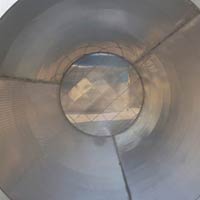

Self Cleaning Blade Centrifugal Blower

24,500 Per Unit

1 Piece (MOQ)

Air Compressor Parts

15,000 - 150,000 Per Piece

10 pieces (MOQ)

Best Deals from Pollution Control Machines

Industrial Waste Shredder Machine

2,350,000 Per Piece

1 Piece (MOQ)

Shredding is a critical process in the management of industrial waste, which encompasses a wide range of materials generated by manufacturing, construction, chemical production, and other industrial activities. The diverse nature of industrial waste—ranging from metal scraps and plastics to chemicals and packaging materials—requires efficient and effective processing methods to ensure safe disposal and promote recycling and resource recovery.Key Roles of Shredding in Industrial Waste Management: Volume Reduction: Shredding reduces the volume of industrial waste, making it more manageable for storage, transportation, and disposal. This is especially important for bulky or dense materials, as it helps in optimizing space and lowering transportation costs, leading to more efficient waste management. Facilitation of Recycling and Resource Recovery: Shredding breaks down industrial waste into smaller, more uniform pieces, facilitating the separation and recovery of valuable materials such as metals, plastics, and rubber. These recovered materials can then be recycled and reintroduced into the production process, contributing to resource conservation and reducing the need for virgin materials. Preparation for Further Treatment: Shredded industrial waste is often easier to process in subsequent treatment stages, such as incineration, chemical treatment, or thermal decomposition. The increased surface area of the shredded material enhances the efficiency of these processes, ensuring more complete treatment and safer disposal. Improvement in Waste Handling and Safety: Shredding enhances the safety of handling industrial waste by reducing the size of sharp, hazardous, or awkwardly shaped materials. This minimizes the risk of injury to workers and reduces the likelihood of accidents during transportation and processing. Support for Energy Recovery: Shredded industrial waste can be used as a feedstock for waste-to-energy facilities, where it is incinerated to produce electricity or heat. The smaller, uniform particles produced by shredding improve combustion efficiency, resulting in higher energy yields and reduced emissions. Compliance with Regulatory Requirements: Shredding is often a necessary step to comply with environmental regulations governing industrial waste disposal. By breaking down waste into unrecognizable forms, shredding helps ensure that sensitive or hazardous materials are managed in accordance with legal standards, preventing environmental contamination and public health risks. Enhanced Landfill Management: When industrial waste is destined for landfill disposal, shredding ensures better compaction and stabilization of the waste. This extends the lifespan of landfills and reduces the environmental impact by minimizing voids and uneven settling, which can lead to operational challenges and increased greenhouse gas emissions. Reduction of Environmental Impact: Shredding industrial waste can significantly reduce its environmental footprint by enabling more efficient recycling, safe disposal, and energy recovery. This helps minimize the negative impacts of industrial activities on the environment and supports the transition towards more sustainable industrial practices. In summary, shredding plays a vital role in industrial waste management by reducing waste volume, facilitating recycling and resource recovery, improving safety, and supporting compliance with regulatory requirements. It enhances the overall efficiency and sustainability of managing industrial waste, turning potential pollutants into valuable resources.

Forward Curved Blower, Didw Fans

Get Price Quote

Ptfe Membrane Laminated Filter Bags

Get Price Quote

We are offering ptfe membrane laminated filter bags. we especially provide expanded ptfe membrane finishes for every type of dust collector filter bag application. Expanded ptfe membrane traps the particulate on surface and allows more air to pass through filter media. Bag house engineers are capable of reducing capital and operational cost as well as the ability to design bag house for higher air flow by using the eptfe membrane coated filter bags. The eptfe membrane is in most cases the best economic choice for filter media. Use of epfe membrane coated filter bags also provide a degree of protection from unpredictable and unknown changes which sometime occur during bag house operations. features: • material: ptfe membrane laminated on superior quality reliable fabric materials such as polypropylene, non-woven, pet and pe non- woven. • breathable filtration material • due to homogeneous pore size distribution is high. • it has collection efficiency and air permeability • it is water- and wind-resistant • it is usefully applied in chemistry and food stuff processing, electronics, mechanics. applications: • cement industry • coke industry • bitumen industry • steel industry • metallurgy industry • nonferrous metal industry • firepower electricity generation industry • fire proof materials and other coal powered fields for dust removal technical parameters: • fiber composition : ptfe membrane laminated on filter media • weight : 800g/m² (6.9 oz/yd²) • thickness : 1.2 mm • continuous operating temperature: 500°f ( ≤ 260 ℃ ) • maximum surge temperature : 538°f ( 280 ℃ ) • acid resistance : excellent • alkali resistance : excellent • tensile strength(n/5×20cm) : warp > 800, weft > 800 • tensile elongation(%) : warp

Centrifugal Blowers

13,800 - 158,500 Per piece

1 Piece(s) (MOQ)

We provide high quality Centrifugal Air Blowers for various applications such as dust collection, material conveying, fume extraction, drying, Ventilation purpose, cooling etc. We have carved a niche as the booming Centrifugal Blowers Manufacturer in India. Our wide array of Low Pressure Centrifugal Blower is available with Backward curve, Forward curve and radial fan blower. High efficiency fans that are used in our Low Pressure Centrifugal Blower assure low Power consumption. As per the demand of the client, various ranges of pressure and volume ratio are available.

bio waste composting machine

400,000 Per Piece

1 Piece (MOQ)

Non Woven Filter Bag

Get Price Quote

Features Abrasion resistance, high tensile strength Low resistance to filtration Single fiber, high porosity, gas filtration resistance Can be used in a variety of complex situation and harsh environmental conditions

Snap Ring Filter Bags

Get Price Quote

We are a renowned Manufacturer, Supplier and Exporter of Snap Ring Filter Bags situated in Delhi. We have in store some of the best Snap Ring Filter Bags prepared using a fine quality cloth that results in a durable Snap Ring Filter Bag ideal for an excellent filter quality. We cater to provide consumers customized filter bags in various sizes and shape to meet their varying demands. Advantages : Fine quality filters Highly durable Available in customized sizes and shape Available in normal rates

MLP Waste Grinder Machine

280,000 - 2,300,000 Per Piece

1 Piece (MOQ)

The MLP Waste Grinder Machine is a highly efficient and powerful solution designed for grinding various types of waste materials. This machine is available in a range of power options, typically from 15 HP to 25 HP, allowing it to meet different operational requirements effectively. The production capacity of the MLP Waste Grinder Machine is substantial, capable of processing 60 to 100 kg of waste per hour. This impressive capacity ensures that large volumes of waste can be handled efficiently, making it an ideal choice for waste management and recycling operations. Built with robust construction and advanced technology, the MLP Waste Grinder Machine offers reliable and consistent performance. It is designed to handle the rigorous demands of waste processing, ensuring thorough and efficient grinding of materials. This machine is essential for industries and facilities focused on waste reduction and recycling, providing a sustainable solution to manage and repurpose waste effectively. With its high-performance capabilities and durable design, the MLP Waste Grinder Machine is a valuable asset in promoting environmental sustainability and improving waste management practices.

PTFE Needle Felt Filter Bag

Get Price Quote

20 Bag (MOQ)

Wedge Wire Trommel Screen

3,300 - 9,000 Per Piece

Champion wedge wire trommel screens are highly efficient cylindrical rotating wedge wire screens used to separate solids from liquids or solids from solids. With trommel screens, the flow of materials is fed into the inside of the drum and the screen and centrifugal rotating action will force any particles smaller than the slot size through the screen and any particles larger than the slot size off the end of the screen. The wedge shape of the profile wires helps to minimise pegging and blinding. Champion can supply complete trommel units, including a motor and base frame, or a replacement screen for your existing unit. our wedge wire trommel screens are ideal for use in a variety of applications.

Bag Filter

45,000 Per Pieces

1 Pieces (MOQ)

Automatic Dust Collector

150,000 Per Piece

1 Piece (MOQ)

UD002 Dust Collector

Get Price Quote

1 Piece (MOQ)

air duct cleaning equipment

32,000 Per Piece

Dry Scrubber

Get Price Quote

1 Piece (MOQ)

Pocket Bag Air Filter

4,500 Per Piece

1 Piece (MOQ)

Pocket Bag Filters are made in both Ultra-fiberglass fiber or Synthetic media. The media is bonded to a thin non-woven synthetic backing and sewn with multiple rows of expanded stitching. These medium to high efficiency filters can be used in a variety of commercial and industrial applications as well as specialty applications such as oil mist collection, fume collection and collection of heavy concentrated file airborne contaminants. Pocket Bags are made in Ultra-fiberglass or Synthetic Media Open throat design for optimum air flow Available in MERV 11, 12, 13, 14, 15 and 16 Low initial pressure drop and superior dust holding capacity Galvanized steel header and J-channels for filter strength

Single Inlet Blowers

18,000 - 21,000 Per Piece

1 Piece (MOQ)

Pulse Jet Dust Collector

210,000 - 1,000,000 Per Piece

1 Piece (MOQ)