Table Fan Stampings

The clients can contact us for purchasing a high quality auto-stitched & auto-skewed motor stampings for table fans, which are designed using cutting-edge technology including high speed stamping lines and ultra precise carbide progressive tools.

...more

T200 Cooler Kit Stamping

Kumar Precision Stampings Pvt. Ltd. specializes in the manufacturing of T200 Cooler Kit Stamping in three different models. All three models vary in bore sizes, which range from 12.7 to 16.

Diameter : 110 Dia

Material : Aluminium

...more

Mixer Stampings

Our clients can avail from us high quality auto-stitched mixer motor stampings manufactured using highest quality raw-material. The motor stamping for mixers provided by us are also acclaimed for features like high efficiency and precision engineered design. Moreover, these products are also available in different customized versions, so as to meet the particular requirements of the clients.

...more18" Exhaust Fan Stamping

We are an eminent manufacturer of 18" Exhaust Fan Stamping. Manufactured with ultra-modern Hiperm technology, our 18" Exhaust Fan Stamping renders excellent performance year after years.

Diameter : 15 -1200 mm

Shape : Round

Material : CRCA Coils

...more15" & 12" Exhaust Fan Stamping

You can avail 15" & 12" Exhaust Fan Stamping, a technologically sound product, from Kumar Precision Stampings Pvt. Ltd. Our 15" & 12" Exhaust Fan Stamping is exclusively praised for its longevity and performance.

Condition : New

Material : SS, MS, CI

Shape : Round

...more

Hiperm Stator

Kumar Precision Stampings Pvt. Ltd. is a trusted manufacturer of Hiperm Stator. We use Hiperm Technology with state-of-the-art facility for Annealing. Process Hiperm Technology is an advanced process for the production of Hiperm Stator that reduces the Watt Loss. This process is carried out by giving heat treatment to stampings to reduce the Carbon Percentage and develop a uniform grain structure. Hiperm – A Technology Par Excellence The process results in the reduction of carbon percentage & core loss, improves grain size structure and desired coating thickness on stampings as a result of decarburizing & bluing of low carbon CRC are tested on specified instruments required for the purpose. This process results in reduced watt losses, which ultimately benefits Fan Manufacturers in terms of increased efficiency of the products. The stampings manufactured at the end confirms a core loss of 5.5 to 6 watts per K.guass at 1.5 Tesla at 50 cycles/sec. The company offers customized Hiperm Stators as per the needs of top-notch Fan Manufacturers. Why Kumar Precision Stampings Pvt. Ltd.? Usage of modern Hiperm Technology having advantages like :Reduction of watt lossReduction of Carbon percentageDevelopment of uniform grain structureGetting desired coating thickness on stampingsAn expert team of qualified personnelFocus on innovationFlawless quality from start-to-finishAdds efficiency to the end product We can entertain all kinds of requirements for Hiperm Stator. Just fill the below mentioned enquiry form and specify your requirements in detail, so that we can serve you better & promptly.

...more

Electrical Stampings

We are offering electrical stampings. We efficiently cater to lamination requirements of its clients with the help of a number of high speed presses varying from 100 ton to 300 ton with speeds up to 400 spm for lamination punching. Our fully automatic stamping lines are imported from one the biggest and most professional mechanical press machine manufacturers in china and are equipped with auto-skewing & auto stacking controllers , high tech de-coilers, s-type material straightener & geared feeders for running ultra-precise progressive tools. the company has a variety of ultra-precise carbide progressive lamination stamping tools for various motor cores, capable of manufacturing auto-stitched & auto-skewed cores and operating at high speeds. to guarantee tools with highest precision, long life and great stability, we have ties ups with the biggest & most professional progressive tool manufacturers in china who have the best of the equipments & infrastructure to produce the most precise tools as per our customer’s requirements.

...more

Cooler Stampings

Kumar precision stampings pvt. Ltd. Is a name that you can rely upon for cooler motor stampings. Our auto-stitched & auto-skewed cooler motor stampings are manufactured using optimum quality raw materials and state of the art technology, thus assuring for highest performance.

...more

ceiling fan stampings

Leveraging the power of high speed presses and ultra-precise carbide tools, the company has been offering auto-stitched and auto-skewed ceiling fan stampings to various leading brands. The company offers customized ceiling fan electrical stampings as per the needs of leading ceiling fan manufacturers.

...more

Ceiling Fan Stamping - Fc 116

Kumar Precision Stampings Pvt. Ltd. is one stop destination for optimum quality Ceiling Fan Stamping FC 116. In addition to standard sizes, we also manufacture Customized Ceiling Fan Stamping FC 116 as per the requirements of clients.

Application : Electrical motor industries

Shape : Circular

Material : Electrical grade steel

Diameter : 15 -1200 mm

...more

Ceiling Fan Stamping - FC 110

Kumar Precision Stampings Pvt. Ltd. specializes in the production of Ceiling Fan Stamping FC 110. Our Ceiling Fan Stamping FC 110 comes in two models and both the models have different slots in stators.

Shape : Round

Material : Silicon

Condition : New

...more

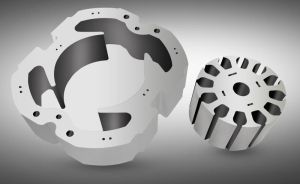

Aluminium Die Cast Rotors

Bridging the gap between the need and supply, the company has been rendering high quality Aluminium Die Cast Rotors. Technology, the Company Uses High capacity die casting machines with multi cavity tools are used to meet the bulk demands of the clients within the stipulated timeframe. Moreover, a large gamut of up-to-date In-Shelf Dies enables the company to offer unbeatable die casted rotors in various specifications. The Forte : Customization The company offers customized Aluminium Die Cast Rotor as per the needs of leading Ceiling Fan Manufacturers. Why Kumar Precision Stampings Pvt. Ltd.? An Experienced team Sound infrastructural base Uses quality raw materials with advanced techniques Focuses on maintaining the quality at every level of production Conducts strict quality tests using hi-tech testing equipment Maintains that every parameter is within the prescribed tolerance range We can entertain all kinds of requirements for Aluminium Die Cast Rotor. Just fill the below mentioned enquiry form and specify your requirements in detail, so that we can serve you better & promptly.

Type : Die Cast Rotors

Material : Aluminium

Diameter : 100-500mm

Application : Motor

Color : Brown, Pink

Feature : Fine Finished, Hard Structure

...more

Aluminium Die Cast Rotor

Bridging the gap between the need and supply, the company has been rendering high quality aluminium die cast rotors. Technology, the company uses high capacity die casting machines with multi cavity tools are used to meet the bulk demands of the clients within the stipulated timeframe. Moreover, a large gamut of up-to-date in-shelf dies enables the company to offer unbeatable die casted rotors in various specifications. customization the company offers customized aluminium die cast rotor as per the needs of leading ceiling fan manufacturers. Why kumar precision stampings pvt. Ltd.? an experienced teamsound infrastructural baseuses quality raw materials with advanced techniquesfocuses on maintaining the quality at every level of productionconducts strict quality tests using hi-tech testing equipmentmaintains that every parameter is within the prescribed tolerance range we can entertain all kinds of requirements for aluminium die cast rotor. Just fill the below mentioned enquiry form and specify your requirements in detail, so that we can serve you better & promptly.

...more

Ceiling Fan Stamping - FC 112

Ceiling Fan Stamping FC 112 is available in five different models and their bore sizes ranges from 14.30mm to 18.50mm. Our Ceiling Fan Stamping FC 112 is sure to render excellent performance even under severe conditions. To enquire more about the desired product(s), just check the box and then click �Send Inquiry� button which is provided below.

Material : Mild Steel

Color : Silver

Condition : New

Material : Stainless Steel

...more

Hiperm Stators

Kumar Precision Stampings Pvt. Ltd. is a trusted manufacturer of Hiperm Stator. We use Hiperm Technology with state-of-the-art facility for Annealing. Process Hiperm Technology is an advanced process for the production of Hiperm Stator that reduces the Watt Loss. This process is carried out by giving heat treatment to stampings to reduce the Carbon Percentage and develop a uniform grain structure. Hiperm � A Technology Par Excellence The process results in the reduction of carbon percentage & core loss, improves grain size structure and desired coating thickness on stampings as a result of decarburizing & bluing of low carbon CRC are tested on specified instruments required for the purpose. This process results in reduced watt losses, which ultimately benefits Fan Manufacturers in terms of increased efficiency of the products. The stampings manufactured at the end confirms a core loss of 5.5 to 6 watts per K.guass at 1.5 Tesla at 50 cycles/sec. The Forte : Customization The company offers customized Hiperm Stators as per the needs of top-notch Fan Manufacturers. Why Kumar Precision Stampings Pvt. Ltd.? Usage of modern Hiperm Technology having advantages like : Reduction of watt loss Reduction of Carbon percentage Development of uniform grain structure Getting desired coating thickness on stampings An expert team of qualified personnel Focus on innovation Flawless quality from start-to-finish Adds efficiency to the end product We can entertain all kinds of requirements for Hiperm Stator. Just fill the below mentioned enquiry form and specify your requirements in detail, so that we can serve you better & promptly.

Type : Stators

Shape : Round

Thickness : 0-1mm, 1-2mm

Application : Explosion Proof Motor, High Power Motor

Color : Shiny-silver

Finishing : Polished

...moreOpening Hours