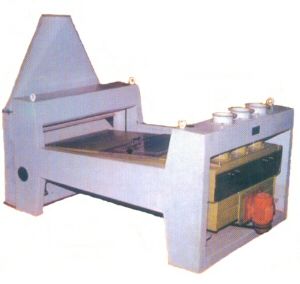

Vibro Seperator Type VTRA

The Vibro Seperator Type VTRA is one of the latest developments in grain cleaning by machinery. It can be used both as preliminary and secondary cleaning seperator. There being three controls (throw, stroke, inclination of sieve) the machine can be used in a large variety of applications such as rice, wheat, paddy, barley, maize, all pulses, groundnut and oilseeds like mustard, soyabean, sesame, sunflower etc. The main body of the machine has two decks of sieves - for renewal of both small and large impurities. The movement of stock along the sieve is brought about by the vibrating motion imparted by two vibrating devices at the feed end of the machine. Oversized and undersized impurities are taken through the spouts located at the side and bottom of the machine respectively. The cleaned stock comes at the tail end of the machine. Key Features Minimum maintenance, since moving parts in the machine are kept to the minimum. There is no other moving part except the vibrators. Angle of throw can be adjusted to suit the application at site. The stroke length can be adjusted as per requirment at site. Screen inclination is adjustable. It is pre set at works at 1.0 to 13.5. For special applications, continuous adjustable system for screen slope can be provided on request. Drive by means of double vibrators located at the feed end. Free moving sieve box supported on specially designed rubber section. Optional Additions Available Aspiration channel Type: VAC Special magnetic separator type: VSM

...more

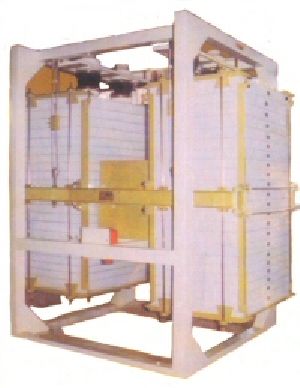

Versatile Plansifter

Versatile Plansifter Type VC & VCD are custom-designed and built for multi-purpose sifting operation. these are used in all types of granular and floury stocks. Some of their universal applications are: Rice Mill Products Tips and small brokens (Nakku/ Kinki) grading and sifting Precision sizing and for removal of immature grains from main rice Removal of thicker grains (choba) from main stock Sifting of rice rawa and powder Flour Milling : Flour redressing, break stocks, Atta redressing, Semolina and all mill stocks, grading of wheat screenings and by products. Grains : Grading of various types of grains, Pulses (Dals), Peas, Soyabean and various types of oil seeds. Spices : Separates, grades and sifts different types of spices such as Black pepper, Red Chillies, Zeera, Saunf, Ajwain, Satisabgol, Coconut Powder. Other Industries Included : Feed mill products, Sugar, Chemical & Pharmaceuticals, Plastics, pellets and powder, Starch, Potato Flour, Speciality food Products, Bakery and Confectionery, cocoa etc. Features The Versatile Plansifter incorporates completely new design made for the first time in India. Versatile Plansifter Type VC consists of two independent sections of sieves containg 10 to 12 sieve frames each which are able to handle two different stocks. Each section can provide two to four separations. Versatile Plansifter Type VCD consists of 4 independent sections of sieves containing 12 to 20 sieves frmes each which are able to handle four different stocks. Each section can provide two to eight separations. The entire machine is supported by a rigid square stell frame and is designed to mount the sifter on the floor. All sieve frames sieve housing and flow channels are fully laminated thus making the machine highly wear resistant which also meets criteria for durability and hygine.

...more

Scouring Machine Type: VSC

Highly efficient machine for removal of dirt deposited on cereal. Used in conjunction with specially designed aspiration channel. Functions Scouring is effected by a rigorous three step rubbing - grain with wire mesh scouring jacket, grain with grain and grain with beaters. The Grain which has to be treated is fed tangentially to the impact section of horizontal scouring jacket, in which the scouring rotor is also positioned. Key Features High scouring efficiency with least breakage. High capacity to power consumption ratio. Minimum maintenance Easy accessibility.

...more

roto sifter separator

The ROTO Sifter Separator is an innovation to grain cleaning machines and is used as a Preliminary or secondary clening separartor. It removes material that would cause undue wear and tear on subsequent machinery, ensures hygienic storage conditions and good quality garin, by thoroughly eliminating foreign cereals and impurities. The machine is suitable for cleaning Whea, Rice, Paddy, Soyabean, Barley, maize (Corn), Peas, various types of pulses and oil seed like Mustard, Sunflower, Sesame, groundnut etc. Key Features Three different speeds to suit different requirements. High throughput. Simple and low maintenance. Two adjustable balance weights to give variable throw or circle. Quiet and vibration-free operation. Low power consumption.

...more

Rice Milling Machine

No moving part except two bearings make the main machine tray almost maintenance free. Four different principles of separation employed for near total cleaning. No more dust near the machine for operator health and hygine as all the sieves and chamber are fully covered. Newely developed cyclochamber ensures very little escape of dust particles to the fan. Thus almost eliminating the use of cyclone in the system.

...more

Rice Mill Plant

High efficiency and high throughput due to rotary and linear motion No jerk on bearing, quiet and vibration free operation due to absolutely balanced drive ensures enhanced mega separator life. Latest technology ensures high speed operation up to 500rpm. Much lower power consumption compared to other similar machines. Six different impurities taken out from the grain flow. Unique design to accommodate Magnetic Separator for removal of Iron pieces both at tail end and inlet of the machine (optional). No moving part except two bearings make the main machine tray almost maintenance free. Four different principles of separation employed for near total cleaning.

...more

Rice Mill Machine

High efficiency and high throughput due to rotary and linear motion No jerk on bearing, quiet and vibration free operation due to absolutely balanced drive ensures enhanced mega separator life. Latest technology ensures high speed operation up to 500rpm. Much lower power consumption compared to other similar machines. Six different impurities taken out from the grain flow. Unique design to accommodate Magnetic Separator for removal of Iron pieces both at tail end and inlet of the machine (optional).

...more

PULSE JET FILTER

The VJF type pulse jet filters are designed for use in grain, cereal and food handling systems as well as in machine aspiration systems. It operates continously and automatically , the only moving parts are simple diaphram valves. Dust laden air is allowed to pass through fabric filters, thus separating the dust from the outgoing air. The filter sleeves are cleaned by intermittent pulse of compressed air, sleeves are fitted on metal cylindrical frames and suspended below nozzles. They are secured to their supported flanges by quick release clips, a features that reduces maintenance time. Designed for use in a Flour Mill as well as grain, cereal and food handling systems and cement industry. Dust laden air is allowed to pass through fabric filters thus separating dust from outgoing air. Key Features A full range of filter sizes . High air to cloth ratio capacity. Very low power requirments. Silicon chip timer control. Infrequent and simple maintenance.

...more

Plan Shifter Type-HPL

Type-HPL Plansifter is designed for sieving process in the Flour Milling Industry. It can also be used for grading purposes in other field of Industry. The machine consists of a vertical nest of horizontal sieves, the whole assembly gyrating in a horizontal plane. The ground stock is fed in the top and falls from sieve to sieve by gravity. Owing to movement of sieve, the stock resting on it becomes strarified, thus the finest Particles work down, whilst the largest ride upto the surface of the stock and tails out. Special Features The plansifter Type HPL represents the latest development in sifter design and technology. this Plansifter is a high capacity machine having square sieves. The range of its feed section is four and eight and can make upti=o eight separations per section. Each section can be further divided into two to give more flexibility of scheming. All sieve frames, sieve housinga nd Flow channel are fully laminated thus making the machine highly waer resistant which also meets all criteria for durability and hygine. The sifter can handle 30 to 40% higher capacity due to the adoption of latest production techniques.

...more

Paddy Separator

The Vashist Padyy Separator Type VPT is the machine designed for complete separation of Paddy from Brown Rice. Because of the physical weight and surface courseness of Paddy and Brown Rice, it is able to separate the Paddy and Brown Rice to almost 100% accuracy.

...more

Mega Separator

Key Features High efficiency and high throughput due to rotary and linear motion No jerk on bearing, quiet and vibration free operation due to absolutely balanced drive ensures enhanced life. Latest technology ensures high speed operation up to 500rpm. Much lower power consumption compared to other similar machines. Six different impurities taken out from the grain flow. Unique design to accommodate Magnetic Separator for removal of Iron pieces both at tail end and inlet of the machine (optional). No moving part except two bearings make the main machine tray almost maintenance free. Four different principles of separation employed for near total cleaning. No more dust near the machine for operator health and hygine as all the sieves and chamber are fully covered. Newely developed cyclochamber ensures very little escape of dust particles to the fan. Thus almost eliminating the use of cyclone in the system. Unintegrated fandesign ensures: Possibility of putting the fan after cyclone for more fan life & less maintenance. Use of sme fan for the aspiration of feed elevator shooting hopper and de-husker thus reducing capital cost and power consumption.

...more

indent cylinder

Vashist Indent Cylinder (Length Grader) is used in cleaning and grading various types of seeds and cereals. It separates shrivelled, immature and broken grains from whole grains by length. The machine is primarily a horizontal rotating cylinder made of a special carbon steel sheet with pressed indents. The material to be treated enters the machinethrough the feed hopper and is taken up by the indents of the rotating cylinder. The short and broken grains are lifted by the indents into the collecting tray. Longer grain tail out of indents and are passed to the delivery end. There is an indicator scale provided at the tail end of the cylinder which indicated the position of the collecting tray. The position of the tray can be adjusted by a hand wheel to achieve the best separation possible. Key Features The machine can be used in parallel or in series to obtain two or more separations from a single feed. The machine is such designed that the collecting tray can be inverted to clean the tray thoroughly and quickly. The indented cylinder has been made split to facilitate easy cleaning or cylinder change. To ensure double cylinder replacement life, compared to other locally available machines,the machine has been so designed that reversible indented cylinders can be turned , end for end when indents wear on one side. To prevent dust accumulation, the machine can be connected to an aspiration system. To offset the practical problems of noise and maintenance of variable speed devices a three step pulley drive device has been incorporated to achieve speed variations. Comparatively higher efficiency and capacity is achieved due to about 18% more indents in unit area of the indent cylinder when compared with oter machines available in the market. To keep the indent cylinder clean of any dirt accumulation, a newly developed brushing system with engagement and disengagement device has been incorporated.

...more

husk aspirator

maintained by pneumatic control system. An automatic sensing system at the feed inlet ensures that the rubber rolls are disengaged as soon as the flow of paddy is cut off for any reason. Thus ensuring longer rubber rool life. The degree of hulling is more compared to the conventional sheller. The mixture (brown rice, husk. paddy) thus produced is fed automatically to the hull aspirator separator to separate the hull from brown rice.

...more

Drum Sieve Machine

The primary aim of the Drum Sieve is to separate coarse impurities like straw, strings, stones, wood, paper, leaves etc from various cereals and grains in the intake section of the mill. The machine is suited to separate impurities such as Straw, String, Stone, Wood, Paper, leaves etc. . A specially designed aspiration hood removes majority of dust and light impurities. The machine helps to reduce the amount of wear and tear on the subsequent machinery in the cleaning section. It also helps in keeping the environment dust free.

...more

DRUM SIEVE

The primary aim of the Drum Sieve is to separate coarse impurities like straw, strings, stones, wood, paper, leaves etc from various cereals and grains in the intake section of the mill. The machine is suited to separate impurities such as Straw, String, Stone, Wood, Paper, leaves etc. . A specially designed aspiration hood removes majority of dust and light impurities. The machine helps to reduce the amount of wear and tear on the subsequent machinery in the cleaning section. It also helps in keeping the environment dust free. Key features: Less space requirements Low power requirments. High output. Solid design and negligible maintenance. Double operation (Scalping and Aspiration) The machine is all metal construction with side inspection doors. An aspiration hood (with regulating valve) is provided to aspirate the stock to ensure dust free operation. the speed of the drum is set in such a way that the gravity is more intense than the centrifugal force, that helps to achive the maximum efficiency of the machine. The grain to be cleaned passes through a specially designed feed roll over the revolving sieve drum of SS Wiremesh which is open at one end. The grain after passing through the sieve crosses through a strong air current in front of the said aspiraion hood. Thus dust and lighter impurities are taken away by the air current to the cyclone dust collector of the system to which the aspiration is connected. The cleaned grain is discharged through a hopper and the coarse impurities tail over to an outlet.

...more

Drum Detacher (Type VDD)

Detacher is a machine for breaking of the flaked fragments of the grind of the smooth roll passage in a flour mill. Its application will increase the efficiency of the sieving machine. It also helps reducing the load on the subsequent roller mills. A simply supported rotor having a beater and conveying blades is enclosed in a drum encloser. The stock enters at the top end and leaves the machine from the bottom end. The grind of the smooth roll enters through the inlet hopper. It is thrashed against the walls several times by the action of beaters before reaching the discharge spout. Thus all the flakes present in the incoming stock get fragmented and dislodged.

...more

Double Aspirator

Fabricated CRCS Sheet construction. Compact Design Minimal maintenance. Operation The product enters the macine through feed spout on top (center) of the machine and is spread in a thin layer.Aspiration hoods are connected to a central aspiration system. Thus flowing air passes through this layer of falling grains carrying all light impurities from the product. The clean stock is collected at the bottom of the machine and passes through the connected spout.

...more

De-Stoner Cum Classifier

The machine combines two major functions simultaneously. It concentrates impurities and separate stones and other heavy impurities from the grain. The machine has unique high separation efficiency because of its design. It divides the grain into two fractions light nd heavy before separating stones from the heavy. The machine is suitable for destoning and grading of Wheat, Rice Paddy, Barely, Cocoa, Rye, Maize (Corn), Hazlnuts, Soyabean, Peas, Bajra, Gowar and Pulses and various types of seeds like Sesame, Cottonseed, Mustard, Sunflower, Groundnut and various types of spices. Operations. The De-stoner Cum Classifier consists of two decks enclosed in special steel frame body supported by springsystem and telescopic rod. The machine is provided with large inspection area for monitoring. The outlets in the front of the machine body are for heavy and light fractions and two outlet at the rear for stones. two vibrator motor impart linear motion to the double deck frame. The product inlet feed device is fitted with automatic discharge flap which insures continous distribution on to the top deck screen. Flexible exhaust ducting is connected with micrometric adjustment butterfly valve. Grain entering the machine spreads over the entire width of the top screen deck where it is stratified. the heavier fraction passes through the top screen and falls on the stoning deck which peforms stoning through oscillating action and fluidising air stream. Stones and other material of higher density are thus throughly removed from grain stream. Light fraction of concentrated impurities moves forward suspended in air towards the outlet of the top deck. The concentration of fraction canbe alerted either by exhaust air or by changing screens. Different sizes of sieve screens can be provided to meet the requirement of different products in large number of industries.

...more

Bucket Elevator

A Bucket Elevator is an endless rubber coated or cotton belting to which equally spaced buckets are attached, which elevates material and discharges the contents of the buckets at the top into a spout or other receiver. Elevators are usually vertical. KEY FEATURES Vashist Elevators are slow speed to helps make it brakage free. Near zero back legging, helps make it brakage free also. High efficiency, saves so much power that the elevator becomes free in few years. High capacity, upto 100 tonne per hour. Both MS and SS-304 construction available. Heavy duty construction such that more than 100 feet height is possible. Easy to clean & maintain. Back stop arrangement provided to stop reverse rotation of belt. Elevators can be made to suit specific requirements depending on capacity required, height and type of material to be handled.

...more

Bran Finishers (Type VBF)

The VBF type Bran finishers are designed to separate the last remaining endosperm adhering to the bran to ensure maximum flour extraction without causing excessive bran contamination. Operation The stock enters the machine tangentially, at the inlet. the stocks are thrown against an impact wall and perforated screen by internal crimped beaters rotating inside. The continous impact caused by these beaters separates the last remaining endosperm from the bran particles while the bran itself is not excessively damaged. The released endosperm then passes through the perforated screen jacket, to be collected for further processing and the cleaned bran comes out of the tail end of the the machine. Key Features Increased extraction - recovery of valuable endosperm. High capacity - with efficient endosperm recovery. Low power and space requirments. Robust, long-lasting, hygienic construction.

...moreBe first to Rate

Rate ThisOpening Hours