Magnetic Chip Conveyor

50,000 - 500,000 Per Piece

1 Piece (MOQ)

Magnetic chip conveyors are intended for ferrous material applications with small chips. the chips fall on to the conveyors stainless steel surface and are conveyed by powerful magnets moving underneath. The chips are released from the magnetic at the discharge end, and fall freely into a collection container.

Magnetic Chip Conveyor

Get Price Quote

In order to ensure zero defects at buyer's end, we make sure that we conduct stringent quality procedures. We have installed all the requisite amenities, necessary for making safe side deliveries.

Best Deals from Chip Conveyors

Chip Conveyor

120,000 Per Piece

Chip Handling System

500,000 Per Piece

Chip Belt Conveyor

Get Price Quote

We offer exquisite range of Chip Belt Conveyor that is highly cost effective. It is used for the universal transport solution for applications where no cooling lubrication is present also for parts with sharp edges but not for hot chips. However, other parts can also be transported, such as waste parts from plastic injection machines. We provide Chip Belt Conveyor to the clients as per their requirements along with the timely delivery within stipulated time period. Features : Oil and grease resistantStrongEfficient performanceLongevity Uses : On punch-nibbling machinesFor transporting punching scrap Punching trimmings

Magnetic Chip Conveyor

1,000,000 Per Piece

Chip Conveyors

Get Price Quote

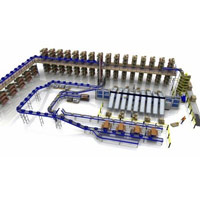

CHIP CONVEYORS separate the chips from the coolant / oil and transfer the separated chips to a chip bin. WE MANUFACTURE DIFFERENT TYPES OF CHIP CONVEYORS NAMELY: Scraper type chip conveyors: Here scrapers are used to scrape the chips from the bottom of the conveyor, push them to the top of it & make them fall into a chip bin, thus separating them from the dirty coolant. These are used to separate steel or cast iron chips with more of flakes & less of tough coils. Scraper type chip conveyors with Rotary drum: This conveyor is generally used to filter Small Steel or Aluminium or Cast Iron chips / particles from the coolant / oil. The floating chips are made to settle down inside the conveyor by making the coolant pass through a rotary drum ( OD to ID ) wound with filter mesh, wherein the chips get arrested and only the clean coolant comes out. As the coolant level goes down, the chips settle down & the scrapers scrape the chips to the top & make them fall into the chip trolley. Here the chips are not only separated, but even the coolant is also filtered. Slat chip conveyors: This design of chip conveyor is used to separate coiled chips from coolant / Oil. The coiled chips are carried away by the slat belt that moves up & makes the chips fall into the chip bin. Magnetic chip conveyors: This conveyor finds its application in separating small ferrous chips from coolant / Oil . There is a polished SS top surface on which the coolant with chips falls. Below this surface a magnetic belt moves. As the magnetic belt moves up, the chips also move up & fall into the chip bin.

Chip Conveyor

Get Price Quote

Chip Conveyor, Leak Testing Machine, Duplex Bag Filter, multi bag filter

Chip Conveyors

Get Price Quote

V C Filters and Fabricators is one of the leading manufacturing & supplying company of high quality chip conveyors in India.

Magnetic Chip Conveyors

Get Price Quote

Magnetic Chip Conveyors, Grease cartridge, Filter Media

Hinged Belt Chip Conveyor

Get Price Quote

Hinged Belt Chip Conveyor, Fanuc Robodrill Machine Coolant System

Chip Conveyor

Get Price Quote

Chip Conveyor, Electric Protecting Equipment, Engraving Machine, Apron

Chip Conveyor

Get Price Quote

Chip Conveyor, Machine Tool, Machine Guards, coolant tank assembly

Chip Conveyor

Get Price Quote

Chip Conveyor