Powder Spray Gun

Powder spray guns can usually be adjusted to provide a powder discharge to suit particular circumstances. At the lower end of the discharge rate, flow of powder can be from 100-200gmin (approximately 6-12kghr), and at the higher end , at a rate of 500-600gmin (approximately 30-36kghr). At 14kghr, assuming 60% deposition, efficiency of the powder ejected from the gun, at a film build-up of 50µ, 1.74m2 per minute of surface can be coated.

...more

powder curing ovens

The powder supplier refers to the article temperature itself and not to the air or panel temperature of an emitter. The powder coated pieces are then carried into this space where they absorb heat, reach the surrounding temperature and are held at this temperature for the specified time.

...more

Electrostatic Sprayer

The powder is usually contained in a hopper adjacent to the application booth. It then passes through the electrostatic spray gun, which charges the particles on emission, causing them to deposit on the earthed workpiece. Subsequent fusion and curing takes place in an oven. Powder not deposited on the workpiece is collected and re-used.

...more

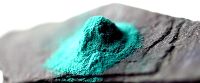

Colour Powder Coatings

Powder Coatings we are proud of our commitment to sustainable and environmentally friendly products and technology. It’s a serious commitment, and our objective is to remain in the top three in the Dow Jones Sustainability Index. our powder coatings. And we are the world leader in TGIC-free technology. (Ttriglycidyl Isocyanurate is a cross linker used as a curing agent in powder coatings since the 1970s).

...more

Coating Powders

We are a respected name from Mumbai(India) and involved in catering to the varied demands of the customers. Our range is manufactured strictly as per the globally accepted norms, thus, you can rely on us completely.

...more

Coating Materials

Be first to Rate

Rate This