HMT Drilling Machine Spare Parts

5,699 - 8,930 Per Set

1 Set (MOQ)

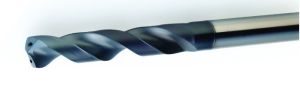

IN Plus Inox Drill

200 - 3,000 Per Piece

50 Piece (MOQ)

Best Deals from Concrete Coring Machine

Pillar Drilling Machine

90,000 Per Piece

Brazed Carbide Trepanning Tool

2,900 Per Piece

10 Piece (MOQ)

eifco drilling machine

Get Price Quote

Cylindrical Grinding HMT Dia 30 Max Cylindrical Grinding HMT Dia 30 Max H.Cylindrical Grinding GMT Dia 75 Max H.Cylindrical Grinding GMT Dia 75 Max Surface Grinding EIFCO 200x400mm Surface Grinding EIFCO 200x400mm Universal Milling BFW 1.5 Series Universal Milling BFW 1.0 Series Horizontal Milling BFW 1.0 Series Center Lathe KIRLOSKAR 1335 Entrepurner Mini Lathe PROTEL 14 Dia Column Drilling EIFCO 25 Dia Column Drilling EIFCO 25 High Speed Drilling EIFCO 6.35 mm Bench Drilling EIFCO 20 Dia Bench Drilling EIFCO 20 Dia Shaping Machine ELGI Bench Grinding AVRO 1HP Jib ACE 500 KG Hand Pallet Truck ACE 2 TON Air Drier SANPAR 5 Bar Fettling Machine EIFCO 1hp Punching Machine PROTEL 1 TON Air Compressor ELGI 5 HP Diesel Generator A.LEYLAND 100 KVA Column Drilling EIFCO 25

Drill Bushes

Get Price Quote

We are reckoned as reliable Drill Bushes Manufacturer and Supplier in Bangalore. Drill Bushes, offered by us, is made in conformity with international standards. Our Drill Bushes are made with aluminium, Iron, brass, etc. Drill Bushes that we offer can be designed and developed as per mentioned specifications of the clients. Highlights Robust construction Rust-resistant Reliable Several sizes available

Multi Spindle Drilling Machine

Get Price Quote

We are offering premium quality Multi Spindle Drilling Machine, which is widely used for drilling in Railway Track plates and for many other applications. Our Multi Spindle Drilling Machine is widely demanded by auto industries for its accurate operations, durability, easy usage, high performance and low power consumption. This Multi Spindle Drilling Machine is vital in 4 Drilling at same time to 4 identical samples up to Drilling size of Diameter 27mm. Why Our Multi Spindle Drilling Machine? Background of machine is having good made-up base and two rigid vertical fabricated columnsTough guide ways to fixed both the columnsThe Drilling Head's is placed on the guide waysThis machine operates on its fed time as operation starts when both the Drilling Head's are moving down with cutting speedElectrical controller is there with operating pendent Coolants pumpJob fixing fixture is available with locating pin helps in giving accurate location to the work piece and operator timeHigh speedHigh durability

Pcb Drilling Machine

Get Price Quote

We make available, the high-power PCB Drilling Machine, which has the power of approx 60,000 rpm, with auto speed adjuster. We have ultra-modern packaging systems available to keep the products safe from physical factors that may damage the product to some extent. Thus, we only use qualitative packaging material. Our company is a pioneering name in Bengaluru(India), renowned for providing the best product at competitive prices.

Vacuum Degasser

Get Price Quote

Drilling Tools

Get Price Quote

Only premium packaging material has been used for the safe packing of our products which ensures that only defect-free range is delivered at buyer's end. Adequate packaging assures the safe transit and flawless delivery. Association with trusted vendors enabled us to meet the quality expectations of the clients. We source only premium-grade raw materials from the reliable sources after complete checking.

Integral Drill Rod

Get Price Quote

concrete core drilling equipment

Get Price Quote

Offering you a complete choice of products which include impact echo systems such as impact echo systems - wireless kit and concrete road & floor profiler.

angle head

Get Price Quote

Angle head, Wohlhaupter is a reputed tooling manufacturer of more than 86 years old, and are located at Stuttgart and any innovations they make in tooling are tried and tested in automotive firms like Mercedes Benz, Volkswagon, and BMW & Robert Bosch.These are tried and tested toolings and are the ones being supplied to Indian Customers.

Pneumatic Crawler Drill

Get Price Quote

Diamond Core Drills

Get Price Quote

Usage For Marble, Limestone, Sandstone, Granite, Concrete, Refractory and Asphalt Manufacturing Segments are produced from latest machineries and technology from Germany Features High production, fast drill and extended life with economical purposeWet cutting and dry cuttingWide range of critically hard materials with steel reinforcing and for providing the lowest cost per hole, also for brick and block, long life and maximum penetration.

Tapered Drill Rod

550 Per Piece

1 Piece (MOQ)

Multi Spindle Drilling Machines

Get Price Quote

Our high speed Multi Spindle Drilling Machine performs riveting operation on various rivets at a time. Multiple Spindle Drilling Machine offered by us is a blend of performance with accuracy. Robust construction of our Multiple Spindle Drilling Machine assures long lasting performance. We are counted among the key Horizontal Multi-Spindle Drilling Machine Exporters in India. Click Here To View Technical Detail

Drilling Machine

Get Price Quote

A drill or drill motor is a tool fitted with a rotating cutting tool, usually a drill bit, used for drilling holes in various materials. The cutting tool is gripped by a chuck at one end of the drill and rotated while pressed against the target material. The tip of the cutting tool does the work of cutting into the target material.

Pcb Drilling Machine

Get Price Quote

We are the main supplier of this product.

Rock Drilling Machine

Get Price Quote

The joints are friction welded to achieve maximum strength, and the threads of the end-pieces are heat treated for optimum durability and strength of the thread profile. This not only ensures long thread life, but also makes coupling and uncoupling quick and simple, reducing drilling time.

Drill Sleeves

Get Price Quote

Jig Bushes

100 Per Piece

50 Piece (MOQ)

Back Geared Auto Feed Pillar Drill Machine

Get Price Quote

Specification of - P40AA and P40BA - Column Drill Machines: Description P40AA P40BA Capacity Drilling In M.S. 40 40 Drilling in C.I. 45 45 Tapping in M.S. 25 25 Rough Boring M.S. 75 65 Drilling Head Drive of the Spindle 9 Speed Oil Bath Gear Box 4 Step Cone Pulley and Back gear Type Spindle Hole Taper MT-4 MT-4 Spindle Travel 250 250 Spindle Speed (RPM x Steps) 88-1404 x 9 80-2600 x 8 Diameter of RAM 78 78 Auto feed Range ( mm / rev) 2 / 0.05 & 0.09 2 / 0.05 & 0.09 Working Range Max. Distance Spindle Nose to Base 920 920 Distance Spindle Nose to Table 530 530 Distance Spindle Center to Column 345 345 Table Size 450 x 455 450 x 455 Machine Measurement (L x B x H) 880 x 675 x 1850 880 x 675 x 1850 Diameter Of Column 130 130 Power Motor 2 HP/ 3 HP 2 HP V-Belt B-33 x 2 B-79

Diamond Core Drill

15,000 Per Piece

1 Piece (MOQ)

Special Purpose Machine

Get Price Quote

SPMs or Special Purpose Machines offer tremendous scope for high volume production at low investment and at low cost of production when compared to CNC machines. SPM, Special Purpose Machines is a high productivity machine, with specially designed tooling and fixture, dedicated for mass producing the same component day in and day out. A judicious combination of limit switches, sensors, logic controls, automatic job clamping etc is the essence of a SPM. A well conceived Special Purpose Machine finds ways and means to utilize the man and machine to the optimum. We offer low cost dedicated SPMs for mass production of small components of 2 & 4 wheelers, tractors, trucks, engines etc. Typical components are rear wheel flange, shifter cam, shifter fork, clutch sleeve etc. OUR SPMs ARE SUITABLE FOR MASS PRODUCTION OF COMPONENTS WHICH INVOLVE OPERATIONS LIKE TURNING, BORING, FACING, DRILLING, REAMING, TAPING, CHAMFERING ETC. Our Special Purpose Machines work with 4 to 8 stations, depending upon job requirements. Most of the Special Purpose Machine concept is standardized which enables very fast delivery of the machine. Please send us your enquiry with the following details for enabling us to send you our offer: (a) Job drg (b) Job material (c) Operations to be carried out on the job to be clearly indicated in the drg (d) Desired rate of production (e) Precondition of the job as presented to the machine

4 Spindle Gun Drilling with Autoloader AND Counter Rotation

Get Price Quote

Hydraulic Borehole Wagon Drill

Get Price Quote

crawler drill

Get Price Quote

The Hydraulic Top Hammer drilling machines from FRD provides the best technology available to drill faster, at the least cost per tonne.If you have the job and the volume, we have the machine to stand up to it.

HL512 hdd machine

Get Price Quote

FEATURES OF CBU:Integrative layout design provide a nice apperance with advanced auto change drill pipe function and electron-hydraulic technology. ANCHOR SYSTEM:Hydraulic driving anchor boit help easy machine position. ENGINE:Turbochanging engine provides CUMMINS 4BT power, reliable performance and low oil consumption, suitable for most rough working condition. ENGINE COVER:Fiberglass rainforced plastic engine cover could be lift, making maintainence are easy work. DRILL PIPE BOX:Equipped drill pipe box contain 50 pics for the auto changing pipe system. CLAMP:Opening design clamp could be observed directly and make drill pipe changing easier. RUBBER TRAWLER BELT:Bridgestone brand rubber track and nine support wheels make zero harm to road. OPERATION TABLE:Rotatable chair and ergonomics layout design of opertation table provide a comfortable operation. DRILL PIPE CHANGING SYSTEM:Electron- hydraulic control pipe changing system help the operator one slight press to finish all the hard drill pipe changing work.

Drilling Machine

Get Price Quote

. Maximum drilling: DIA 38mm . Spindle centre to column: 450mm