Vertical Column Type Honing Machine

Avail high performance vertical column type honing machine from us. We make available precision engineered vertical column type honing machine in market. Our vertical column type honing machine is appreciated for its accurate dimensions and reliable performance. Furthermore, vertical column type honing machine is available with us at reasonable prices. features rugged constructionrunning on linear guidesautomatic or manualplc controlledhigh surface finishtrue cylindrical form with respect to roundness and straightnessrapid and economical stock removallow power consumptionprecise dimensional controllow floor spacehigh cutting speed

...more

Superfinishing Attachments

Super Finishing Machine, that we offer, is a twin headed super finishing machine that is specially designed for perfect finishing of cylindrical components. This Component Finishing Machine improves the quality and life of the products. We make available bi-fully automatic Super Finishing Machine that functions with separate roughing and finishing cycle. Salient Features High precision live Spindle and hydraulic tail stock for holding the components between centreInfinitely variable Spindle speed through VF Drive with separate preset speeds for roughing and finishing cycleDouble vibratory heads mounted 90 degree apart for roughing and finishing operationRz value of up to 0.2 micron ( Ra value of 0.02 micron ) possibleHuman intervention is required only to load unload the components to the machine (Automatic loading unloading is optional)Hi-tech hydraulic power unit and electrical control panel to run the machine in fully automatic cycleSingle cycle start button to complete the entire cycle Advantages Improved surface finish up to Rz value of 2.0 micronsGreater efficiency of productsConsistent Rz value en all componentsImproves productivityLess human intervention Applications Gear pump shaftsValves and valve spoolsBearing rollersPlug gaugesPomp pistonsPiston rods etcBottom of Form

...more

Super Finishing Machine

super finishing machine, that we offer, is a twin headed super finishing machine that is specially designed for perfect finishing of cylindrical components. This super finishing machine improves the quality and life of the products. We make available bi-fully automatic super finishing machine that functions with separate roughing and finishing cycle. salient features high precision live spindle and hydraulic tail stock for holding the components between centreinfinkely variable spindle speed through vf drive with separate preset speeds for roughing and finishing cycle.double vibratory heads mounted 90 degree apart for roughing and finishing operationr2 volue of up to 0.2 micron ( pa value of 0.02 micron ) possiblehurnan intervention is required only to load unload the components to the machine (automatic loading unloading is optional).hi-tech hydraulic power unit and electrical condol panel to run the machine in fully automatic cycle.single cyole gaa hot, to complete the entire cycle. advantages improved surface finish up to rz value of 2.0 micronsgreater efficiency of productsconsistent rz value en all componentsimproves productivityless human intervention applications gear pump shaftsvalves and valve spoolsbearing rollersplug gaugespomp pishonspiston rods etc.

...more

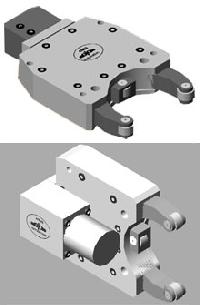

Steady rests

Arms grinding steady rest is an apt design for holding long slender cylindrical jobs. This steady can be specially used in CNC as well as mannual grinding machine by it’s compatibility of programming & interfacing with the cnc system. Arms steady rests are designed to get optimum result in accurate grinding of long slender jobs .Arms steady rests are designed for getting high productivity by eliminating rejection and the setting time of manual steady rests.Arms steady rests are designed according to the customers’ requirement of job sizes. These are hydraulically operated steady rests. Side mounted and rear mounted cylinder designs are also available according to the bed design of machine.Arms steady rests are at par to the international standard by manufacturing & design yet very competitive in price ! These steady rests are dimensionally interchangeable with any other similar models available in the market.

...more

servo rotary table

Material Handling Robot Arm

We hold expertise in manufacturing and supplying high performance robo arms for material handling. We make available robo arms for material handling in compliance with the customers’ requirements and specifications. Robo arms for material handling, offered by us, are suitable to perform in any bad working environment and condition, where human presence is not possible. attributes robust constructionprecision engineeredhigh performancemade with premium raw materials

...more

Linear Swing Type Honing Machine

We are the one stop shop in market for availing feature packed linear swing type honing machine. Linear swing type honing machine, that we offer, is made with the best quality components and is in compliance with the international quality standards. Our linear swing type honing machine has varied industrial applications. features rugged constructionextended tool lifetrue cylindrical form with respect to roundness and straightnessinline honing head movement with respect to bore axis same as column typelow floor spaceautomatic or manualuniform cutting forcenew mechanismhigh surface finishlow power consumptionprecise dimensional controlhigh cutting speedrapid and economical stock removal

...more

Hydraulic Turret

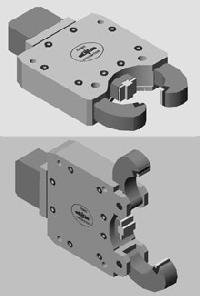

Hydraulic Self Centering Steady Rest

Hydraulic Self Centering Steady Rest, offered by us, is compact and ideal for holding of round jobs. Our Hydraulic Self Centering Steady Rest saves time and eliminates rejection of jobs. Hydraulic Self Centering Steady Rest, that we offer can be programmed through the CNC system. Our Hydraulic Self Centering Steady Rest is known for giving good centering accuracy & the repeatability. We make available various models of Hydraulic Self Centering Steady Rest, such as side mounted cylinders, rear mounted cylinders, pneumatic ,servo controlled etc. Our Hydraulic Self Centering Steady Rest has special rollers that give good surface finish. Lubrication system and fully heat treated parts give better life for our Steady Rest. Salient Features The steady rest can be used for any CNC lathes with a suitable bracketNo Setting time for the change of job diameterThe steady can also be used as a travelling steady, hence no need of a follower restRepeatability is within 5 microns Applications Machining of Long Slender ShaftsFor end operationsAutomatic Holding of Jobs In CNC Turning MachinesCrank Shaft MachiningFor Grinding Applications Working principle The steady rest consists of 3 arms assembled in a steel body with rollers at the arms for holding the work piece. The centre one brings the other two arms in a circular movement to hold at the center of the work piece .This helps to get the repeatability and consistency in getting the centering accuracy The centre arm is operated by a hydraulic cylinder. The job holding rollers are lubricated through centralized lubricating system. Types of Steady Rests Hydraulic Self Centering Steady rest with rear mounted cylinderHydraulic Self Centering Steady rest with side mounted cylinderPneumatic Self Centering Steady restSelf Centering Steady rest with servo controlHydraulic Self Centering Steady rest for grindingHydraulic Self Centering steady rest for crank shaft grindingHydraulic Self Centering steady rest for crank shaft turningHydraulic Self Centering steady rest for cam shaftsHydraulic Self Centering steady rest for special purposeHydro pneumatic self centering steady rests

...more

hydraulic honing machines

H Frame Hydraulic Press

h frame hydraulic press offered by us is in accordance with european norms like linear encoder, plc photo safety guards, etc. H frame hydraulic press, offered by us, draws tough and precision components perfectly. H frame hydraulic press has intricate drawing applications like manufacturing of automotive parts, aeronautical components, surgical equipment, etc. All the parts of our h frame hydraulic press are lubricated with centralized lubrication unit. Single action drawing presses with bottom cushioning and double action drawing press with blank holders are available in our h frame hydraulic press. The adp series presses are available in both, h type and 4 pillar type. applications extrusion presseshot forging pressesmoulding pressesdeep drawing pressesand for various custom built applications features heavy duty rugged constructionhigh precision pressing due to ram movement on precision guideframe selected through computer aided design and finite element analysislow operating costs compared to other modelsfast automatic cycles controlled by plc technical specificationsmodelcapacity (tons)table size l.r.x.f.bdaylight (mm) stroke (mm)fast approach speed (mmsec)slow pressing speed (mmsec)return speed (mmsec)bottom cushioning capacity (tons)cushion stroke (mm)motor hpadp-3030500x4004003002001015121501215010adp-6060600x5005004002001015121502517015adp-8080900x7005004002501015122003220015adp-1001001000x7506505003001015122504020020adp-1501501000x8508506503001015122506025025adp-2002001200x10009507003001015122508025030adp-2502501400x1100100075030010151225010028040adp-3003001500x1200110080030010151225012530050adp-4004001800x1300120090030010151225015035060adp-5005002200x15001350100030010151225020035075adp-6006002500x150015001100300101512250250400100adp-8008002800x200016001200300101512250300450125adp-100010003000x220016001200300101512250400450150

...more

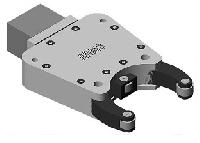

Grinding Steady Rest

We are the one stop destination in market for availing top grade Grinding Steady Rest. Our Grinding Steady Rest is ideal for holding long slender cylindrical jobs. Our Grinding Steady Rest is suitable for both, CNC and manual grinding machine. Grinding Steady Rest, that we offer, is hydraulically, pneumatically or servo operated. This Grinding Steady Rest is available in side mounted and rear mounted cylinder designs. We make available Grinding Steady Rest that is dimensionally interchangeable with other similar models. Applications Machining of Long Slender ShaftsAutomatic Holding of Jobs In CNC grinding MachinesCrank Shaft ,cam shaft grindingFor any type Grinding Applications Salient Features The Steady Rest Can Be Used For Any Machine Including CNC grinders With a Suitable BracketThe Steady Can Also Be Used As A Traveling Steady Hence No Need Of A Follower RestHigh centering accuracy because real cam technology usedPass through grinding possibleContinues support while part being groundRepeatability Is Within 2 Microns Working principle The steady rest consists of 3 arms assembled in a steel body with carbide pads at the arms for holding the work piece. The centre one brings the other two arms in a circular movement to hold the center of the work piece .This helps to get the repeatability, consistency and centering accuracy. The centre arm is operated by a hydraulic,pneumatic cylinder or servo motor. Types of Steady Rests Hydraulic Self Centering Steady rest with rear mounted cylinderPneumatic Self Centering Steady restSelf Centering Steady rest with servo controlHydraulic Self Centering steady rest for crank shaft grindingHydraulic Self Centering steady rest for cam shaftsHydraulic Self Centering steady rest for vertical loading Standard Range of Grinding Steady Rest are the FollowingModel No.Diameter RangeApplicationsAGU 110 to 30mmFor Normal Grinding Application AGU 220 to 60mmAGUV 110 to 30mmFor Normal Grinding Application with Vertical LoadingAGUV 220 to 60mmACU 1ACUV140 to 70mmFor Crank Shaft Grinding Application with or with Out Vertical LoadingACU 2ACUV245 to 110mm ACU 3ACUV370 to 150mmACU 4ACUV450 to 200mm Note : However, the steady rest can be designed as per customer’s requirement.

...more

Cnc Lathe Steady Rest

Designed to perfection, CNC Lathe Steady Rest, offered by us, is sure to give excellent result in automatic holding of cylindrical jobs. This CNC Lathe Steady Rest is known for offering the best repeatability in microns and centering accuracy. Due to interchangeability in mounting dimensions, our CNC Lathe Steady Rest can be replaced with any other similar model. Hydraulically operated, this CNC Lathe Steady Rest can be interfaced with the CNC system. Our CNC Lathe Steady Rest runs the job in high rpm and gives premium surface finish. Applications Machining of Long Slender ShaftsEnd operation of shaftsAutomatic Holding of Jobs In CNC Turning MachinesCrank Shaft Machining Salient Features The Steady Rest Can Be Used For Any Machine Including CNC Lathes With a Suitable BracketThe Steady Can Also Be Used As A Travelling Steady Hence No Need Of A Follower RestRepeatability Is Within 5 Microns Working principle The steady rest consists of 3 arms assembled in a steel body with rollers at the arms for holding the work piece. The centre one brings the other two arms in a circular movement to hold the center of the work piece .This helps to get the repeatability and consistency in getting the centering accuracy The centre arm is operated by a hydraulic cylinder. The job holding rollers are lubricated through centralized lubricating system. Types of Steady Rests Hydraulic Self Centering Steady rest with rear mounted cylinderHydraulic Self Centering Steady rest with side mounted cylinderPneumatic Self Centering Steady restSelf Centering Steady rest with servo controlHydraulic Self Centering Steady rest for grindingHydraulic Self Centering steady rest for crank shaft grindingHydraulic Self Centering steady rest for crank shaft turningHydraulic Self Centering steady rest for cam shaftsHydraulic Self Centering steady rest for special purposeHydro pneumatic steady rests

...more

Centering Machine

Centering and Facing Machines are most suitable for centering, chamfering and external turning of the two ends simultaneously of the bar stock, such as camshafts, crankshafts, motor-shafts, universal joint, spinders etc. ensuring perfect alignment of centers, accurate length and true end. These are available in four length capacities. The combined centering and facing operation saves machine time, handling time and floor space. The machine has two Hydraulic operated self centering work holding vices with push button control. The cutting cycle is operated with push button on a fast approach slow feed and rapid return basis.

...more

Honing Machine

material handling robo arms

steady rest

Hydraulic Press

hydraulic honning machine

Special Purpose Machines

Chamfering Machine

Hydraulic Power Pack

Hydraulic Cylinder

overhead gantry crane

Be first to Rate

Rate ThisOpening Hours