Used Kitchenware

It also gives lower productivity, dependence on skilled labour and quality issues. Semi-automatic polishing machines effectively addressed these issues. The variety of cookware is very large, the shapes and sizes are different. India makes a large volume of Aluminium pressure cookers, stainless steel kitchenware, stainless steel tableware, non-stick and hard anodized cookware etc. This is manufactured by very big companies brands like TTK, Nirlep, Hawkins, Butterfly as well as small and very small companies located in various areas. The level of automation demanded by these varied companies is different from each other. To address this variety effectively, a very wide range (around 15) of semi-automatic-machines and robust flexible and modular Automatic machines (around 6 varieties) were developed.

...more

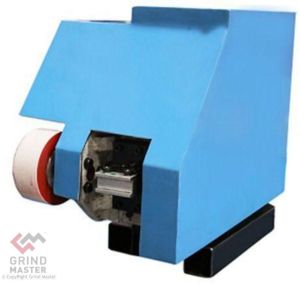

Tube Polishing Machine

We are offing tube polishing machine, grind master offers automatic centreless belt grinding & finishing machines for belt grinding, bright finishing and satin finishing of round tubes and pipes. The machine has very easy settings to ensure quick change over from one job size to another. The floating belt grinding heads are specially designed to take care of bend and ovality in tubes. up to 10 heads are offered. automatic loader unloader is offered as optional. Machines are designed for dry grinding as well as wet finishing. a wide range of consumables like abrasive belts, flap wheels, non-woven wheels, sisal and cotton buffs can be used in predetermined sequence for achieving the desired finish most economically. Tube up to 220 mm diameter can be finished. Machine can be offered with auto tube size setting which requires only 2 to 5 min. For setting the machine.

...more

surface finishing machine

Grind Master is the Metal Finishing Expert, offering the widest range of Metal Finishing Machinery for applications ranging across round tubes and bars, square tubes and flat bars, cookware, pots and pans, hardware, to roll grinding. We offer versatile and robust manual machines, as well as fully automatic Special Purpose machines for high volume production. The applications of machines vary from rough grinding to fine finishing. Our machines are used for Decorative Finishing purpose, whether buffing or polishing or finishing, are designed to yield optimum results. With experience of over 30 years in Metal Finishing field, we ensure the right products and processes are used for the various applications, yielding value addition and desired results for our customers.

...more

Superfinishing Attachment for Cnc Lathe

Grind master offers a very compact microfinishing attachment which can be mounted on tool post of a cnc lathe. it can be used with superfinishing films tapes as well as stones. finishes up to 0.04 micron ra can be achieved by using this attachment after turning or grinding process. the biggest advantage of superfinishing with films tapes is the consistency in the finish values achieved. this attachment has inbuilt slide which is pneumatically operated and thus the attachment can be retracted after superfinishing process automatically. due to very compact size and 40 kg. Weight, when mounted on tool post of a lathe, it does not create over hang loads. It is used for superfinishing various step diameters of engine and transmission shafts.

...more

Stainless Steel Flat Bar Grinding Machine

Grind master offers conveyorised belt grinding machine for descaling, finishing of ss flat bars, hex bars, square bars. the machine has unique floating type belt grinding heads to ensure uniform grinding quality. the machine is provided with sophisticated features like motorized head adjustment, digital read out for the head position, pneumatic belt tensioning, return conveyor system, inlet, outlet conveyors etc. the machine can be offered with one head up to 4 belt heads and for dry grinding or wet grinding.

...more

sheet metal equipment

Modern development of high quality equipments demand high quality aesthetic as well as engineered metal finish. Unfortunately most of the manufacturing & fabrication processes produce parts with unsatisfactory surface finish. As industry tries harder to approach the perfection in metal finish, interest has focussed more closely than ever before on metal finishing processes such as polishing, belt grinding. It not only helps improve aesthetic finish but also drastically improves corrosion resistance, wear resistance, material hygiene, etc.

...more

S p m machine

Grind Master offers wide range of custom built metal finishing machines for finishing of mass manufactured odd shaped components. Being the metal finishing & machine building expert, we know the right process and right tools to finish odd critical jobs. We ensure that the machines exceed our customer’s expectations in terms of productivity as well as quality.

...more

Rotary Indexing Polishing Machine

we are offering Pressure Cookers, Grind master offers 6 8 10 station rotary indexing machines for high volume production of cookers, pots and lids. the machine uses imported rotary indexing table and 4 to 9 polishing heads. we have various types of polishing heads and they are selected based on the job requirements. all the heads are provided with auto wheel wear compensation and auto polishing compound spray system. the job holding is by vacuum and the job drive is through rugged chain drive mechanism. the machine is used for external bright finishing of aluminum and stainless steel pots and pans, lids, cookers etc. it can polish 100 to 300 jobs per hour.

...more

Packaging Paper Tubes

Printing And Packaging is a fast developing industry, both in quantity as well as quality. Various Rolls, Cylinders and Tubes are used in Machinery for PrintingPackaging that require specific Engineered Finishing results. Grind Master has developed specific solutions for various applications in this industry.

...more

MICROFINISHING FILMS

23,000 Per Piece

Following grit sizes available for respective abrasive series. Kindly select the appropriate grit size & belt size accordingly.

...more

metal polishing machine

Modern development of high quality equipments demand high quality aesthetic as well as engineered metal finish. Unfortunately most of the manufacturing & fabrication processes produce parts with unsatisfactory surface finish. As industry tries harder to approach the perfection in metal finish, interest has focussed more closely than ever before on metal finishing processes such as polishing, belt grinding. It not only helps improve aesthetic finish but also drastically improves corrosion resistance, wear resistance, material hygiene, etc.

...more

metal polishing bars

A wide range of Centerless Belt Grinding and Polishing Machines is used for round tubes and bars. A complementary range of machines for square tubes and flat bars covers the other requirements for Tubemill and other requirements. Further Sheet Grinding and Polishing systems from Thin Strips to wide sheets (in representation of Timesavers, Holland) completes the product range. With over 2000 machines in operation in the Metal Industry, Grind Master is a reliable partner to its customers. Round Bars

...more

Metal Polish

Grind Master’s exclusive sheet metal finishing range of machines offer complete solution for sheet coil finishing applications. These machines are built to be accommodated in production line of sheet coil manufacturing plants. Various laser plasma water jet cut profiles can be finished in uniform manner.

...more

Metal Grinding Machine

Metal Industry including Advanced Metals such as Titanium and Nickel Alloy require Deburring of Sheets and Flat Surfaces on the edges.Grind Master Sheet Metal Deburring solutions consists of :CFG series Machines Designed and manufactured by Grind Master, TGM series Machines under Technical Collaboration with Timesavers.

...more

metal finishing machine

Grind Master is the Metal Finishing Expert, offering the widest range of Metal Finishing Machinery for applications ranging across round tubes and bars, square tubes and flat bars, cookware, pots and pans, hardware, to roll grinding. We offer versatile and robust manual machines, as well as fully automatic Special Purpose machines for high volume production. The applications of machines vary from rough grinding to fine finishing. Our machines are used for Decorative Finishing purpose, whether buffing or polishing or finishing, are designed to yield optimum results.

...more

metal cookware

It also gives lower productivity, dependence on skilled labour and quality issues. Semi-automatic polishing machines effectively addressed these issues. The variety of cookware is very large, the shapes and sizes are different. India makes a large volume of Aluminium pressure cookers, stainless steel kitchenware, stainless steel tableware, non-stick and hard anodized cookware etc. This is manufactured by very big companies brands like TTK, Nirlep, Hawkins, Butterfly as well as small and very small companies located in various areas. The level of automation demanded by these varied companies is different from each other. To address this variety effectively, a very wide range (around 15) of semi-automatic-machines and robust flexible and modular Automatic machines (around 6 varieties) were developed. These machines were developed from scratch and now Grind Master has full range of semi-automatic & fully automatic machines for polishing cookware. With over 500no.s of machines in the market, and being a pioneer in the field, it can be said that Grind Master has brought a transformation into the Cookware Polishing Industry.

...more

Grinding Belts

Coated Abrasive Belts for various achieving Stock Removal (Grinding) and Surface TextureFinish (Finishing) requirements:Flat Surface Grinding of steel, non-ferrous metals, wood, composites & solid surface materials Cylindrical Grinding of wires, tubes, etc.Off-Hand Grinding using held grinding, power tools, backstands, etc.Robotic Grinding.

...more

Gear Tooth Chamfering Deburring Machine

Grind master offers Gear Tooth Chamfering and Deburring Machine in Technical Collaboration with SAMPUTENSILI, Italy. Model SCT3 is a universal machine which can be used for a wide range of spur and helical gears, shaft type gears, bevel gears and pinions etc. It has Chamfering and Deburring heads that use patented tooling from SAMP so as to produce symmetrical & consistent chamfering results on the gear tooth. SAMP patented deburring tools are spring loaded to compensate for face width variation. The machines are offered with optional shuttle feed loader or gantry robotic automation systems.

...more

gear deburring machine

As industry is striving for high speed, highly productive and efficient machines, the components going in these machines need to be highly precise. Residual burr in such assemblies may result in malfunctioning of machine which in-turn would result in loss in productivity and efficiency. Deburring process ensures removal of even minute secondary burr from the component which results in smooth & extended product life. Deburring has over the years become a Critical Operation for Many components. Deburring a part satisfactorily and consistently requires a large experience of various deburring methods and tools. The amount of burr created by every metal cutting process is different in nature, and varies with the material, hardness, and sharpness of the cutting toolsdies.

...more

Frp Tubes

With new developments in engineering & manufacturing industry, surface finishing need is vastly needed for various applications. Be it engineered finish or aesthetic finish, Grind Master gives exact solution for both the requirements. Apart from metal tube finishing, we are also expert in delivering solution for different variety of tubes like FRP Tube, Paper Cores etc. Rotogravure cylinder superfinishing is one of the critical operation for which Grind Master offers dedicated solution as per application need. Grind Master in association with Epistolio Italy provides unique solution for painting application with self-learning robotic technology.

...more

Fettling Machine

Robotic Iron Casting Fettling is revolutionary solution for Iron Foundries. Fettling is major bottle neck for foundries. Most of the foundries till now were doing fettling work manually. It is time consuming process as well as very hazardous for the workers’ health. With automation replacing manual process, foundries are achieving better productivity along with consistency in output.

Feature : Rugged Machine Build, Automatic Path Correction for Variations in Casting, Maximum Fettling Performance.

...more

deburring tool

deburring equipment

the manufacturing & fabrication processes produce undesired Burr.As industry is striving for high speed, highly productive and efficient machines, the components going in these machines need to be highly precise. Residual burr in such assemblies may result in malfunctioning of machine which in-turn would result in loss in productivity and efficiency. Deburring process ensures removal of even minute secondary burr from the component which results in smooth & extended product life. Deburring has over the years become a Critical Operation for Many components. Deburring a part satisfactorily and consistently requires a large experience of various deburring methods and tools. The amount of burr created by every metal cutting process is different in nature, and varies with the material, hardness, and sharpness of the cutting toolsdies.

...more

Crankshaft / Camshaft Lapping Machine

We are offering crankshaft camshaft lapping machine. Grind master offers crankshaft and camshaft microfinishing machines in technical collaboration with impco usa. The machines are built with patented gbq (generating bearing quality) technology. The machine configuration is determined depending upon the part drawings, cycle time requirement etc. These machines are capable of producing a surface finish of 0.12 �µra from input of 0.4�µra in a single step, consistently, with improvements in geometry, size-control & taper. auto loadingunloading, interface with gantry etc. Can be offered as extra feature. microfinishing of engine parts by gbq method extends product life, prevents premature bearing failure thus reducing warranty cost. For details please contact with job drawings. For further information please contact us â��

...more

Robotic Automation Solutions

Grind master automation division has successfully built sophisticated automation solutions with robots, gantry systems and customized manipulators. Grind master “hi-tech” automation group makes hitherto impossible to automate tasks possible. We understand the requirements of the customer, as well as the engineering needed to make a reliable, robust automation solution. Our range of robotic applications include metal finishing, deburring, handling, pouring and fettling amongst others. robotic applications the range of solutions offered includes : robotic metal finishing robotic deburring robotic tending handling on machines robotic pouring for aluminum die castings robotic fettling for aluminum and iron castings grind master expertise in processes of metal finishing and deburring. turnkey automatic lines grind master offers turnkey automated lines and solutions for high volume production. With our expertise in trimming and beading, oval cutting circle cutting, polishing, riveting and automation, grind master is your partner for a full solution for automatic cookware production system. With expertise in robotic applications, crankshaft polishing and dynamic balancing, grind master is your partner for automotive production lines. grind master also provides consultancy for automation.

...more

Polishing Machines

Be first to Rate

Rate This