Vehicle Control Unit

Vehicle Control Unit (VCU/Control and Communication Unit) is based on the open control architecture and compliant to IEC-61375 "Train Communication Network" Protocol. It is suitable for WAP5/WAG9/WAP7 classes and its variants of 3-Phase Drive Electric Locomotives, fitted with either GTO or IGBT based Propulsion and Auxiliary Converters. Complete hardware and software (operating system, firmware and locomotive application software) is a single entity ready to be fitted in the locomotive. It can replace the MICAS-S2 VCUs. Designed based on the state of art technology, it eliminates the use of ASICs and addresses the obsolescence issue completely.

...more

Speedometer

The speed cum energy monitoring system is suitable for conventional AC tap changer as well as for three phase locomotives. The speed cum energy monitoring system has four essential functional components, viz. (i) Pulse generator, (ii) Signal conditioning Unit, (iii) Master unit and (iv) Slave unit.The system consists of Pulse generator (Tachometer), Signal conditioning unit (SCU), Recorder and Indicator unit (Master) and only Indicator unit (Slave).

...more

Speed Sensor

Rotational Speed Sensor for Traction Motors of 6000 HP Three Phase Drive Locomotives of Indian Railways was developed and supplied as a replacement to the existing passive Wiegand Type Sensor, which continues to have reliability problems. This is an active sensor with strong pulses having two output channels each with direction encoded signal making it 100% compatible to the Wiegand fed locomotive Electronics needing no modifications while retrofitting. The mechanical size and interface is identical to the existing Wiegand sensor and is powered directly by locomotive battery at 110V DC and can handle a variation of 77V to 138V. The sensor complies with IEC-60571 and IEC-61373 test standards.

...more

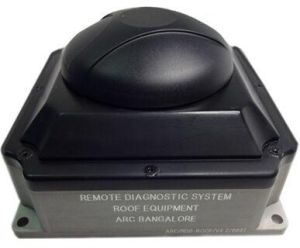

REMOTE DIAGNOSTIC SYSTEM

The remote diagnostic equipment collects the status of the locomotive, faults developed in a running locomotive and transmits to the base station server on real time on a wireless network. The equipment continuously polls the internal status of the locomotive and upon generation of any faults or system generated alerts, the same is captured and sent to a base server. The equipment is MVB based which gets connected to the WAP5/WAP7/WAG9 class of locomotives running in Indian Railways. The function of the equipment can be extended to cater to any type of rolling stock. There is an associated roof mounted unit which houses multiple modems and GPS receiver. Many process variables of the locomotive can be captured through MVB and transmitted to base station.

...more

Pressure Sensor

The Pressure sensor is made of piezo-resistive pressure sensor packaged in surface mount configuration and attached to a ceramic substrate, capable of an operating temperature(fluid temperature) of -40°C to +125°C. The sensing element associated with the amplifier and current converter,housed in a printed circuit board, will be embedded in a stainless steel housing. Packaged pressure sensor will work as a two wire sensor providing 4-20mA output corresponding to 0-4 bar pressure. The differential amplifier will be housed in an aluminium enclosure. The differential amplifier has two input channels and each of these input channel can accept a 4-20mA signal coming from the pressure sensor. The output of the amplifier is the difference of the two input pressures(differential) and is provided as 4-20mA signal. Both input and output signals are connected to the amplifier through 5 pin circular connectors of type KPSE06E14-5S and corresponding mating receptacle in the amplifier housing.

...more

Master Controller

The Master Controller developed by us will be suitable for WAP5, WAP7 & WAG9 classes of locomotives and its variants. It works using a different principle as compared to the master controllers currently being used in these classes of locomotives. The master controller has essentially three functional components, viz. (i) Angle Transmitter, (ii) CAM operated switches to sense TE (or BE), ZERO position, 1/3 position, 2/3 position & (iii) Forward/Reverse selector switch, which also has CAM operated switches and mechanically interlocked with the throttle handle.The heart of the master controller is the angle transmitter, which is expected to provide a current output (4-20mA) proportional to the angle position of the throttle handle. We have developed a angle encoder using Contact less rotary position sensor over 360°. It has huge advantage compared to the currently being used.

...more

LOCOMOTIVE DIAGNOSTIC SYSTEM

Locomotive Diagnostic Tool (Model LDS-04) was developed for trouble shooting and online diagnosis of the 6000 HP modern three phase locomotive fleet of Indian Railways equipped with MICAS-S2 control system of Bombardier Transportation. The equipment is built around a Pentium class processor and has a communication gateway enabling direct connection to the locomotive control system through the Multifunctional Vehicle Bus (MVB). The diagnostic tool becomes a network node on the MVB and all the vehicle processors can be accessed. The entire suite of MicTools (proprietary traction control software tools of Bombardier Transportation) can be run on this equipment to carryout many functions like control software download, fault log upload cum offline analysis, visualization and temporary forcing of process variables in real-time etc. The equipment is very compact, chassis cooled with dual input supply option of 110V DC and 230V AC 50Hz. USB interface and dual boot feature (DOS & Windows) are its unique features.

...more

FUNCTIONALLY EQUIVALENT PCBs

The present running 3-phase Electrical Locomotives using the design of MICAS S2 class of Electronic PCB’s are of late 1980’s vintage. Many components have already been declared obsolete by the OEM’s years ago. Due to this, the genuisness of many parts which are currently being purchased is not very certain. The failures are likely to increase in future and maintenance could be a serious problem.To overcome such difficulties we have undertaken re-design of MICAS S2 electronic PCB’s retaining the same functionality and straight-away interchangeable. In this connection we have already developed 10 types of PCB’s namely: 1. UF B701 A01 Bus Coupler Board 2. UF B660 A01 Bus Coupler Board 3. AR B705 B01 Signal Routing Board 4. UA B630 A91 Signal Conditioning Board 5. UA B630 A93 Signal Conditioning Board 6. UA B630 A36 Signal Conditioning Board 7. AF B635 B08 Fibre Optic Interface Board 8. UR B512 D15 Digital I/O Board 9. KU B921 A01 Power Supply Board 10. UA B514 B33 Analog I/O Board

...more

Fire Detection Unit

The Fire Detection Unit developed by us will be suitable for WAP5, WAP7 & WAG9 classes of locomotives and its variants. It is fitted inside the machine room of Locomotive to detect smouldering fires as well as flaming fires that produce smoke. Fire Detection Unit gives an alarm warning signal to Cab-Pilot along with the LED indication.Fire Detection Unit contains two smoke detectors, suction unit with air-flow monitoring, visual indication of Operation, fault/malfunction, Alarm, connection for pipe with 25mm outside diameter, potential free relays. The unit works at nominal voltage of 24V DC.

...more

DRIVER DISPLAY UNIT

The Driver Display provides 800x600 VGA graphic and works as a man machine interface. Made as a panel mount equipment, it uses 10.4” LCD TFT display. Various fault messages and system generated prompts are displayed on screen. Driver is able to navigate through the menu using dedicated function keys. USB drive facilitates data exchange. The unique feature of this display is that it retains the exisiting 4x40 character display format of the existing WAG9/ WAP7/ WAP5 class of three phase locomotives of Indian Railways as well as provides a graphic mimic window in which various process variables can be seen by selecting pre-defined screens using function keys. The display has both MVB and RS422 interface.

...more

doppler radar

Doppler Radar based Adhesion Control System is developed for improving the realizable adhesion in WAG9 & WAG9H class locomotives during wheel slip conditions which occurs due to bad weather and poor track conditions. Using a Doppler Radar, the ground speed is detected, which is compared with each axle speed. The slipping bogie is identified precisely and instantaneous tractive effort correction is applied to bring the condition to non-slipping state. After slip is controlled, the tractive effort is restored back to the original value or to a safe level where re-adhesion is achieved.

...more

Distributed Power Wireless Control System

Distributed Power Wireless Control System was developed for WAG9 & WAG9H class of locomotives to provide Distributed Power Operation for achieving heavy haul. Using DPWCS, Distributed Power (DP) operation is possible through wireless. In DP operation, two or more locomotives are attached in one train but dispersed at different locations. The operation command of the train is achieved from the lead loco known as the Master using a single set of crew. Other locomotives are Slaves which receives command from the Master and do not normally have crew. The Slave locomotives which are distributed in a train, obeys the command from the master locomotive through radio signals. DP operation enables heavy haul and other benefits like increased throughput.

...more

Display Unit

The Driver Display provides 800x600 VGA graphic and works as a man machine interface. Made as a panel mount equipment, it uses 10.4” LCD TFT display. Various fault messages and system generated prompts are displayed on screen. Driver is able to navigate through the menu using dedicated function keys. USB drive facilitates data exchange. The unique feature of this display is that it retains the exisiting 4x40 character display format of the existing WAG9 WAP7 WAP5 class of three phase locomotives of Indian Railways as well as provides a graphic mimic window in which various process variables can be seen by selecting pre-defined screens using function keys. The display has both MVB and RS422 interface.

...more

Angle Transmitter

The Master Controller developed by us will be suitable for WAP5, WAP7 & WAG9 classes of locomotives and its variants. It works using a different principle as compared to the master controllers currently being used in these classes of locomotives. The master controller has essentially three functional components, viz. (i) Angle Transmitter, (ii) CAM operated switches to sense TE (or BE), ZERO position, 13 position, 23 position & (iii) ForwardReverse selector switch, which also has CAM operated switches and mechanically interlocked with the throttle handle. The heart of the master controller is the angle transmitter, which is expected to provide a current output (4-20mA) proportional to the angle position of the throttle handle. We have developed a angle encoder using Contact less rotary position sensor over 360°. It has huge advantage compared to the currently being used.

...moreBe first to Rate

Rate ThisOpening Hours