instrumentation Safety Control Pure and corrosive Media Handling Safe operation Customized Reactor System-for up scaling Excellent thermal Process Control Reactor Bottom Pan Single wall Round bottom Reactor up to 300L Single wall Cylindrical Reactor up to 500L Double wall Cylindrical Jacketed up to 200L Triple wall Reactor up to 50L Glass Lined Reactor (20L,50L,100L,250L), pre-insulated (with SS cladding) Glass Reactor with SS Jacket ( Pre insulated with SS cladding ). Reactor Top Cover Glass Top Cover Glass Lined Top Cover PTFE lined / Coating Top Cover Bottom Outlet Valve Flush bottom outlet valve – Glass / PTFE Glass lined with Temperature Sensor ( Optional ) Flush bottom outlet valve with Temperature Sensor Stirrer System Easy interchangeable stirrers made of PTFE lined Glass lined, anchor, turbine agitators PTFE coating/ lined Anchor, Pitch blade turbine, interchangeable impellers also. Glass stirrers with PTFE Blade, Vortex Stirrer, Propeller Stirrer Motor : Flame Proof, Speed control by VFD or mechanical variator with suitable gear box. Seal : Sic, Single dry running Complete SS construction ( option ), SS hood for motor, gear box, housing Safety Devices Rupture Disc Vent nozzle in Jacket ( For Glass Jacketed Reactor only) Glass / PTFE Pressure Relief Valve Coating of Glass components to avoid static discharge PTFE thermometer pocket with Tantalum Tip

...more

SIGFOLDI-JACKET

SIGFOLDI – JACKET™ is manufactured using borosilicate glass with 3.3 coefficient of expansion. They have proved their worth to Excellent effect through out the chemical and pharmaceutical industries as well as many related areas such as food and drink production. For special applications, cylindrical vessels can be supplied with a jacket for heating or cooling. Up to a nominal capacity of 200L (First time in world) SIGFODI-JACKET™ with full bore diameter, top branch can also supplied with a borosolicate glass 3.3 jacket In the SIGFOLDIJACKET™ flexible seal is used on the upper end and bottom outlet branch with special designed CI/M.S./S.S Flanges. Which design is Registered.

...more

Rotary Film Evaporator

A rotary evaporator is a device used in Chemical Laboratories for efficient and gentle removal of solvents from samples by evaporation. The main components of a rotary evaporator are: The motor unit which rotates the evaporation flask containing sample material. A vapour duct which acts as an axis for sample rotation, and a vacuum tight conduit for the vapour being drawn off of the sample. A vacuum system (not integral part of the equipment) to substantially reduce the pressure within the evaporator system. A heated fluid (water thermic fluid) bath to heat the sample being evaporated. A condenser with double coil through which the coolant passes. A condensate collecting flask at the bottom of the condenser, to collect the distilling solvent after it recondenses. A mechanical or motorized mechanism to quickly lift the evaporation flask from the heating bath or lower the heating bath so that the evaporation flask does not remain in contact with bath.

...more

Rotary Evaporators Design

A rotary evaporator is a device used in Chemical Laboratories for efficient and gentle removal of solvents from samples by evaporation. The main components of a rotary evaporators are: The motor unit which rotates the evaporation flask containing sample material. A vapour duct which acts as an axis for sample rotation, and a vacuum tight conduit for the vapour being drawn off of the sample. A vacuum system (not integral part of the equipment) to substantially reduce the pressure within the evaporator system. A heated fluid (water / thermic fluid) bath to heat the sample being evaporated. A condenser with double coil through which the coolant passes. A condensate collecting flask at the bottom of the condenser, to collect the distilling solvent after it recondenses. A mechanical or motorized mechanism to quickly lift the evaporation flask from the heating bath or lower the heating bath so that the evaporation flask does not remain in contact with bath. The vacuum evaporators as a class function because lowering the pressure lowers the Boiling Points of component liquids in it. Generally, the component liquids of interest in applications of rotary evaporation are solvents that one desires to remove from a sample after an extraction, for instance, following a natural product isolation or a step in an organic synthesis. Use of a Rotary Evaporator, therefore allows liquid solvents to be removed without excessive heating of what are often complex and sensitive solvent – solute combinations. Advantages of Rotary Evaporators The centrifugal force and the frictional force between the wall of the rotating flask and the liquid sample result in the formation of a thin of warm solvent being spread over a large surface. The forces created by the rotation suppress violently, un – predicted boiling/bumping. Allows quick and gentle evaporation of solvents from most samples. Low temperature and vacuum control also help in kerbing bumping/foaming during evaporation process.

...more

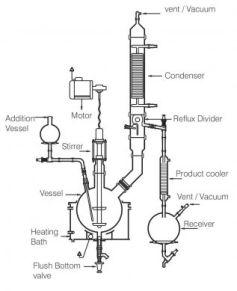

reaction unit

This unit is used for carrying out reactions under stirred condition and with provision for simple reflux distillation. The reaction vessel is mounted in a heating bath and fitted with addition vessel, motor-driven stirrer and provision for condensation with refluxing. The product is sub-cooled and collected in a receiver. The units are available in vessel sizes of 20, 50, 100, 200 & 300Ltr is suitable for operation under atmospheric pressure and full Optional items Heating mantle instead of jacketed heating / cooling bath. Simple drain valve instead of the flush bottom valve. MS PTFE lined stirrer instead of glass stirrer. Variable frequency drives for variable speed. Cylindrical vessel instead of the spherical vessel. SIGFOLDI-JACKET ® vessel instead of a spherical vessel without heating bath and heating mantle.

...more

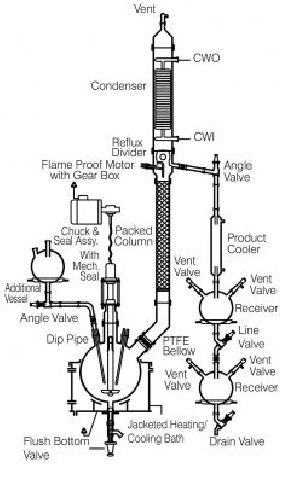

Reaction Distillation Unit

The unit has been designed to suit the customer’s requirement of a combination of versatile reaction/distillation or combination for pilot plant work. This has a flexibility of working at atmospheric pressure as well as under vacuum. The typical unit has a reaction vessel fitted with a metal heating/cooling bath having a facility for heating and cooling bath by means of heating/cooling Fluids as a media. The Standard system is equipped with stirrer heaving mechanical seal, a packed column on the side neck of the vessel, reflux divider, coil type condenser and or receiver system having a product, cooler, vent, drain and vacuum valves, Option of speed variation by mechanical variator or electronic variator can be provided. The receiver system is equipped with product cooler. Vent/vacuum valve and drain valve. The above unit are available in 10 Ltr., 20 Ltr., 50Ltr.,100 Ltr., 200 Ltr. & 300Ltr capacity with a spherical reactor. Optional Items Heating mantle instead of jacketed heating / cooling bath. Simple drain Valve instead of the flush bottom valve. MS PTFE lined stirrer instead of glass stirrer. Variable frequency drives for variable speed. Cylindrical vessel instead of the spherical vessel. TM SIGFOLDI-JACKET vessel instead of a spherical vessel without heating bath and heating mantle.

...more

Pipeline Components

Sigma Borosil glass 3.3 pipeline components are widely used in chemical, pharmaceutical, dyes & allied industries and food & drink production where the advantages of using glass as a basis for the construction of complete process systems have long been recognized. The main reasons for wide acceptance of Sigma borosilicate glass 3.3 are because of (a) Universal resistance to almost all chemicals resulting in reduced contamination risk, (b) Transparency for ease of visual monitoring of the process (c) Smooth surface allows easy cleaning & sterilization of systems. This guarantees long service life & minimum maintenance requirements.

...more

Mobile Gas Scrubber

Simple in design Ideal for scrubbing exhaust from small scale chemical plants Suitable for air and exhaust clean up tasks. Ideal for studies and Scale – up of gas scrubber systems. Sigma offers Mobile Scrubber in all glass and PTFE Construction for use in laboratories. The system is Mounted on stainless steel skid structure for maneuverability.

...more

mixer settlers

These are a Class of mineral process equipment used in Extraction Processes. Industrial Mixer- Settlers are commonly used in the Copper, Nickel, Uranium, and cobalt Hydro – Metallurgy Industries where Solvent Extraction Processes or Liquid – Liquid Extraction Processes are applied. Mixer-Settler consists of a first stage that mixes the phases together followed by a non-active settling stage that allows the phases to separate and a gravity separator where the liquids are separately removed as Heavy Phase and Light Phase. For continuous operation, mixing and settling zones are spatially separated from each other. This can be achieved by connecting a series of several such mixing & settling chambers through which the phases are fed in counter – current flow, the system can be designed as per the requirements of a particular problem. The Critical factor in the design of the horizontal mixer- settler is the coalescence ( to come together to form a mass or whole) rate of the dispersed phases. Mixer – Settler Uses: Extraction Process Washing Process Stripping Process Salient Features Uses: Separation of components in solution Chemical Dispersion or Dissolution Cooling or Heating of liquid by direct contact with another Creating Permanent Emulsions

...more

Mixer Settler

These are a Class of mineral process equipment used in Extraction Processes. Industrial Mixer- Settlers are commonly used in the Copper, Nickel, Uranium, and cobalt Hydro – Metallurgy Industries where Solvent Extraction Processes or Liquid – Liquid Extraction Processes are applied. Mixer-Settler consists of a first stage that mixes the phases together followed by a non-active settling stage that allows the phases to separate and a gravity separator where the liquids are separately removed as Heavy Phase and Light Phase. For continuous operation, mixing and settling zones are spatially separated from each other. This can be achieved by connecting a series of several such mixing & settling chambers through which the phases are fed in counter – current flow, the system can be designed as per the requirements of a particular problem. The Critical factor in the design of the horizontal mixer- settler is the coalescence ( to come together to form a mass or whole) rate of the dispersed phases.

...more

SIGMA measurement and control equipment

SIGMAmeasurement and control equipment complement the component range and helps to ensure that borosilicate glass 3.3 plant and apparatus operates correctly & safely. The full range of standard components is described on the following pages, Non-standard components can also be supplied as per your order

...more

KILO LAB (REACTION / DISTILLATION UNIT) DESIGN

Reaction systems are developed to fulfil the actual needs of chemical and pharma industry. Sigma Reactors are built for batch and semi – batch operation mode, with perfectly matched components and quality materials. Conforming to GMP / FDA Guidelines and Explosion proof installations. Applications Glass Single Wall, Glass Double Wall, Glass Triple Wall Reactor, Glass Reactor with SS Jacket, Glass Lined Reactor with Glass top and Glass Lined Reactor

...more

Hcl Gas Adiabatic Absorbers

Hydrogen Chloride gas produced as a by product can be economically processed into Hydro – Chloric Acid by simple Absorption Adiabatic Absorption is the most effective means of production of Hydro – Chloric Acid solution. Under normal operating conditions Hydro Chloric Acid Solution of 30% – 31% strength can be obtained. These absorbers operate, as the name implies, without any heat input into the reaction zone. The gas loading should in no case fall below 50% of the design maximum for adiabatic absorption column to be most effective means of absorption. In this process HCL – Gas is absorbed by fresh water flowing down the column . The heat generated by this reaction vapourises approximately 30% of the water that rises to the head of the column with non – soluble components of the gas stream. Hydrogen Chloride streams containing air, water vapour & non – condensable are condensed / absorbed within the column and are returned together with the make up water to the bottom of the column through several packed sections and are passed through heat exchangers for dissicipatcing the heat of absorption before storage. The acid out let temperature is 45° C to 50°.

...more

HCl Absorber

Glass Venturi Scrubber

Venturi Scrubber is a device which helps in the mixing of Liquid and gas to achieve the purpose of scrubbing and Absorption. Advantages / Salient Features: No moving parts No Maintenance Ease of Operation Can handle Large Gas Flow Rates Intimate Mixing No space requirement, it can be installed on a tank Can be used as Vacuuming / Dust collection Device. Venturi scrubbers can be used as single or as Multi-stage equipment for higher efficiencies of absorption. Can be used as tail – gas absorber Applications : Gas Absorption Vacuum Generation Fume Scrubbing Dust Collection / Air Pollution Gas Liquid Reaction Feeding of solids to reactors is made easy by negative draft developed by Venturi on the system

...more

Glass Shell and Tube Heat Exchangers

Shell and tube Heat Exchanger are for large heat transfer area, the efficiency of heat transfer and compactness. Shell and Tube Heat Exchanger are widely used as coolers, Condensers, Heaters and Evaporators. Glass Shell and Tube Heat Exchangers are reliable only when leak-free sealing is available between shell & Tube sides. There are two types of Ferrule Sealing in Sigma shell and tube Heat exchangers. Such as: PTFE Ferrule with Gland Packing. PTFE Ferrule without Gland packing. In the case of Ferrule seal with gland packing PTFE ‘O’ Ring & PTFE Rope is used to fill the space between tube and tube sheet and PTFE Ferrule acts as a Gland Follower to make sealing perfect and leak free. And Ferrule without gland packing is a sealing system where the design of ferrule is such that while tightening. The ferrule gets folded at the seal point of Tube – Sheet in such a way that it does not require ‘O’ Ring or the gland rope and gives as good leak free sealing as in the first case. This unique ferrule type sealing arrangement permits easy replacement and cleaning of tubes. Sigma has further improvised on the shell and Tube Evaporators and Re-Boilers with the replacement of Glass Tube by Graphite Tubes and GFT Tube – Sheets. These types are good for high temperature and high-pressure application.

...moreBe first to Rate

Rate ThisOpening Hours