Venturi Scrubber

A Venturi Scrubber consists of three sections: a converging section, a throat section, and a diverging section. The inlet gas stream enters the converging section and, as the area decreases, gas velocity increases (in accordance with the Bernoulli equation). Liquid is introduced either at the throat or at the entrance to the converging section. The inlet gas, forced to move at extremely high velocities in the small throat section, shears the liquid from its walls, producing an enormous number of very tiny droplets. Particle and gas removal occur in the throat section as the inlet gas stream mixes with the fog of tiny liquid droplets. The inlet stream then exits through the diverging section, where it is forced to slow down. The dirty liquid carrying the pollutant particulate matter is then removed in a separator and discharged into a recycle tank some of the liquid is continuously purged to limit the solids concentration and allow recirculation back to the Venturi section. Venturis can be used to collect both particulate and gaseous pollutants, but they are more effective in removing particles than gaseous pollutants.

...more

Static Pass Box

The application of pass box is for movement of small handy products. Generally pass boxes are mounted at 3’ – 0” level from the floor for convenience of operators. Pass boxes are classified into two types. STATIC PASS BOX Pass boxes used to move material from a classified area to another classified area are called static pass box. Modular Clean room with HVAC systems CONSTRUCTION All pass boxes are tailor made to suit customer requirement. Combination of GI powder coated with SS and all SS construction is standard practice of manufacturing. Door interlocking, Buzzer, white light, UV light, hour running meter are standard accessories in pass box design.

...more

Spray Painting Booths

BATS manufacture spray painting booth with the customized sizes. The exhaust system remove the paint fume laden air inside the painting zone. BATS spray painting booths are available in two types. Painting Booth 1. Wet type This type of spray painting booth will have water screen to scrub the exhaust fume laden air before dispersing to the atmosphere. This painting booth will have internal water sump, water screen plate, water re circulating system, rear side draft section with exhaust blowers and spray painting zone. If the paint booth has to be closed one, we provide make up fresh air system as optional. 2. Dry type This type of spray painting booth will have filter media (paper fabric) to eliminate the paint fume from the exhaust air. This paint booth will have filter section in the rear draft plenum.

...more

scrubber unit

Several industries generate toxic fumes, vapours along with dust during their manufacturing process. These processes need an exhaust system from three aspect.

Feature : To ensure the operators health and safety by removing the hazardous fumes from the working area To avoid pollution problems Sturdy construction To increase the product quality removing fumes from the process.

...more

Plate Scrubber Unit

An impingement-plate scrubber is a vertical chamber with plates mounted horizontally inside a hollow shell. Impingement-plate scrubbers operate as countercurrent particulate matter (PM) collection devices. The scrubbing liquid flows down the tower while the gas stream flows upward. Contact between the liquid and the particle-laden gas occur on the plates. The plates are equipped with openings that allow the gas to pass through. Some plates are perforated or slotted. The simplest impingement-plate scrubber is the sieve plate, which has round perforations. In this type of scrubber, the scrubbing liquid flows over the plates and the gas flows up through the holes. The gas velocity prevents the liquid from flowing down through the perforations. Gas-liquid-particle contact is achieved within the froth generated by the gas passing through the liquid layer. Complex plates, such as baffle plates, introduce an additional means of collecting PM. The baffles placed above the plate perforations force the gas to turn before escaping the layer of liquid. While the gas turns to avoid the obstacles, most PM cannot and is collected by impaction on the baffles.

...more

Packed Bed Scrubber

BATS packed bed scrubbers are versatile, reliable systems that serve the widest variety of processes. BATS packed scrubbers are highly recommended for the efficient removal of inorganic gases, odors and fumes, and are particularly appropriate where gas streams have extreme pH. They are well suited for use as primary or secondary systems in conjunction with thermal oxidizers, and are also used in a series where there are multiple-contaminant gas streams. There are four broad categories of information, which influence the design of these systems. Packed Bed Scrubber CMH Air flow through the scrubber, based on cubic meterhr. This is determined by the process to be handled by the scrubber, through information provided by customer and BATS analysis. Configuration Internal vs. external re-circulation system, fan location in relation to tower, duct sizes, inlet and outlet plus location of pump systems, tower access service ports, service platform requirement. Materials of Construction Determined by application; because most contaminants involve corrosive gases and fumes, material must be able to withstand continuous contact with high and low pH gases and scrubbing solutions. Standard construction materials include: polypropylene, fiberglass and PVC. Optional materials include high alloy metals such as stainless, also dual-laminate structures incorporating FRP over PVC, PP is available.

...more

Mechanical Ventilation Systems

Large industrial areas are not economical to provide temperature controlled air conditioning system. Alternatively to enhance the indoor operators comfort level a filtered fresh air ventilation system is most suitable with adequate number of air changes as per ventilation standards & WHO standards. Generally, mechanical ventilation system is required, Cyclone Separators To provide necessary comfort level conditions for maintaining the efficiency, health and safety of the workers To control hazardous concentrations of toxic materials in the indoor air To maintain cleanliness level of indoor air To maintain adequate oxygen supply in the work area To remove any undesirable odors from a given area. Ventilation Design Parameters are Manufacturing process Exhaust air system & local extraction Cleanliness requirements Ambient air conditions Heat emissions Contaminant emissions Regulations

...more

industrial air scrubber

Air conditioning is the mechanical replacement of heat with cooled air. The indoor air quality – related to industrial Air conditioning is major concern to meet process related, product related activities. Basic design is as per ACGIH standards & to meet good manufacturing practices. Air conditioning systems are required generally in industry

...more

Industrial Air conditioning control

Air conditioning is the mechanical replacement of heat with cooled air. The indoor air quality – related to industrial Air conditioning is major concern to meet process related, product related activities. Basic design is as per ACGIH standards & to meet good manufacturing practices. Air conditioning systems are required generally in industry Air Conditioning with RH Control To maintain indoor dry bulb temperature & percentage of relative humidity under controlled levels to meet critical process and product requirement. To create comfort zone by maintaining indoor air quality A deadly enemy of most electronic equipment and personal productivity is heat. Machinery used to produce critical equipment or to do some precision work requires constant cooling to function properly. In a commercial facility production area, personal comfort level is very much important by maintaining good indoor air quality to maintain health of personal in turn to increase the productivity. Air conditioning system Design Parameters are: Manufacturing process Required indoor conditions Outdoor ambient conditions Connected equipment load Heat emissions No. of people presence inside the environment Sunlight exposed surface area of enclosure Lighting load Cleanliness requirements Heat emissions Regulations

...more

industrial air conditioning

Air conditioning is the mechanical replacement of heat with cooled air. The indoor air quality – related to industrial Air conditioning is major concern to meet process related, product related activities. Basic design is as per ACGIH standards & to meet good manufacturing practices. Air conditioning systems are required generally in industry To maintain indoor dry bulb temperature & percentage of relative humidity under controlled levels to meet critical process and product requirement. To create comfort zone by maintaining indoor air quality A deadly enemy of most electronic equipment and personal productivity is heat. Machinery used to produce critical equipment or to do some precision work requires constant cooling to function properly. In a commercial facility / production area, personal comfort level is very much important by maintaining good indoor air quality to maintain health of personal in turn to increase the productivity. Air conditioning system Design Parameters are: Manufacturing process Required indoor conditions Outdoor ambient conditions Connected equipment load Heat emissions No. of people presence inside the environment Sunlight exposed surface area of enclosure Lighting load Cleanliness requirements Heat emissions Regulations The applications of these systems are as under: Pharmaceutical / Bulk Drug industries Photo / electronics industries Food Industries Biotechnology, bioscience laboratories Clean rooms (engineering / biotech / pharma products / Assembly of precision components)

...more

Vertical Laminar Air Flow Bench

LAMINAR AIR FLOW BENCH is classified based on the air flow pattern. If the Airflow pattern is horizontally across the work table is called horizontal laminar air flow and if the air flow is vertically downwards on the work table surface is called vertical laminar air flow. In both types principally the room air is taken through a pre filter which arrest larger size particle by which the life of HEPA filter increases. The pre filtered air is forced through HEPA filter, results a stream of unidirectional clean air flow within the work table surface of the work bench. A nominal filter face velocity of 80 to 100 fpm ensures sufficient number of air changes in order to maintain desired cleanliness level. The filtered air moves out from the front open space of cabinet. The LAF unit is constructed out of GI powder coated sheets & MS powder coated sections in combination with SS work table surface or alternatively all SS construction. The front shutter is of polycarbonate panel moves up and downwards with easy movement balanced by counter weight. Pre filter & HEPA filter is provided with protective grill to prevent accidental damages. The supply air blowers are centrifugal, direct drive type, self lubricated, extremely low noise level and free from vibrations. The unit is provided with white light, UV light, pressure gauge to monitor pressure across HEPA filter. The electrical switches to operate blower, lights are of superior quality and assures safety to operators. All units are factory tested before dispatch. The equipment designed for maximum chemical resistance, longer service life, durability and are clean room compatible. The sizes as per work table size. The available standards are as under 2 Ft. x 2 Ft. 3 Ft. x 2 Ft. 4 Ft. x 2 Ft. 6 Ft. x 2 Ft. 8 Ft. x 2 Ft.

...more

Fume Scrubbing Exhaust System

Several industries generate toxic fumes, vapours along with dust during their manufacturing process. These processes need an exhaust system from three aspect. To ensure the operators health and safety by removing the hazardous fumes from the working area To avoid pollution problems Sturdy construction To increase the product quality removing fumes from the process The unwanted fumes generated during the process will be exhausted through properly designed suction hood with required capture velocity. The exhaust air will be routed through a Packed bed scrubber / Plate scrubber / Venturi scrubber to eliminate hazardous fumes, odour & dust in the exhaust air & clean air will be exhausted to ambient. Fume scrubbing / Extraction system comprises of following LEVs / Suction hood Ducting Packed bed scrubber / Plate scrubber / Venturi scrubber Pump to handle scrubbing liquid Blowers Chimney BATS offer an excellent, custom built, efficient fume scrubber system to tackle fumes, vapours, dust generated in many process industries. The system will be designed such way that the hazardous fume will be exhausted from the point of generation itself by providing Local Exhaust Vents ( LEVs). The system design, material of construction, system capacity all are related to the type of industry, type of fumes, vapour & dust, location of generation. BATS offers fume scrubbing system compliance with standard pollution control norms. This system is made to order hence basic design data need to be furnished to design, install the scrubber systems. Features: Precision functioning Sturdy construction Works at toughest conditions Durable Low maintenance Creating Hygienic working atmosphere. High employees' acceptance. Increased productivity. Prevents corrosion of crane & roof structure. Increased safety. Fumes are condensed & recycled, optimizing material us

...more

Exhaust System

Several industries generate toxic fumes, vapours along with dust during their manufacturing process. These processes need an exhaust system from three aspect. Fume Scrubbing Unit To ensure the operators health and safety by removing the hazardous fumes from the working area To avoid pollution problems Sturdy construction To increase the product quality removing fumes from the process The unwanted fumes generated during the process will be exhausted through properly designed suction hood with required capture velocity. The exhaust air will be routed through a Packed bed scrubber Plate scrubber Venturi scrubber to eliminate hazardous fumes, odour & dust in the exhaust air & clean air will be exhausted to ambient. Features: Precision functioning Sturdy construction Works at toughest conditions Durable Low maintenance Creating Hygienic working atmosphere. High employees' acceptance. Increased productivity. Prevents corrosion of crane & roof structure. Increased safety. Fumes are condensed & recycled, optimizing material us

...more

Evaporative Cooling System

Evaporative cooling systems have added advantage in achieving higher comfort level in manufacturing & general engineering industries. Ventilation supply air systems draws the outside air & filter it to the required micron level & distribute air to occupied areas to meet comfort. In evaporative cooling system, the same fresh air system is equipped with a water circulated cooling pad & the filtered dry air at ambient temperature is allowed to pass through cooling pad, their by the dry bulb temperature of air it will brought down and cooled air will be distributed to the occupied areas. Which make more comfort if the occupied area. This is an adiabatic cooling process where large occupied areas to be brought under comfort level. Evaporative cooling system is working with the principle that when the air is passing through water circulated cooling pad, water will be evaporated by taking the energy (heat) from the fresh dry air in an adiabatic process, due to the difference between dry bulb temperature and wet bulb temperature. Energy loses due to change water from liquid to vapour results in reduction of dry bulb temperature of air. These systems are more suitable and efficient where ambient temperature is too high & low RH levels. In case if it use a chilled water spray in the cooling pad in place of normal water the room temperature will be still better & close to air conditioning comfort. This application has a main disadvantage is the relative humidity level will be high (over 70%) which place an important role & can affect the manufacturing process & products where the humidity levels are the criteria. Evaporative cooling system comprises of following Air inlet section Filters Water circulated cooling pad Re circulation water pump with internal water sump Blowers / Air Handing units Ducts Register/grills for distributing the air within the work space

...more

Dynamic Pass Box

Pass boxes are used to move material from unclassified area to classified area are called dynamic pass box. All dynamic pass boxes are fitted with HEPA filtered air circulation system. All dynamic pass boxes are design to class 100 cleanliness level. Dynamic pass boxes are large by height to accommodate HEPA filtered air circulation system. CONSTRUCTION All pass boxes are tailor made to suit customer requirement. Combination of GI powder coated with SS and all SS construction is standard practice of manufacturing. Door interlocking, Buzzer, white light, UV light, hour running meter are standard accessories in pass box design.

...more

Dust Proofing Pressurization Systems

Dust Proofing System is requirement of certain process / activities such as assembly of precision components, packing of precision products, painting process, electronic components assembly. Dust proofing environment requirement arises To keep the environment as dust free zone to suit to the process / activity To create comfort level and more Hygienic environment for the occupants in a specified area, if the outside area is having pollutant like dust or any hazardous chemica To meet dust proofing system, the process area is provided with filtered fresh air systems. The classification of filtration depending on the process/ equipment. To obtain dust proof zone the area need to be air tight to arrest leakage of supply air to establish positive pressure inside the area with respect to outside area or adjacent areas. The positive pressure inside will prevent dust / hazardous entry from outside. This helps the process in a dust free environment. We can add cooling system also in the air handling unit of the pressurization system based on the requirement of process. Air lock rooms for material entry & men entry are must for dust proof systems. The in dust generation & heat generated by process can be tackled by suitable extraction system & can not only be controlled by dust proof systems.

...more

pressurization systems

Dust Proofing System is requirement of certain process activities such as assembly of precision components, packing of precision products, painting process, electronic components assembly. Dust proofing environment requirement arises To keep the environment as dust free zone to suit to the process activity To create comfort level and more Hygienic environment for the occupants in a specified area, if the outside area is having pollutant like dust or any hazardous chemica DUST PROOFING To meet dust proofing system, the process area is provided with filtered fresh air systems. The classification of filtration depending on the process equipment. To obtain dust proof zone the area need to be air tight to arrest leakage of supply air to establish positive pressure inside the area with respect to outside area or adjacent areas. The positive pressure inside will prevent dust hazardous entry from outside. This helps the process in a dust free environment. We can add cooling system also in the air handling unit of the pressurization system based on the requirement of process. Air lock rooms for material entry & men entry are must for dust proof systems. The in dust generation & heat generated by process can be tackled by suitable extraction system & can not only be controlled by dust proof systems.

...more

Dust Extraction Collection System

Recovery of particulate matter from exhaust gas is vital for any industry from three aspect To ensure the operators health and safety by removing the hazardous fumes from the working area To avoid pollution problems Sturdy construction To increase the product quality removing fumes from the process Dust collection systems is used in many processes to either recover valuable granular solid or powder from process streams, or to remove granular solid pollutants from exhaust gases prior to venting to the atmosphere. Dust collection is an online process for collecting any process-generated dust from the source point on a continuous basis. Dust collectors may be of single unit construction, or a collection of devices used to separate particulate matter from the process air. They are often used as an air pollution control device to maintain or improve air quality. The dust generation in manufacturing process directly effects the operator’s health, can contaminate the product which is being manufacturing can make highly uncomfortable for the people in & around the dust generating areas. BATS wish to offer a solution by incorporating dust control & extraction system & ensure a safe & pure zone for the occupants. This process involves exhaust blowers, exhaust air duct work and dust collection hoods to pick up dust particles at the point of generation. In several cases, the dust collected by the system from the point of generation is routed through a filter unit which collects the dust & pure air will be exhausted to the ambient to meet pollution control. Dust collection / Extraction system comprises of following LEVs / Suction hood Ducting Volume control dampers / Shut off dampers at branch ducting Cyclone / Unit dust collector / Bag filter Centrifugal Blowers Chimney

...more

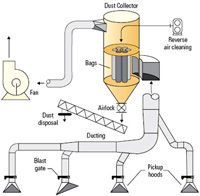

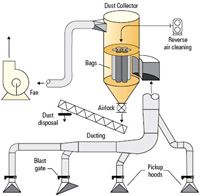

Dust Extraction System

Recovery of particulate matter from exhaust gas is vital for any industry from three aspect Dust Extraction Diagram To ensure the operators health and safety by removing the hazardous fumes from the working area To avoid pollution problems Sturdy construction To increase the product quality removing fumes from the process Dust collection systems is used in many processes to either recover valuable granular solid or powder from process streams, or to remove granular solid pollutants from exhaust gases prior to venting to the atmosphere. Dust collection is an online process for collecting any process-generated dust from the source point on a continuous basis. Dust collectors may be of single unit construction, or a collection of devices used to separate particulate matter from the process air. They are often used as an air pollution control device to maintain or improve air quality. The dust generation in manufacturing process directly effects the operator�s health, can contaminate the product which is being manufacturing can make highly uncomfortable for the people in & around the dust generating areas. BATS wish to offer a solution by incorporating dust control & extraction system & ensure a safe & pure zone for the occupants. This process involves exhaust blowers, exhaust air duct work and dust collection hoods to pick up dust particles at the point of generation. In several cases, the dust collected by the system from the point of generation is routed through a filter unit which collects the dust & pure air will be exhausted to the ambient to meet pollution control.

...more

Double Single Skin Air Handling Units

BATS offer Air Handling Unit in both options Single skin Construction and Double skin construction. Single skin constructed AHUs are to be used in Fresh air Ventilation System. Single skin constructed AHUs are built by using heavier gauge sheets (18 20 SWG Galvanized sheet). Air Handling Unit Double skin AHUs are constructed by using PUF insulated panels. The panel outer skin may be with 2022 SWG GI sheet and the panel inner skin may be with 24 SWG GI sheet. PUF slabs will be used as core insulation of AHU panels. The thickness of panel may be 25 40 50 mm. Thickness of panel will be decided with application and size of the AHU. The main frame work shall be with imported, extruded aluminum profiles. All sections are provided with hinge type access doors with handle & locking systems for easy access for maintenance. The blower section will have DIDW blower with backward forward curve impeller mounted on a common base frame with drive motor. The blower may be direct drive v-belt drive arrangement. Anti vibration mounting below the common base frame and outlet canvass connection at blower outlet will be provided to isolate the vibration of blower.

...more

Double Skin Air Handling Units

BATS offer Air Handling Unit in both options Single skin Construction and Double skin construction. Single skin constructed AHUs are to be used in Fresh air Ventilation System. Single skin constructed AHUs are built by using heavier gauge sheets (18 / 20 SWG Galvanized sheet). Double skin AHUs are constructed by using PUF insulated panels. The panel outer skin may be with 20/22 SWG GI sheet and the panel inner skin may be with 24 SWG GI sheet. PUF slabs will be used as core insulation of AHU panels. The thickness of panel may be 25 / 40 / 50 mm. Thickness of panel will be decided with application and size of the AHU. The main frame work shall be with imported, extruded aluminum profiles. All sections are provided with hinge type access doors with handle & locking systems for easy access for maintenance. The blower section will have DIDW blower with backward / forward curve impeller mounted on a common base frame with drive motor. The blower may be direct drive / v-belt drive arrangement. Anti vibration mounting below the common base frame and outlet canvass connection at blower outlet will be provided to isolate the vibration of blower. AHUs will have other suitable selected internals based on the application in combination of the following: Air intake louver (Fresh air / once through System) Return air mixing box (Recycling system) Strip Heaters bank Pre filter bank (10 micron) Cooling coil / Cooling pad Fine filter bank (5 micron) Super fine / HEPA filter bank (0.3 micron) Generally, Air Handling Units are classified as floor mounting and ceiling mounting based on the mounting arrangement. Available to suit to the application and to suit to the designed flow rate and static pressure as custom built. The cooling coil will be designed either Direct expansion / chilled water duty conditions based on the requirement. Based on your requirement, we can include instrumentations for monitoring and control the system performance and safety point of view like magnehelic gauges to measure pressure difference across the filters, limit switches on inspection door of AHU etc.

...more

Dispensing Booth

Generally used by all pharmaceutical companies when raw material needs to be sampled and dispensed within a clean environment. They are designed to provide operator and products protected from outdoor or external contaminations. The equipments designed in accordance with US FED 209 E standards. The equipment construction with SS 304 sheets. The lighting is provided on both side panels ensures shadow less lighting through the booth. The room air taken by a slotted air grill located at low level inside the booth with pre filter down to 5 micron and larger size particle. The filtered air is forced through a HEPA filter which creates a laminar floor effect of clean air on the work table surface to ensure required cleanliness level to meet the process. Separate electrical power switches is provided for supply air blower & lighting, additional power socket is provided inside to connect weighing scale. A megnehellic pressure gauge is provided to monitor the pressure drop across the HEPA filter. It is also constructed using epoxy powder coated galvanized sheets depending on the user specification. The general standard sizes are 4’x2’ & 6’x2’. It can also be made according to users requirement

...more

Cyclone Separators

Cyclonic separation is a method of removing particulates from an air stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate particle from the dust laden air. Cyclone Separators Cyclone body will be cylindrical in the top portion and conical shape at the bottom as shown in the drawing. The air stream will enter into the cyclone body tangentially in the top cylindrical with high velocity. The top portion of the cyclone body guides the air to move in circular pat in high velocity. A cyclonic effect (twister) will be created inside the body and the air stream move downwards in the heavier dust particles in helical pattern. The heavier particles in the air stream have too much inertia, while moving in cyclonic effect and move towards outer peripheral of the cyclonic effect in the air stream. When the particles are striking the inner surface of the cyclonic body, it will lose its momentum and fall down. In a conical system, as the rotating flow moves towards the narrow end of the cyclone, the rotational radius of the stream is reduced, thus separating smaller and smaller particles. Cyclone is called as pre collector in the dust extraction system. Cyclone has good efficiency in dust separation for large size particles and fiber dust particles. Cyclone separator will be used to segregation of items or products in the conveying systems. Cyclone separator MOC will be defined by the application and nature of dust to be handled.

...more

Room HVAC Systems

Clean room is an enclosed clean work space employing control over the particulate matter in the air with temperature, humidity and pressure control. All clean rooms must not exceed a particulate count as specified in the air. We are all aware that the times are changing in Indian industries in all sectors have to gear up to meet the new challenges of changing time. The manufacturing practices of the past are no longer considered good enough. The quality standards are being revised constantly to meet Indoor Air Quality (IAQ) The laminar air flow principle was introduced in clean room technology. This was considered to be the biggest revolution in clean room design engineering to maintain IAQ. GENERAL REQUIREMENTS Clean rooms to be built and operate in an area where particle generation levels are minimum. Environmental control Clean room air pressure Air changes rate of air flow Temperature range Humidity range Noise level Vibration levels Microbial Contamination Other factors like lighting, internal equipment load, occupancy, electromagnetic radiation, radioactive particles, gases, vapors. CLEAN ROOM DESIGN REQUIREMENTS Area to be defined to built clean room space. Entry ways Ante rooms, change rooms Air handling system with filtration Air-conditioning equipment Clean room furniture’s, equipments Clean room lighting and fire protection Desired level of cleanliness.

...moreBe first to Rate

Rate ThisOpening Hours