VAC-U-CHECK

Hydrogen is our friend or foe. Depending on the type of casting you produce, hydrogen absorption by molten aluminum can be helpful or harmful. With the Vac-U-Check you are assured a quick, simple, economical, and accurate method of monitoring the hydrogen level in your melt. A vacuum solidified sample exaggerates the hole size, making the analysis of gas in the sample easy to determine by visual methods or by using the specific gravity formula. The use of a Vac-U-Check unit is simple. Dip a 1/4 pound molten aluminum sample from your furnace. Place the sample in the vacuum chamber for solidification. After the sample is cool, saw it in half for a visual inspection or weigh the sample in air and water to determine the true specific gravity. Should your castings be at the premium level, a minimum amount of gas is required. If you are producing a commercial casting, a small amount of gas can be helpful in reducing shrinkage, thus simplifying gating, risering, chill usage, and improving yield. See the samples above and note shrinkage difference in the sample solidified in air.

...more

tilting machine

Tilt pouring reduces turbulence as molten metal enters the die cavity, provides shorter cycle times, and requires less metal for feeding systems. Aluminum castings produced in metal molds have a tighter dendrite structure than castings produced in other processes. In addition, aluminum castings are harder and have better pressure characteristics. Value added options, such as sand cores or cast-in ferrous inserts are quite simple.

...more

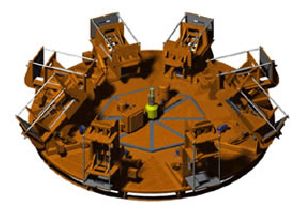

Tilt Pour Rotary Table

The Rotary Casting Machine advances permanent mold casting technology another step and makes it the most profitable approach for the modern foundries today. This high production, completely automated system can meet your needs for large volume applications. We incorporate up to 12 of our standard casting machines (#2H, #3HS, #6H or RT machines) on one rotary table to reduce cycle time in each station to as little as 20 seconds. As an example, based on our 8-station 2H Rotary Table, we have calculated that eight seconds is necessary to index the table between stations without inertial forces affecting feed characteristics of castings. Assuming a three minute (180 second) cooling cycle, this rotary system will theoretically produce 120 cycles per hour. At 83% of theoretical, it would be 100 machine cycles per hour. At 100 hours per week, this calculates out to 10,000 machine cycles per week. If there are two cavities, it will produce 20,000 parts week . This will give a total production of nearly one million parts per year!

...more

Test Molds

Test Bar Mold Complies with ASTM B108-02 CNC machined from class 30 gray iron. Optional digital temperature readout available. Portable Weight 150 lbs. (68 kg) Spectrographic Coupon Mold CNC machined from A36 steel Heat dissipating handle Homogeneous element distribution within the sample. Depressed center to aid lathe machining Easy sample removal Portable Weight 7 lbs. (3 kg)

...more

Swing-In Casting Catchers

casting catchers increase production while reducing operator load. They are a available as manual swing-in or fully automatic powered swing-in. The table height is optimized to allow the operator to inspect a casting while the next casting is cooling in the mold. The system utilizes minimal floor space and allows one operator to do the job safely with minimum effort. Tie bar extensions are required when using a swing-in casting caster. The table height on all swing-in casting catchers is adjustable in 1.5 inch increments. Rotary action of the powered casting catcher is from a hydraulic rotary actuator. The stroke of the vertical cylinder is eight inches.

...more

ground ejector pins

Stahl centerless ground ejector pins are made from high carbon steel from durability in operation. Two semi-finished hex nuts and two semi-finished hex jam nuts are furnished with each pin. For applications that require longer lengths or where rigidity is considered important we suggest the use of Stahl standard stock extensions for ejector pins. Please refer to the Typical Permanent Mold Assembly sheet and individual catalogue sheets for all your permanent mold component requirements.

...more

Slide-In Casting Catchers

Features Produced for use with Rotary Table or individual machines, with or without power unit. Both styles use aluminum bronze vertical way bars. Linear ball bearings and 2.00" dia. induction hardened chrome plated way bars used for horizontal travel. Use of hydraulic cylinders for vertical & horizontal travel. Vertical and horizontal travels are adjustable with on board limit switches.

...more

RT Machine

CMH Manufacturing Co. introduced a new twist on the reverse tilt process at the CastExpo. Our static cylinder head machine inspired the development of the HALL RT2H. The machine has twin opposing rams and a lower cylinder that can be programmed as a pull or an ejector. The ram cylinders each have 15” stroke and the distance between the platens when both rams are open is 42” and with both rams closed the distance is 12”. The maximum clamping force is 29,000 pounds. The stroke on the pull/eject is 4” with pulling force of 16,200 pounds and pushing force of 18,500 pounds. It is available with standard or proportional tilt.

...more

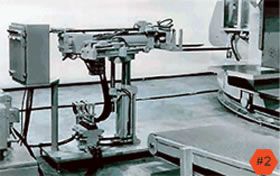

Robot Casting Catcher

Robot Casting Catcher Features In keeping with our continued commitment to meet the needs of our customers and offer accessories that lend efficiency and increase production rate, we have developed our robot casting catchers. Ejected castings can be removed from the upper or lower mold halves with precision and placed on our indexing cooling conveyor, dropped into a tote box or a quench tank, depending on your requirements. Though the robot was originally designed for our rotary machines, it can interface equally well with any of or individual machine applications. Our robot is operated by an internal programmable controller and all strokes are set with adjustable limit switches. Each cylinder is cushioned on both ends providing a smooth transition of movement. The standard sequence of operation is to extend into the mold, lift or catch the casting, retract out of the casting machine, rotate 90 degrees, lower, tilt the forks to slide the casting onto the indexing/cooling conveyor and return to start. The conveyor indexing rate and spacing are adjustable with a timer. Optional applications for this robot include core setting, transfer to and from other processing equipment, etc.. An optional mechanical hand is also available.

...more

Reverse Tilting Permanent Mold Casting Machine

Low maintenance due to few moving parts, heavy duty, rugged, and dependable. Unique design allows the mold to be poured while the parting line is perpendicular to the floor. The Machine tilts the mold so that the parting line is parallel to the floor for solidification and ejection. Cushioned tilt cylinder provides a smooth tilting motion from start to stop. Twin ram cylinders provide a safety factor, as well as extra holding pressure and better clamping balance. Integral lower eject is included.

...more

Stahl return pins

Stahl return pins are fully machined from carbon steel utilizing an improved forged heat. Each return pin is furnished with two semi-finished hex nuts and two semi-finished hex jam nuts. For most molds mounted in 18 x 24 or smaller machines we recommend 1/2" diameter return pins. For molds being mounted in 30 x 30 and larger machines we recommend 3/4" diameter return pins. Please refer to the Typical Permanent Mold Assembly sheet and individual catalogue sheets for all your permanent mold component requirements.

...more

Remanufactured Equipment

Times are tough for permanent mold foundries needing to replace a tilt machine. Have you considered having HALL do a complete factory remanufacturing of your existing tilter or perhaps factory rebuilt used equipment? Here is an example of one of our customer's factory remanufactured 3L machine (right). We salvaged the steel and replaced worn components with new cylinders, bearings, bushings, way bars, and slide wear strips.

...more

Programmable Tilt Power Units

The Programmable tilt system is designed for applications that require variable tilt rates. Variable tilt rates can increase your profitability by: Improving Yield Improving Metal Flow Reducing Air Entrainment of the metal in the metal stream Reducing Inclusions Reducing turbulances as the metal enters the mold The system uses our time proven hydraulic power unit. Refer to Hydraulic Power Units pages for standard unit details. The system uses a PLC control and a touch screen operator interface. The unit can be configured to fit almost any application, but most systems are six valve. Normal circuits include tilt, ram, front eject, core, casting catcher in/out and casting catcher vertical movement. The proportional tilt valve is PLC controlled with feedback from a trunnion mounted potentiometer or optional ultra sonic sensor on the casting machine. Tilt rates are programmed by drawing the desired ramp curve on the touch screen with your fingertip. The PLC can store up to eight different ramps under a four digit code. All manual functions are included on the touch screen and touch screens are available in monochrome or color.

...more

Pouring Cups

Pouring cups are made from 30 class gray iron. The pouring angle is 45°, so that the mold filling is complete at 45° of machine tilt. Whether used with programmable tilt or standard tilt, these cups produce quality permanent mold castings.

...more

pouring cup

Pouring cups are made from 30 class gray iron. The pouring angle is 45°, so that the mold filling is complete at 45° of machine tilt. Whether used with programmable tilt or standard tilt, these cups produce quality permanent mold castings.

...more

Oversize Mount Plates

Oversize mold mount plates should be used when additional mold mounting surface is needed above or below standard mount plates. (See separate catalogue sheets for Standard Mold Mount Plates). Mold mount plates are fully machined and ground on all surfaces from carbon steel plate. Please refer to the Typical Permanent Mold Assembly sheet and individual catalogue sheets for all your permanent mold component requirements.

...more

Non-Tilting Rotary

Indexing system uses a Geneva drive with an epicyclical gear motor and a variable frequency invertor. This allows smooth indexing speed adjustment. Control utilizes the Allen Bradley SLC series PLC and a color touch screen. Easily interfaces with ladler or casting catcher.

...more

Mounting Rails

Do you have existing molds that run on an Autocast mount rail machine? CMH can adapt our time proven #6H to run these molds with more stroke and ejection clearance than the original Autocast machines. See #6H, traditional tilting machines, for machine specifications. Replacement mount rails and spacers * Mold mount rails and keys are designed for mounting permanent molds in - 30 x 30in (762 x 762mm) - 36 x 36in (914.5 x 914.5mm) - 42 x 42in (1066.8 x 1066.8mm) - 48 x 60in (1219.2 x 1524mm) tiltpour casting machines.

...more

mounting plates

Standard size Mount Plates are used for mounting permanent molds. However, if larger size mount plates are needed we suggest you consider our oversize mount plates which are designed for "extra long" molds. Oversize Mold Mount Plates should be used when additional mold mounting surface is needed above or below standard mount plates. Mold Mount Plates are fully machined and ground on all surfaces from carbon steel plate.

...more

Mount Spacers

Mold mounting spacers are accurately machined from cold drawn seamless steel tubing. Any length mold mounting space can be obtained by different combinations of stock spacers. For spacer lengths of 6" or less we recommend the 1 1/4" O.D. size with 1/2" mounting bolts, over 6" we recommend the 2" O.D. with 3/4" mounting bolts. Please refer to the Typical Permanent Mold Assembly sheet and individual catalogue sheets for all your permanent mold component requirements.

...more

mold making machine

Roll-over design utilizes smaller floor footprint and allows pouring and ejection at different work stations, facilitation in line work flow. Low maintenance due to few moving parts, heavy duty, rugged, and dependable. PLC/Touchscreen control, hydraulic power unit is sized to operate at a medium operating pressure. Twin cushioned tilt cylinders provide a smooth tilting motion from start to stop. Quad ram cylinders provide a safety factor, as well as extra holding pressure and better clamping balance. Hydraulic ejector system available. System can be interfaced with other devices such as Robot Casting Catcher and automatic ladler.

...more

Manual Hydraulic Power Unit

power units are designed to operate each of our Permanent Mold Casting Machines with optional accessories in manual or automatic mode. Timing for pouring and cooling are controlled for repeat production without variance. The hydraulic pump is variable volume/pressure compensated, and coupled directly to the TEFC electric motor. Standard configuration is with 4 adjustable timed functions and 4 valves to control tilt and ram, as well as core pulls and / or ejectors. Our automatic control unit is a PLC controlled system which offers easy repair for any maintenance crew. The reservoir is fitted with an air cooled aftercooler and system includes a separate recirculating pump to reduce heat build up and maintain reasonable system temperatures under severe service conditions. This adds significantly to the pump life and reduces down time. We incorporate the latest and most innovative designs to increase your production and profits by reducing your labor.

...more

Lubricant

CMH recommends that you lubricate your waybars weekly with a dry lubricant such as Dri-Slide is a formulation of Molybdenum Disulfide and Graphite with rust and corrosion inhibitors. Features No oily or greasy residue Wide Temperature range Contains corrosion inhibitors Low viscosity carrier Contains no ozone depletes Available in plastic bottles or aerosol can

Appearance Rating : Black Liquid

Specific Gravity : 0.86

Flash Point : 114°F (45.6°C)

...more

Alloy Steel Leader Pins

Stahl precision ground and hardened alloy steel leader pins are specifically designed for use in permanent molds to provide accurate alignment between the mold halves. With the use of a retaining bolt and specially designed shoulder you are no longer faced with the problems associated with a press fit type of leader pin. With diameters from .500" to 1.000" these pins are designed to be used in the construction of both small and large permanent molds. Please refer to the Typical Permanent Mold Assembly sheet and individual catalogue sheets and individual catalogue sheets for all your mold component requirements.

Country of Origin : India

Type : Alloy Steel Rods

Material : Alloy Steel

...moreBe first to Rate

Rate ThisOpening Hours