Triple Die Paper Plate Making Machine

222,000 Per Piece

Tubular Spine Grid Cutter

35,000 - 35,000 Per Piece

01 Piece (MOQ)

Best Deals from Casting Machine

Piston Die Casting Machines

1,000,000 - 2,000,000 Per Nos

Wet Cast Plant

Get Price Quote

Parijatha Machinery has developed the Wet Cast Products manufacturing line using Rubber, FRP or Polyurethane Moulds. The System is designed for mass producing Wet Cast Products which normally required lots of manual work.This System comprises of an Automatic Dosing Device which is fixed on to a Hopper on which the mixed material from the Mixer is poured.Variable dosing of material depending upon the mould size and type programmable to meet all requirements using PLC Control. Automatic movement of the Pallets clamped pneumatically to the sturdy table on which the heavy duty vibratig devices are fixed. Hydraulic movement of the Pallets for very smooth operation on to multiple vibration stations for superior compacted concrete products.Automatic stacking of the Pallets using the unique Pallet Handling System with the finished products handled from a low level for operator safety and ease.Vibrator Table for Wet Cast Tiles : Unique design developed specifically for Wet Cast Tiles. Easy to Clean and maintain, no possibility of blocking of holes. Can be used in combination with Parijatha Planetary Mixer PM-150 for both Top Mix and Back Mix. Very Sturdy and Robust Construction for long life. Very low Power requirement – 1 H.P. per Table. Size : 1000 mm x 2800 mm.

double die machine

Get Price Quote

Backed by our team of dexterous professionals, we have emerged as a distinguished Manufacturer, Trader and Exporter of Double Die Machines from Karnataka. The Double Die Machines we make available are manufactured in compliance with set industrial norms. To meet the bulk and urgent requirements of the buyers, we maintain a large stock of the Double Die Machines within the promised time frame.

Wirtz Automotive Gravity Casting Machine

Get Price Quote

1 Piece(s) (MOQ)

We offer Wirtz Automotive Gravity Casting Machine. The Wirtz Models 4040C are high speed gravity grid casters designed with state of the art controls and technical enhancements. Casting efficiency is provided by electric mold heat, greatly improved temperature controls, and our non-recirculation lead delivery system (LDS). Electric Mold Heat is applied to both the moveable and stationary halves of the mold by cartridge heaters. Automatic temperature controllers monitor the temperature settings of the mold, ladle and feed line. Any fluctuation in these temperatures is automatically corrected. The lead delivery system (LDS) has been drastically improved because the LDS does not use a return lead trough. This system flows from the lead furnace to a dispensing valve where an adjustable amount of lead is allowed to enter the ladle after each pour. Dross is controlled with gas shielding, ladle covers, and drip bars.

Automatic Grid Casting Machine

850,000 Per Piece

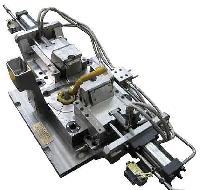

Swing-In Casting Catchers

Get Price Quote

casting catchers increase production while reducing operator load. They are a available as manual swing-in or fully automatic powered swing-in. The table height is optimized to allow the operator to inspect a casting while the next casting is cooling in the mold. The system utilizes minimal floor space and allows one operator to do the job safely with minimum effort. Tie bar extensions are required when using a swing-in casting caster. The table height on all swing-in casting catchers is adjustable in 1.5 inch increments. Rotary action of the powered casting catcher is from a hydraulic rotary actuator. The stroke of the vertical cylinder is eight inches.

Automatic Paper Die Cutting Machine

Get Price Quote

Performances and applications1. Product, high technical assurance, each performance index has exceeded the level of other counterparts.2. Load material: Electric roll material loading, which is easy and fast.3. Feed material: the photoelectric eye tracking system assures the synchronization of material feeding and die-cutting speed. Automatically fold and flatten the cornering materials at the paper core. It realized the multistage adjustment of the folding degree. No matter how bent the product is, it can be flatten or refolded towards other directions.5. It can die-cut according to the printed words and figures or simply die-cut without them. The coordination between stepping motor and photoelectric eye which can identify colors assures the perfectly fit of the die-cutting position and figures. Simply set the feed length through the micro-computer controller To die-cut the products without words and figures.6. Die-cutting area: 900mm*400mm. (it can also be tailored according to the customers’ requirements)7. Maximum die-cutting speed can be up to 9000 times/h, which indicates the significant high production efficiency.8. The die-cutting force is provided by a 7.5kw inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.9. Adapt flat bed die-cutting mode, and the cutting boards are extremely cheap.10. The oscillating lower cutting board makes the die-cutting process more steady compared to other similar products and magnificently increased the service life of the cutting board.11. Finished products are pulled out by two rollers. Comparing to other similar die-cutting machines which need extra press cutter to cut the joints, our machine can not only save the cost of press cutters of each machine, but also avoid the troubles of installing and debugging the press cutters, which can magnificently save time. Especially, it can assure better quality of the product appearance when the die-cutting without joints can be realized under many conditions.12. By the action of the entity induction switch, finished product will be automatically lowered down to remain the height of the pilling paper unchanged, during the whole die-cutting process, manual paper-taking is not needed.

Yizumi Cold Chamber Die Casting Machines

Get Price Quote

Offered machine is fabricated utilizing fine quality material which we acquired from the trusted and driving sellers of the market. These have control to finish summon over nature of castings delivered.Its features are ; 1.High strength 2.Long functional life 3.Wear and tear resistant

Automatic Grid Casting Machine

Get Price Quote

the machine is fully automatic and can produce up to 10 trimmed grid panels per minute depending upon the lead alloy and the grid design. This equipment is ideal for high volume production battery and battery plate manufactures. The construction of machine is rugged and built for low maintenance. The grid mould opening – cum closing cum grid ejection and ladle tilting is pneumatically operated. Grid alinging chute, grid-trimming device, grid stacking mechanism are all operated by mechanical cams. Heating is by electrical resistance heaters (also given provision for additional heating by lpg at the gate of the ladle). The operations are simple and easy. the machine is fully automatic and suitable for any alloy. built in trim scrap conveyor trimmed grids are stacked for easy removal digital temperature controllers for better monitoring & control casting thickness 1.4 to 4 mm maximum casting size including lugs – 350 x 150 mm power : 415v, 33kw (electrically heated furnace) / 15kw (diesel or lpg heated furnace) capacity : 8 to 14 grid pannels per minute furnace : 800 kg

Pellet die Making Machine

Get Price Quote

DIE CASTING PLANT

Get Price Quote

Die casting is an efficient manufacturing process used to mass-produce parts in a wide range of shapes, and these parts make their way into common items in our homes and workplaces. Die casting delivers a reliable process with a smooth, quality surface that won’t need any additional polishing or tooling. The two most common methods of die casting are hot chamber and cold chamber. Learning the difference between these two options can help you evaluate and take the right decision according to the needs. Hence, If you are interested in starting a new die casting project, it is best to involve our team of engineers early on to utilize our expertise. Since each project is different, we can recommend the best material and process for your project.

pressure die casting machines

1,200,000 Per Piece

We are offering pressure die casting machine is hydrualically operated machine to cast tubular grids used in tubular inverter traction batteries. This is fully automatic in nature and can give strong tubular grids.

Horizontal Cold Chamber Pressure Diecasting Machine

Get Price Quote

Diecasting Machines cater to a wider range of applications. From simple components to high precision industrial components these machines take care of most diecasting needs.offers a range of nine models with locking forces ranging from 80 to 1100 tonnes to cover a wide range of pressure diecasting of aluminium and zinc components.Built to high quality standards, these machines are subjected to stringent performance testing using advanced testing devices to ensure high performance, increased productivity and reliability.The salient features of these machines include double toggle mechanism with setting of die closingopening and ejector speed, flying piston type accumulator, large adjustable opening stroke and programmable logic control.

Semi Automatic Ultrasonic Die Polishing Machine

Get Price Quote

Casting Machine

60,000 Per Piece

SS Vacuum casting machine

200,000 Per Piece

Gravity Die Casting Machine

Get Price Quote

Double Die Paper Plate Making Machine

Get Price Quote

7 Hills Groups is an esteemed Manufacturer and Supplier of Double Die Paper Plate Making Machine. With our advanced Double Die Paper Plate Making Machine, the use can get paper plate size between 4 inches to 16 inches. The machine can efficiently make paper plates with paper weight from 80gsm to 1000gsm.

Fully Automatic Single Die Paper Plate Making Machine

Get Price Quote

Semi Automatic Double Die Machine

plastic die maker

Get Price Quote

plastic die maker, Casting Dies, Embosing Block Dies

Wet Cast Plant

Get Price Quote

Parijatha has developed automated systems for manufacture wet cast products using Rubber, PVC or Polyurethane Moulds manufactured as per customers requirements and designs by our own design team and tool making division.

Pressure Die Casting Machine

Get Price Quote

Pressure Die Casting Machine

Gold Jewelry Casting Machine

Get Price Quote

Gold Jewelry Casting Machine, silver jewelry casting machine

horizontal cold chamber pressure die casting machine

Get Price Quote

horizontal cold chamber pressure die casting machine, vmc with linear motor

dies making machines

Get Price Quote

dies making machines, plastic injection molding components, Electric Tools

die cast tools

Get Price Quote

die cast tools, mould refurbishment, injection mould maker

low pressure die casting

Get Price Quote

low pressure die casting, Precision aluminium, Pressure Die Casting Products

Die Cutting Machine

Get Price Quote

Precision Components, offset printing machine, printing machine spares