GSM Round Cutter Machine

4,500 - 5,500 Per piece

10 Piece (MOQ)

24-D Lint Cleaner Machine

Get Price Quote

1 Piece (MOQ)

The BAJAJ CONEAGLE Golden Eagle 24 – D Lint Cleaner produces the highest capacity and grade of any lint cleaner in the industry. Without sacrificing quality or turn-out. The BAJAJ CONEAGLE 24-D Golden Eagle Lint Cleaner is a saw-type, controlled-batt lint cleaner having two main assemblies, the lint cleaner base and the condenser assembly mounted on top of the lint cleaner base. One optional three-phase AC motor powers all drives in the condenser and lint cleaner. Major components of the condenser assembly consist of a 24-inch diameter perforated screen condenser drum and two grooved doffing rollers. Each end of the condenser drum is connected to an air duct. Air carrying cotton into the drum escapes out the air ducts while the cotton adheres to the drum. Adjustable flapper values on the ducts provide air balance. Major components of the lint cleaner base assembly consist of three feed rollers, a feed bar, eight cleaning grid bars, a saw cylinder and the doffing brush. Adjustments are provided for maintaining proper position of the components. Single or Tandem The BAJAJ CONEAGLE Golden Eagle 24-D’s are easily installed in single unit or tandem arrangements behind any gin stand and will more than meet every challenge. Valve configuration allows use of either, neither or both lint cleaners. Flow of Cotton Lint enters the condenser and is formed into a batt on the condenser screen. Air carrying the lint passes through the screen on the drum and exits out the two end ducts. The two grooved doffing rollers remove the batt from the condenser and direct it to feed rollers in the lint cleaner. The rear grooved doffing roller is installed with a minimum running clearance from the drum and allows the doffing rollers to form a pressure seat at the discharge point. The front doffing roller is set at 3/8 inch from the condenser drum. As the flow continues, the increased speed of the rollers draw and straighten fibers for the saw. Rollers draw and direct the batt to the feed rollers and the feed bar which feeds the batt into the saw. The feed roller is under spring tension exerting a force toward the face of the feed bar. The feed roller and feed bar grip the batt so that the fibers are drawn and combed as they are placed on the surface of the saw. Trash and mote particles thrown to the outside edge of the cotton by centrifugal force are stripped by the cleaning grid bars. The saw carries the cotton to the doffing point where it is removed by the brush. The brush also generates air flow to help convey the lint. Super Capacity and Cleaning 102” length handles all high capacity gins. Super-effcient 24″ diameter condenser 8 Precision machined and polished grid bars. Fine adjustment for top grade cleaning Precision engineered feed mechanism for optimum combing action Time-proven brush doffing Lock-out controls are standard equipment Rugged, Trouble-Free Construction Precision machined feed plate, adjustable for accurate placement, heavily built to hold critical settings Exclusive concave grid bar design further straightens and aligns fibers for high trash removal with reduced lint loss Exclusive tooth design on wire-wrapped saw insured superior lint retention, easier doffing Heavy steel shafts on sealed bearings Easily-removed components

Best Deals from Fabric Cutters

Gsm Round Cutter

5,000 - 6,000 Per Piece

1 Pieces (MOQ)

Gsm Round Cutter

3,500 - 4,444 Per Piece

1 Piece (MOQ)

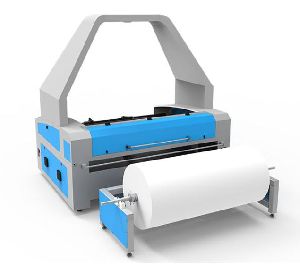

Textile Laser Engraving and Cutting Machine

Get Price Quote

1 piece (MOQ)

GSM Round Cutter Machine

Get Price Quote

1 Piece (MOQ)

Fabric Cutting Machine

2,800 Per Piece

1 Piece(s) (MOQ)

Band Knife Splitting Machine

Get Price Quote

Gsm Round Cutter

2 Per Piece

1 Piece (MOQ)

The GMS Round cutter is used to determine GSM (Grams per square meter) of the fabric (Woven Non-woven or knitted) and paper, film, foam, carper and board. The main body of the Round Cutter is made of fine quality aluminum casting for lightweight and resilience. Specifications Main body is made of fine quality aluminum casting for light weight and resilience Diameter of sample cut is 113 mm Catch lock is provided for safety.

Automatic Laser Cloth Cutting Machine

Get Price Quote

1 Piece (MOQ)

Rotary cut off cutters

3,000 - 5,000 Per pcs

50 Piece (MOQ)

We are a Supplier of Rotary cut off/coc cutters, made from the best quality raw material and available in various profiles as per customer requirement. The cutters are used for cutting all types of round metal including brass, copper, steel, aluminum, stainless, and titanium. Rotary cutters cut the material through displacing therefore it results in a chipless cut. The cutters are exported to various countries worldwide. The Rotary Knife is a common industrial application, used to cut a web of material in to smaller lengths, without stopping the line. These are manufactured close tolerances, enabling quick and easy setting. It is designed to provide you with proper dimensional integrity and tracking to produce a longer run and a cleaner cut.

Fabric Co2 Laser Engraving & Cutting Machine

320,000 - 450,000 Per Piece

1 Piece (MOQ)

Imported Round Card Cutter (upto 3inch)

4,500 Per piece

Imported Round Card Cutter Punch - ManualSize - 35/42/54/68/85mmPaper Type - PVCAction - Hand Operated+18% TAX EXTRA ON MACHINE

Coil Slitting Machine

4,400,000 Per Piece

1 Piece (MOQ)

Fabric Sample Swatch Cutter

Get Price Quote

Details : Hand operated swatch and sample cutting machine. Suitable for small number of samples. Designed for textile samples with serrated or straight edges. Precise and accurate thanks to right angle guide with millimeter graduation. Easy to operate, very handy. Reliable and maintenance-free. Comes with an operations manual. Unmatched price.

Steri Gauze Cutting Machine

Get Price Quote

1 piece (MOQ)

Manual Cloth Cutting Machine

4,500 Per Piece

1 Piece (MOQ)

Tespa IPG T9 Swing Arm Gauge

120,000 - 135,000 Per piece

1 piece (MOQ)

Consisting of Electronic Controller with Digital of Least count 0.001mm having Three Control output for coarse feed, fine feed and to finish controls. The measuring head is a Swing Arm Type with LVDT Transducers including Inter Changeable Caliper for diameters from 7mm to 65mm OR 65mm to 125mm with Diamond contact points, with Dashpot Assembly for Mounting the measuring head to the machine

Auto Rotary Reel to Sheet Cutter

Get Price Quote

Ultrasonic Fabric Cutting machine

Get Price Quote

1 Piece (MOQ)

35Khz Ultrasonic Fabric Cutting MachineFeatures and Function Real time frequency automatic tracking display Welding modes: time, energy, and grounding. Amplitude division function Welding amplitude 10%-100% adjustable (1% accuracy) Amplitude compensation Mold impedance analysis + protection Overload protection Voltage protection (input) Transducer voltage protection 485 communication