Conveyor Spare Parts

Get Price Quote

We have a strong security system that helps us to make online transactions possible without getting worried about the security. You need to share your details with us and we make sure that the details are kept confidential. We are a quality centric organization, offering the best-in-class products that are manufactured using the experts approved and certified raw material procured from reliable sources. Features : Rugged construction High grade metal Long life & affordable

Wire Mesh Conveyor Belt

1,000 Per Meter

200 Meter (MOQ)

Best Deals from Conveyor Components

Rubber Conveyor Belt

Get Price Quote

We deal in Rubber Conveyor Belts of premium quality which are used frequently for various industrial purposes. These are made from hi-grade materials that resist adverse conditions and have durability and flexibility. Rubber Conveyor Belt are suitable for most of the industrial application purposes.

Cleated Belt Conveyor

225,000 Per NOS

Liquid Line Magnetic Trap

10,000 Per Piece

aluminium rollers

Get Price Quote

We have achieved great heights of success by providing top-notch array of Aluminium Rollers. We are comfortable with traditional payment options as well as the modern ones. Our payment related policies are client friendly. Our payment procedures are transparent, safe, and secure. These Aluminium Rollers, made available by us, are in conformance with the set industrial standards.

Magnetic Separator

Get Price Quote

Magnetic Separators can very effectively separate Iron/Ferrous particles from any material within its range. MCI has supplied Magnetic Separators to several thermal power stations in India (NTPC, PSEB, TATA POWER etc). Many magnetic separators are supplied to chemical, food processing industries, ceramics, silica, quartz, glass chips and glass raw material industries. Sugar Plants, etc. There are various methods by which tramp iron particles can be separated from raw material. They can be either electromagnetic type or permanent magnetic type. The various types are listed below:

Magnetic Separator

Get Price Quote

Avail from us Magnetic Separators that are manufactured in compliance with industrial standards for separation of fine ferrous contaminants. The Magnetic Separator is designed for providing a barrier against the material conveyed by means of self-cleaning and is mounted over the frame using eye bolts. The contaminants are conveyed to the conveyor’s side and discharged to the bins by cleared bins. We also manufacture Cross belt Magnetic Separators that can be mounted in a perpendicular manner above parallel pulley. Salient Features Adjustable feed rateWear and tear resistantStrong constructionCorrosion resistant Components Comprise conveyor beltsAdjustable take-upsRugged steel channel frameShaft mounted speed reducer with direct drive motor

Conveyor Chains

Get Price Quote

We offer Conveyor Chains for smooth and stable flow of material depending on their performance. These chains are available form 1” pitch to 24” pitch having breaking load up to 100 tones in carbon steel, stainless steel, zinc plated, nylon rollers, etc. These chains are used in steel plants, cement plants, process industries, furnaces etc.We are leading manufacturers and suppliers of Conveyor Chains. Features: Quality tested Longer operational life Require less maintenance

Heavy Duty Belt Conveyor

200,000 Per Piece

chevron conveyor belt

Get Price Quote

Chevron belting is used to convey materials at angles that are so steep that load slips on such belts make increased angles of inclination possibCleat height range from 3 mm to 50 mm le compared with smooth surface belts.

SCREW FEEDER

Get Price Quote

We are offering screw feeder. Aircon provides a wide range of screw conveyors that are suitable for the tasks of elevating, distributing and retrieving a remarkably broad range of bulk material. Requiring minimal floor space, these screw conveyors are ideal for elevating highly abrasive material without causing any damage. features: •high tensile strength •durable performance •high functionality •corrosion and abrasion resistant

Powered Roller Conveyor

35,000 Per Piece

Steel Conveyor Wheel

Get Price Quote

This series is universally applicable, can be used in freezer areas and as side guide wheel. The steel conveyor wheel excels with its high load capacity, robustness at high and low temperatures as well as good running stability. Hardened ball running surfaces ensure a long service life.

Magnetic Separator

Get Price Quote

Wet Low Intensity Magnetic SeparatorThe Wet Drum Magnetic Separator is a low intensity separator used in the recovery of magnetic susceptible material from non-magnetic susceptible material - primarily Magnetite and Ferrosilicon - in dense media applications. The unit is most effective in a Primary application with high throughput and recovery.Wet Drum Separators find use in a wide variety of applications like magnetic media recovery, purification of solids carried in liquid suspension and iron ore concentration.We offer two types of Magnetic Separators based on the nature of magnetic circuit. They are:Interpole: This design offers the magnetic circuit in an axial interpole configuration with alternating polarity and helps in obtaining a clean magnetic concentrate. The Interpole Magnetic Separator is available in drum diameters of 380, 610, 760, 915 & 1220mm and in widths ranging from 305mm to 3050mm, in increments of 305mm.Maltipole: This design has magnets arranged in a radial circuit and offers very high flux concentrations. Ideal for heavy media recovery applications, these drums are usually 915mm in diameter and are available in widths ranging from 305mm to 3050mm in increments of 305mm.

pcb conveyor

60,000 Per Piece

Weigh Feeder

Get Price Quote

Movement of bulk material is an essential feature in modern industrial processes. The simplest and fastest mode of transportation of such material is to convey them over a moving belt. In this operation the precise weighing of material, as it moves, has assumed a key role in process industries. Hence weigh feeder is a closed loop control system in which a precise control can be had over the flow of materials, which has indicating, totalizing and controlling instruments and circuits. The Weigh Feeder is a custom engineered equipment that finds application in continuous bulk proportioning of solids. This gravimetric feeder is operated by a closed loop control system enabling feeding at a controlled rate and exercises precise control over rate of flow based on a micro controller. The system is capable of accepting external signals from other controllers or from the process computer, depending on the extent of plant instrumentation. These gravimetric feeders are in operation in steel, cement, fertilizer and chemical industries. Each system consists of control and local panels, load cells to measure the instantaneous load, a digital tacho to sense the speed of the belt and a belt feeder conveyor shaft is driven by an AC motor coupled through the gear box.

Hinged Belt

75,000 Per Piece

MS Roller Conveyor

40,900 Per Piece

Idlers Rollers

Get Price Quote

We are offering idlers rollers hi-life idlers - a technological innovation from the house of conveyors aircon idlers are vital parts in any belt conveying system, though it may appear to be of very insignificant. Being subjected to continuous loading & management the same to a great extent decides the overall performance of the system. When the technology was in the stage of infancy, idlers were nothing sort of pipes. By inserting bearings inside these pipes the rotation was made further smooth. Breakdown hours of the equipments corroding the profitability of the industries, there was a need of improvements in design and constructions of idlers. It was in this context aircon hi life idlers were introduced by us a decade ago. This evolution of high tech idlers from aircon has benefited many customers in considerably bringing down their operation maintenance cost of the system. The salient features of this new generation idlers are as below: * detachable with the bearing housing * improved bearing life due to the bearings not being exposed to dust as both the ends are sealed * reduced friction & saving in power * hi life idlers could be repaired by the users instead of being * replaced as in the case of conventional idlers

Twin Screw Feeder

Get Price Quote

Twin Screw Feeding for Powdered Products including Flour, Minerals Chemicals, Milk Powder, Starch and Spices  Weighing Range 5-50Kgs 120-500 Bags/Hour +/-0.05-0.1% of the pack size  State of the art controller with LCD/ Touch Screen display & self-diagnostic features Records – Bag Count, Totalizer, Hours of Operation Easy to configure & troubleshoot Communication – RS232/485, Ethernet, SMS messaging of reports International Standards Certification Â

conveyor idler roller

100,000 Per UNIT

PVC Conveyor Belt

450 Per Piece

drum motor

Get Price Quote

These are designed mainly for conveyor applications. These are totaly enclosed single drive unit with high efficiency and lower friction losses than conventional geared motor. These are as widely used in automation, food processing, packaging machines, weighing systems and many more. Â

drum winches

Get Price Quote

We provide a wide range of 2 Ton Electric Winch, which is manufactured using quality raw material and advanced technology, ensuring high efficiency and longer working life. Our range consists of control panel housed in steel metal enclosure, weather proof, which consists of isolator overload relay contactor giving consistent performance.

90 Degree Turntable

Get Price Quote

5 Unit (MOQ)

timing belt tensioner

1,500 Per Piece

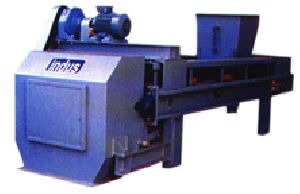

Weigh Feeder

Get Price Quote

Indus manufactures Electronic Gravimetric Weigh Feeders incorporating state-of-the –art technology for continuous bulk proportioning of solids.The material to be proportionally fed is passed over the belt; flow rate (also cumulative value) of the material is measured and compared with set parameters of the PLC/PID controller. The deviation is corrected by regulating the speed of the conveyor through variable speed A.C.Drive. (closed loop control system)Two high precision load cells are used to measure the belt load & a rotary encoder used to measure speed of the conveyor.Salient featuresPrecision machined rollers used to provide perfect belt run & high accuracyRubber coated pulleys prevents belt slippage.Gravity takes up to ensure constant belt tensionScrappers to prevent belt damage & tare changesEasy maintenance - belt change without aids from sideFully automatic Zero/Span calibrationHighly reliable PLC (with in built PID algorithm) & variable speed AC driveHigh precision load cells with damping to obtain best results.Empty Belt Correction Factor to achieve best AccuracySet Points Programmable from local panel or Main PanelOption FeaturesRs 485 Interface can generate printout with SQC AnalysisApplications Cement, Sponge Iron, Steel, Fertilizer, Chemical, Tobacco & Petrochemical Industries.

Magnetic Drum Separators

Get Price Quote

Here a rotating magnetic drum attracts the ferrous chips / dirt from the dirty coolant that falls into it. A scraper is provided ( adjustable scraping angle for chips for less coolant wastage -special feature to be asked ) at a certain angle for the removal of the chips from the drum so that the chips  fall on a chip tray. There are no consumables or change parts. LEX TECHNOAID MAGNETIC DRUM SEPARATORS are made using either RARE EARTH or FERRITE MAGNETS. RARE EARTH MAGNETS ARE VERY POWERFUL & the magnetic drum here is a PLAIN CYLINDER. These are suitable for small chips & the chips that fall in the collection bin are almost free from coolant. Hence coolant wastage is reduced. Rare earth magnetic separators are relatively smaller in size. FERRITE MAGNETIC DRUM SEPARATORS are made with both GROOVED MAGNETIC DRUM & PLAIN MAGNETIC DRUM. GROOVED MAGNETIC DRUM gives higher magnetic surface area to attract coarser chips / particles. PLAIN MAGNETIC DRUM separators with FERRITE MAGNETS are also used for smaller chips LEX TECHNOAID offers MAGNETIC DRUM SEPARATORS for DIFFERENT CAPACITIES OF CHIP & COOLANT FLOWS.

Weigh Feeder

Get Price Quote

Movement of bulk material is an essential feature in modern industrial processes. The simplest and fastest mode of transportation of such material is to convey them over a moving belt. In this operation the precise weighing of material, as it moves, has assumed a key role in process industries. Hence weigh feeder is a closed loop control system in which a precise control can be had over the flow of materials, which has indicating, totalizing and controlling instruments and circuits. The Weigh Feeder is a custom engineered equipment that finds application in continuous bulk proportioning of solids. This gravimetric feeder is operated by a closed loop control system enabling feeding at a controlled rate and exercises precise control over rate of flow based on a micro controller. The system is capable of accepting external signals from other controllers or from the process computer, depending on the extent of plant instrumentation. These gravimetric feeders are in operation in steel, cement, fertilizer and chemical industries. Each system consists of control and local panels, load cells to measure the instantaneous load, a digital tacho to sense the speed of the belt and a belt feeder conveyor shaft is driven by an AC motor coupled through the gear box.