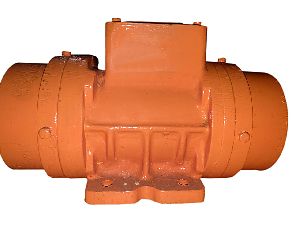

Vibratory Motor

6,000 - 20,000 Per Nos

1 Piece (MOQ)

Vibratory Motor

Get Price Quote

1 Piece (MOQ)

Best Deals from Vibration Motor

Vibrating Motor

Get Price Quote

1 Piece (MOQ)

Vibrator Motor

Get Price Quote

We are offering Vibrator Motor. Excel Magnetic's Vibrator Motor are well equipped with special profile bearings with high carrying load and increased bearing work. It results into long bearing life. Excel Magnetics are manufacturer and exporter of Vibrator motor, vibro motor, motorised vibrating feeder, Vibrating screen, gyro screen, vibro shifter, gyratory shifter, vibro feeder, Ahmedabad, Gujarat, India. Vibrator motor Features :: • Durable • Reliable • High Performance • Value for money.

Vibro Motor

Get Price Quote

Mild Steel Vibration Motor

10,000 Per Piece

1 Piece (MOQ)

Owing to the affluent knowledge, we are capable to provide Vibration Motor. Moreover, the presented series of products is properly checked on varied industry standards to make sure the longer life.

Vibrator Motor

Get Price Quote

CE Vibrator Motor for vibrating equipmentApplications:used in vibrating equipments.Model : : 1 4 hp to 10 hp foot mounted and flange mounted.

Vibratory Motor

Get Price Quote

1 set (MOQ)

MAGWELL Vibration motor excitation force is high efficiency, energy consumption is small, low noise and long life. Vibration motor is power and vibration source of combination of excitation source, vibration motor is installed in the rotor shaft at each end of a group of adjustable eccentric block, using axle and eccentric block high-speed rotating produce centrifugal force get excitation force. It can be applied to general vibratory machines, such as: vibration sieve crusher, extension, vibration falling pressure-blasting machine. SPECIFICATIONS FEATURE: The complete stress relieved MS-cast Iron body (Heavy Duty) Winding Class F Insulation type Power Connection: 3 Ph, 415V, 50Hz. A.C. Supply Standard bearing series are over dimensional in relation to the high speed and stain of strong load to offer increased operational reliability Drive shaft is made of EN 8 Material of tested quality in order to with stain high torque depending on centrifugal force is achieved Steel Unbalanced Counter weight fixed at both side of the Motor with the provision for regulation of the oscillation from zero to maximum Vibratory force by easy adjustment Field operation temperature :- Vibratory motor are design to work from -300 to + 500 Temperature continuously at maximum centrifugal force

Vibrator Motor

8,500 - 10,500 Per Number

1 Piece (MOQ)

Needle Vibratory Motor

5,500 Per Unit

1 Unit (MOQ)

Vibrating Motor

4,800 - 115,480 Per Piece

5 Piece (MOQ)

Electric Concrete Vibrator Motor Single Phase, 3 HP, Model Name

7,000 - 20,000 Per Bag

1 Bag (MOQ)

The honeycomb structure caused by air bubbles can be avoided when using a concrete vibrator. A structure with heavy reinforcement can be easily compacted using a concrete vibrator. When a concrete vibrator is used during the construction of a building, it becomes compact and waterproof. When using a concrete vibrator, a lower water-cement ratio can be used in construction. The speed of work increases when a concrete vibrator is used.

Vibrator Motor

Get Price Quote

10 piece (MOQ)

DC Vibration Motor

30 - 600 Per Piece

1000 Piece(s) (MOQ)

Vibrating Motors

Get Price Quote

For the production of our finished products, we source the raw materials only from the certified and trusted vendors after checking against numerous quality parameters. With the advancement of technology, we have also adopted a secure payment procedure that is easy to use and featured with multiple options.

Three Phase Vibration Motor

1 Per Piece

1 Piece (MOQ)

Electric Vibratory Motors

Get Price Quote

"Miracle" make vibro electric motor in single and three phaseavailablein foot - flange -centreflange mounted with "f" class electric motor winding insulation, Backed by rich industry experiences, we are highly engaged in offering a premium quality range of "MMIRACAL" Single Phase Vibro Motor. Owing to its high performance and excellent functionality, the offered motor is highly applauded among our precious clients.

FOOT BASE VIBRATORS MOTORS

Get Price Quote

Foot Base Mounted Motor Sonal has a wide range of FOOT BASE VIBRATORS MOTORS to meet the requirement of various industries where in material handling plays a major role. These vibrators help to empty, dose, convey, loosen, test, clean, screen, compact, distribute, feed etc., & therefore have a very wide application in Mining, Fertilizer, Chemical, Parma & Food Industry etc Sonal-FOOT BASE VIBRATORS MOTOR vibrators Motors are robust, reliable, highly loadable, quite running and require no maintenance are totally enclosed, surface cooled units operating 415 / 440 volts, 3 phases, 50 cycles. A.C. Supply. Generously dimensioned cylindrical roller bearing, self-lubricating maintenance-free, long life expectancy. The vibrating frequency depends on the revolutions of the rotary unit & can be chosen from four ranges available via, frequencies are 3000, 1500, 1000, 750 vibrations per minute. When used as a single unit, they impact circular vibrations. If directional vibrations are needed, two vibrators running in the opposite direction should be use. The Centrifuge force can be adjusted from zero to maximum by manipulating the relative positions of the eccentric weights provided on either side of the shaft. Various models are available giving a wide choice of Centrifugal force, frequency of vibration, mounting position, Insulation etc. The customer is therefore assured of getting the most suitable vibrator to meet these requirements.Salient Features: Sturdy & robust construction. Totally enclosed dirt & dust proof construction. Amplitude of vibration can be controlled. Heavy-duty bearings for long & trouble free operation. Centrifugal force can be adjusted from zero to maximum. Low noise as compared to Electromagnetic Vibrators. Low maintenance due to absence of belts, pulleys, chains sprockets etc. Application in various industries: Construction industry Industry of building materials Mining industry Chemical industry Packaging and food industry Mechanical engineering Application techniques: Compaction Transport Evacuation / emptying Screening / grading Draining Dosing Deaerate Distribution Sizing / sorting Dust collection Loosen up of bulk materials Center Flanged Motor Sonal has a wide range of CENTER FLANGED VIBRATORS MOTORS with flange fixation, covering all the applications needs on vibrating equipments for screening, finishing, drying and other processes that use vibrating motors with this fixing system. SONAL-CENTER FLANGED VIBRATORS MOTORS are robust, reliable, highly loadable, quite running and require no maintenance are totally enclosed, surface cooled units operating 415 / 440 volts, 3 phases, 50 & 60 cycles. A.C. Supply. Generously dimensioned cylindrical roller bearing, self-lubricating maintenance-free, long life expectancy. The vibrating frequency depends on the revolutions of the rotary unit & can be chosen from four ranges available via, frequencies are 3000, 1500, 1000, 750 vibrations per minute. The Centrifuge force can be adjusted from zero to maximum by manipulating the relative positions of the eccentric weights provided on either side of the shaft. Various models are available giving a wide choice of Centrifugal force, frequency of vibration, mounting position, Insulation etc. The customer is therefore assured of getting the most suitable vibrator to meet these requirements. Three Phase Input Voltage: Standard executions 50Hz 220-230/380-400V , 60Hz 220-240/440-480V (for series EVR-EVS 50Hz 380-400V; 60Hz 440-480V). Special input voltages available on request. Speed (vibrations/minute): Standard: 2 poles: 3000 rpm - 50Hz 3600 rpm - 60Hz 4 poles: 1500 rpm - 50Hz 1800 rpm - 60Hz 6 poles: 1000 rpm - 50Hz 1200 rpm - 60Hz On Request: Speeds not listed as standard two speeds motors 3000/1500rpm or 1500/1000rpm Duty Continuous duty at the maximum centrifugal force (S1), with the possibility to adjust the force from 0 to 100% following the specific graded plate on the eccentric weights (for those series/models supplied by OMB complete with weights). Electric Motor Electric motor realized with low loss silicium magnetic lamination core allowing increasing the efficiency while reducing heating up. Insulation Class : F standard, H on request. Tropicalisation: Windings impregnation realized with ASTM system, with polyester resin class H. Ambient Temperature: From -20°C a +40°C (-4°F/104°F). Overheating Protection: Electric motor protected by Thermistor (PTC set at 130°C) as standard for sizes 50 and 70 (available on request on smaller sizes). Motor Shaft: Shafts in NiCrMo steel, heat treated. Main Body: Mechanical structure designed to withstand the high stresses, realized in cast iron high resistance Painting: Electrostatic powder painting, epoxy-polyester, polymerized in oven. Color: Blue RAL 5010. Bearings and Lubrication: High load capacity bearings, in special executions to withstand the stresses of high centrifugal forces and vibrations, over-dimensioned to grant maximum reliability in vertical use. Special “Long Life” grease lubrication. Mechanical seals with low friction to grant excellent protection, without over-heating and without extra power absorption, keeping their efficiency for long time. Some models as a standard, others on request, are provided with bearing housing with double lubrication entry, to grant that lubrication grease inlet is always from upper side of the bearing.

Vibraotor 1Hp Motor

Get Price Quote

Vibratory Motor

Get Price Quote

As a well-known Manufacturer and Supplier of Vibratory Motors in Chennai (India), we offer a dependable product. The Vibratory Motors, offered by the company, are fully enclosed with a 3-phase squirrel cage induction motor that comes with an eccentric weight that is mounted on both the shaft ends and is adjustable as well. By the adjustment of both the eccentric weights of the Vibratory Motor, the rate of vibration can be easily varied. The point of caution is the selection of shaft material and bearing as it has the capability of altering the capacity to withstand heavy radial load. About Vibratory Motor Mainly used in vibratory screen, feeder, silos, bin and other material handling equipments Available in foot mounted and flange-mounted types Can be availed in different capacities Efficient and requires low maintenance