Single Roll Crushers

Being a reliable name in this arena, we make sure that the payment procedures remain secured with us. In addition, we issue invoice to the clients stating all the relevant information of the products. Our complete range of product is wrapped in strong, nontoxic, and superior-grade packs that protect the contents inside from damage, moisture, logistic movement, etc. Furthermore, the packaging has product details printed on it. Function Ajmani manufacturers the single roller crushes separate the field material with high pressure in the wedge-shaped crushing space between the toothed roller and the adjustable crushing balancer The driven toothed roller draws the material into the crushing gap. Due to the high impact rate of the circulating crushing tooth segments the effective crushing action starts already above the toothed roller. Design Welded robust housing Roller core shaped as a polygon with surface –ground supports for the crushing tooth segments. Locking of the segments by means of dovetail guides and fastening by screwed bolts Tooth shape and tooth pitch are adapted to the respective application Crushing tooth segments individually replaceable without lifting the crushing roller out. Crushing roller alternatively available with crushing rings. Crushing roller with dust-tighy encapsulated anti-friction bearing Stepless setting of crushing gap with optional mechanical or hydraulic overload protection Parallel evasion of crushing balancers on the occurrance of uncrushed components of the material Fields of application Cement, gypsum, and limestone Coal and Patash Mining Building, glass and chemical industries Metallugical plants Advantages Compact design Simple Maintenance High throughput Preserving crushing action Low undersize shares Scarcely any dust accurrence To enable our experienced engineering staff to recommend the installation best suited to specific applications,answers to as many of the following questions as possible will result in a prompt and accurate solution to your screening requirements Material to be crushed Maximum feed dimension Approximate feed size analysis Moisture content Stickiness Bulk Density Product sizes required Friability Abrasive Characteristics Do you intend close circuit operation Capacity desired in tons per hour

...more

Reciprocating Feeders

We are functioning from Asansol(India); we are capable of serving the clients in a short time span. Apart from online payment processing methods, we also facilitate payment through offline mediums.

...more

Conveyor Pulley

Our complete range of product is wrapped in strong, nontoxic, and superior-grade packs that protect the contents inside from damage, moisture, logistic movement, etc. Furthermore, the packaging has product details printed on it. We are a reliable name in this arena and thus make sure that the services offered by us for payment are easy to use as well as offer hassle-free and instant transactions.

...more

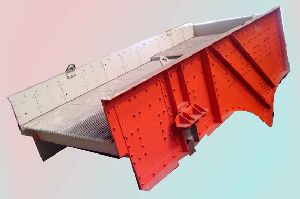

Linear Motion Screen

We promise to make delivery on time, as we have a wide spread network of logistic service providers and dealers. Being a high-flying name in this arena, we promise to deliver the best in line quality products. In addition to this, we make sure that the offered lot is prepared using the finest grade material. Details Linear Motion Screens are operated either by a mechanical exciter or two unbalance motors. In both cases rotation in opposite directions creates linear vibration. Linear motion screens are very high performance machines, in terms of capacity and efficiency. They have a low inclination which varies between 0 degree and 15 degree due to this low inclination required head room height too becomes low. The drive is a combination of high amplitude and low frequency of vibration. The Linear Motion Screens are bolted Single , Double or Triple deck structure with a substantially rigid design. The screen body consists of the two side plates with bolted transverse supports and screen mounts. The screen box is based on an open design. The vibrating screen is supported above the substructure by means of helical coil compression springs. The screen installation angle can be varied to suit the application. The drive is through direct force exciter and Cardon shaft. The angle of throw is determined by the construction and application but usually 35 to 60 degree. The counterweights can be adjusted in stages from 50 to 100%. for variation of amplitude. There are several options for lubrication, oil or grease, which can be used without modification. Selected bearing seals ensure a long service life. Applications:With single or multiple screen decks Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite. Minerals, Ores, Pellets, Sinter Sand and Gravel, building materials Chemical Products, Fertilizers Compost, Refuse, Refuse Slags

...more

Impact Hammer Crushers

Working in assistance with a brilliant inventory management system and capacious storehouse has enabled us to entertain urgent and massive requirements of the customers. Being a prominent name in this area of operations, we, as a Supplier, bring forth qualitative array of Impact Hammer Crusher. Function Ajmani impact hammer crushers crush the material by the reciprocal effect of impact and friction between the hammer heads and dht hammer path Ratio speed and the gap between hammer heads and the hammer path determine the final grain size. Design Welded casing Side parts hydraulically swivellingh Big inspection doors Screwed lining with high-carbon steel plates Hammer path with wear-resistant baffle plates which are mechanically or hydraulically adjustable at all pivot points Dust-proof bearing of self-aligning rollers on the rotor shaft Rotor in disk-type design Resersible or single-direction design Hammer heads made of chrome alloy cast steel or composite casting Direct or V-belt drive Advantage Coal and Potash industries Steel works Gypsum and limestone plants To enable our experienced engineering staff to recommend the installation best suited to specific applications, answers to as many of the following questions as possible will result ina prompt and accurate solution to your screening requirements. Material to be screened Maximum feed dimension Approximate feed size analysis Moisture content Stickiness Bulk Density Separation sizes required Friability Abrasive Characteristics Do you intend close circuit operation Capacity desired in tons per hour

...more

Impact Crusher

We have parted our infrastructure into several units and one of them is storehouse. We update it on regular basis so as to meet stated industry standards. The assistance of our quality auditors helps us in acquiring quality-approved raw materials from the certified vendors. Thus, we ensure that our products are of unmatched quality. Function Ajmani the manufactures impact crushers crush the feed by the reciprocal effect of shock and impact. Rotating baffle plates pick up the material and fling it against the armoured impact vibrators. During the impact the material is split at the natural cleavage faces to become cubical final products Without cracks. Design Welded ,rugged casing Screwed lining with high-carbon steel plates Hydraulically swiveling upper part Detachable connection of disk-type rotor and shaft Replaceable baffle plates,quadruple exploitation Dust proof self-aligning roller bearings of the rotor shaft Pendulum suspension of the impact vibrators Infinitely variable mechanical or hydraulic crushing edge adjustment Pros Rugged structural shape Easy maintenance High degree of crushing Insensitive to foreign substance Application Cement and limestone plants Coal, ore and potash mining Building, glass and chemical industries Steel works To enable our experienced engineering staff to recommend the installation best suited to specific applications,answers to as many of the following questions as possible will result in a prompt and accurate solution to your screening requirements Material to be crushed Maximum feed dimension Approximate feed size analysis Moisture content Stickiness Bulk Density Product sizes required Friability Abrasive Characteristics Do you intend close circuit operation Capacity desired in tons per hour

...more

Frame Conveyor Idler

As we are acknowledged for providing high quality products to the clients, we make use of only superior grade raw materials as inputs. The selection of raw material is done by our experts. We provide customized packaging solutions, as we understand each customer is unique. The packaging we provide is strong, non-toxic, and capable of braving shipping and handling.

...more

Idler Rollers

In order to ensure zero-defect quality, we conduct several tests on the products prior to final dispatch. Assistance from skilled professionals and brilliant packaging unit has enabled us to meet specific requirements of the clients. Besides this, we make sure that the material used for wrapping them is of high quality.

...more

Vibrating Grizzly Screen

We have a good rapport with the prominent e-commerce merchants who provide us a secure payment gateway. With this, we guarantee instant and hassle free transactions. Our complete range of product is wrapped in strong, nontoxic, and superior-grade packs that protect the contents inside from damage, moisture, logistic movement, etc. Furthermore, the packaging has product details printed on it. Grizzly screens/Feeder are usually employed to extract coarse material from storage hoppers and convey it to downstream crushers. They are used for screening smaller grain size in the feed material which does not require crushing. Grizzly screens/Feeder are specially designed for such application. The Grizzly Screens/Feeder are Liner Motion & of bolted structure with a highly rigid design. The screen body consists of the two side plates with bolted transverse supports and screen mounts. The screen box is based on an open design. The Grizzly screen is supported above the substructure by means of helical coil compression springs. The screen installation angle can be varied to suit the application. The drive is through direct force exciter and Cardon shaft. The angle of throw is determined by the construction and application but usually 35 to 60 degree. The counterweights can be adjusted in stages from 50 to 100%. for variation of amplitude. There are several options for lubrication, oil or grease, which can be used without modification. Selected bearing seals ensure a long service life. Applications: Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite Minerals, Ores, Pellets, Sinter Sand and Gravel, building materials For Sizing and selection by our experienced engineering staff & to recommend the installation best suited to specific applications, answers to as many of the following questions as possible will result in a prompt and accurate solution to your screening requirements. Material to be screened Maximum feed dimension Approximate feed size analysis Moisture content Stickiness Bulk Density Separation sizes required Friability Abrasive characteristics Do you intend close circuit operation? Capacity desired in tons per hour

...more

Flip Flow Screen

Owing to our speedy distribution network, we are capable to render quickly and hassle free deliveries. The range, we offer, is stringently checked for the raw material used; our quality auditors ensure that the final product is sternly designed using the beat in class inputs to bring forth quality range. Details Flow Screen are used for separation of small cut size with good amount of moisture content which needs very high G force ( about 50 to 60 times G) for good separation and efficiency more than 90 % consistently. Flip Flow Vibrating Screen is used to separate fines with high moisture and sticky nature where the circular motion conventional mechanical vibrating screen becomes inadequate to cater the requirement. Damp and sticky materials are blinding over the apertures of the screen panel causing choking of the material on screen deck. Flip Screens are best suitable machines for separation of fines i.e particle size to be separated less then 15mm with high moisture content. The characteristic feature of Flip Flow Screen machines are two screen cases, one encased and the other which are counter currently oscillated by eccentric shaft. The screening takes place on permanently elastic highly wear resistant Polyurethane panels . Due to the counter motion of the screen, the screen panels are alternately, de-tensioned and tensioned in a defined manner about 600 times per minute which is 20 times higher than those of conventional screening machines Moreover , the elastic screen panel is not only tensioned but additionally stretched up to 10mm Hence the shape of the aperture is slightly changed and pegging of apertures by near size particles is prevented. . This leads to the characteristic, trampoline – like motion of the screening element. The screen normally works under acceleration force of about 50 g to prevent any type of clogging as against conventional screen which works at acceleration value of about 4 to 5 g. The construction of Flip-Flow Screen consists of two cases. The outer case and Inner case. The outer screen frame is suspended from the inner frame by guide springs, permitting horizontal movement. The inner frame is supported on the wedge shaped jack by means of Rubber insulating springs. The cross beams supported the polyurethane mats are alternatively connected to the inner and outer cross beams. The whole systems are counter currently oscillated by the eccentric shaft. The drive box of screen consists of eccentric shaft with a pair of eccentric bearing. The circular motion of the drive shaft is transformed into oscillation of the screen frame by means of thrust rod springs. Helical springs are arranged between the inner screen frame and the support jack thus ensuring that the machine is kept in the correct position according to the angle of inclination. The screen should have fixed cover on top to prevent dust. The screen should have provision of removal of individual sections of the cover to give easy access for easy maintenance. Applications: Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite Minerals, Ores, Pellets, Sinter Sand and Gravel, building materials Chemical Products, Fertilizers Compost, Refuse, Refuse Slags

...more

double roll crushers

We are counted amidst the well-known names involved in providing quality products from Asansol(India).We team makes sure that all the trade transactions are made keeping all the details of the clients confidential. Function Ajmani manufactures the double roller crushers separate the feed material with high pressure. The driven toothed rollers draw the material into the crushing gap. Due to the high impact rate of the circulating crushing tooth segments the effective crushing action starts already above the toothed roller. Design Welded robust housing Roller core shaped as a polygon with surface-ground supports for the crushing tooth segments Locking of the segments by means of dovetail guides and fastening by screwed bolts Tooth shape and tooth pitch are adapted to the respective application Crushing tooth segments individually replaceable without lifting the crushing roller out Crushing roller alternatively available with crushing rings Stationary and loose rollers with dust light encapsulated anti-friction bearing Stepless setting of crushing gap with optional mechanical or hydraulic overload protection Parallel evasion of the loose roller on the occurance of uncrushed components of the material Fields of application Cement,gypsum and limestone plants Coal,ore and potash mining Building,glass and chemical industries Metallurgical plants Advantages Compact design Simple Maintenance High throughput Preserving crushing action Low undersize shares Scarcely any dust accurrence To enable our experienced engineering staff to recommend the installation best suited to specific applications,answers to as many of the following questions as possible will result in a prompt and accurate solution to your screening requirements Material to be crushed Maximum feed dimension Approximate feed size analysis Moisture content Stickiness Bulk Density Product sizes required Friability Abrasive Characteristics Do you intend close circuit operation Capacity desired in tons per hour

...more

Circular Motion Screen

For the attainment of the complete clients' credibility, we issue an invoice to them including all the relevant information regarding products as well as agreed price. Our complete range of product is wrapped in strong, nontoxic, and superior-grade packs that protect the contents inside from damage, moisture, logistic movement, etc. Furthermore, the packaging has product details printed on it. Details Circular motion screen has two Fabricated Side frames made of mild steel duly stiffened adequately and bolted to deck frame on which screening mesh rests . Depending up on the type of screening cloth/ plate their bolting & side crimping is used. These screens are run by V- Belts & Pulleys or Cordon shaft coupled to Electric Motor of appropriate Kw. and RPM. Screen shaft is passed through the C.G of the screen and unbalance weights are mounted on shaft to provide desired amplitude to the screen . These unbalance weights are adjustable and can be increased or decreased according to requirement . Complete screen rest on adequate numbers of springs housed in mounting brackets bolted to screen side frames . Quantity & Size of the Springs are designed to suit the screen size and duty conditions. When Motor is run , circular motion of the motor is transmitted by help of V-Belts and pulleys or cardon shaft to screen shaft . Unbalance weights on the shaft provides the stroke to the screen which is double the amplitude. The Circular Motion Screens are Single , Double or Triple deck structure with a substantially rigid design. The screen body consists of the two side plates with bolted transverse supports and screen mounts. The screen box is based on an open design. The vibrating screen is supported above the substructure by means of helical coil compression springs. The screen installation angle can be varied to suit the application. The Drive shaft with its eccentric weights runs in heavy Screen duty self-aligning roller bearings. The throw of the vibrating screen is changed by adjusting the eccentric weights. The drive is either direct or through cardon shaft and v-belts. There are several options for lubrication, oil or grease, which can be used without modification. Selected bearing seals ensure a long service life. Applications:With single or multiple screen decks. Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite Minerals, Ores, Pellets, Sinter Sand and Gravel, building materials Chemical Products, Fertilizers

...more

Aury Vibrating Screen

We take care of all the raw materials used in the product manufacturing and designing. The inputs (raw material) used are quality certified and are remarkable for the production. In our well-constructed warehouse, we store the entire lot under safe conditions and away from various damaging factors such as direct sunlight, moisture, dust, rain and others. PUSHING LIMITS SETTING THE STANDARD Aury Tianjin China is an associate company of the DaDi Group,which is the largest privately-owned design and construction coal group in China.Made up of a dedicated team of professionals,the company has set out to provide the best screening and vidrating equipment into Australasia and the Pacific. Following world’s best practice, using proven design, Aury Tianjin China takes advantage of the economies provided by the large scale Chinese production,with the aid of technical know-how developed in Australia. Our team has sound research and design capability, backed up by technical expertise of a number of engineers who have been working with vibration technology with leading edge thinking and design techniques to produce capital equipment that is superior to anything found in the market today. FULLY –integrated production Unlike many other capital equipment manufacturers,Aury’s production facility is fully-integrated. All components like exciters , cross beams and exciter beams, all machined and fabricated in our Tianjin facility and assembled in our factory in Sebenza. Our principal production facility in Tianjin covers over 17,000 square meters under roof. We have a highly advanced CNC machining centre, large in-floor CNC milling/boring machine, highly specialized three coordinates measuring machine,as well as a workshop and a wide range of machining equipment,both large and small. Worldwide sales centred in Australia The application and technology for our equipment has been developed in Australia. It is for this reason that sales effort outside of China will be based in Australia and sales for Africa based in South Africa. Aury (Tianjin will service the China market.)

...more

Vibrating Screening Machine

Roll Crusher

Fabrication Works

Ours is an Asansol (West Bengal, India) based organization that is involved in offering reliable fabrication works. We conduct the fabrication work using the advanced machines and techniques. We have a team of reliable personnel, who are experienced in the domain of fabrication work. Moreover, we fabricate according to the specific requirements of the clients. Thus, we ensure complete satisfaction. In addition to this, our services are professional and nominally charged.

...moreOpening Hours