conveyor feeder

Get Price Quote

BMES manufactures all sorts of Screw Conveyor Feeders with excessive precision to go well with the requirement as per CEMA commonplace and this screw conveyor are utilized in much bulk dealing with industries. We’re among the many putative names inside the commerce which are engaged in producing, supplying, buying and selling, and commercialism Screw Conveyor created on the market in quite a few capacities and sizes in order to satisfy the numerous needs of the consumers. This Screw Conveyor is employed by a number of bulk industries to maneuver semi-solid supplies, municipal stable waste, and various issues. Our customers will avail these economical, lengthy lasting, and horizontally inclined machines at commerce main prices.

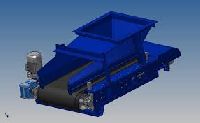

belt feeder

Get Price Quote

Hailing from Karnataka(India), we are engaged in catering to all the customers by reaching their preferred destination. To keep a strict check on the quality of the products, we have hired a team of quality analysts having rich domain experience.

Best Deals from Conveyor Feeder

Twin Screw Feeder

Get Price Quote

Twin Screw Feeding for Powdered Products including Flour, Minerals Chemicals, Milk Powder, Starch and Spices Weighing Range 5-50Kgs 120-500 Bags/Hour +/-0.05-0.1% of the pack size State of the art controller with LCD/ Touch Screen display & self-diagnostic features Records – Bag Count, Totalizer, Hours of Operation Easy to configure & troubleshoot Communication – RS232/485, Ethernet, SMS messaging of reports International Standards Certification

Screw Conveyors & Feeders

Get Price Quote

These units are used for feeding materials to silos, bins and hoppers. Available in both U-trough and tubular trough designs. Close tolerance machining and fabrication in our state-of-the-art manufacturing facility assures equipment quality and performance. Designed especially for various throughputs depending on the system requirements. Manufactured in Mild Steel / Stainless Steel constructions. Special type with variable pitch screw feeders are designed for handling highly free flowing and different bulk densities. Handling capacity varies from 100 kgs/hr. to 100 tons/hr. Type: Horizontal / Inclined / Tubular / U-trough MOC: MS construction / SS304 contact parts Size and length: Suitable for the application Sealing : PTFE / Inmarco Paint: Synthetic enamel paint - 100 DFT. (Optional: Epoxy paint) Starter / VFD: Optional Geared Motor: Chain drive / direct mounted

weigh feeders

Get Price Quote

Loss in-Weigh Feeders operate on the principle of controlled loss-in-weight. The proposed system comprises of a Weigh Hopper, Loadcells, Screw Conveyor with motor and associated control electronics. The Weigh Hopper and Screw Conveyor are mounted on 3 Nos. of Loadcells. The Loadcells are connected to a controller through a junction box. The material from the storage hopper is fed to the weigh hopper, which is controlled by a gate. A small screw feeder is mounted below this weigh hopper. The weigh hopper and screw feeder are mounted on high precision Loadcells and the output of the Loadcells are summed in a junction box and fed as an analog input to the controller. The controller calculates the rate, compares with the set rate and feeds the corresponding 4-20mA signal to the VVVF drive so as to control the speed of the motor of the screw, thereby controlling the rate of discharge.

Weigh Belt Feeder

Get Price Quote

Indus continuous loss in weight feeder provides unparallel versatility in handling wide range of feeding requirements. Feed rate from 50kgs to 1000 kgs per hour can be accomplished with high accuracies. Control of the feeder is through a highly reliable PLC based controller equipped with noise/Vibration elimination technology. Weight measurement is done through highly accurate/sensitive Loadcells. Various models of loss in weight Feeders are available based on the material Characteristics (Flow Properties).a. Twin screw loss in weight feeder.b. Single screw loss in weight feeder.c. Vibratory loss in weight feeder.

Weigh Feeder

Get Price Quote

Movement of bulk material is an essential feature in modern industrial processes. The simplest and fastest mode of transportation of such material is to convey them over a moving belt. In this operation the precise weighing of material, as it moves, has assumed a key role in process industries. Hence weigh feeder is a closed loop control system in which a precise control can be had over the flow of materials, which has indicating, totalizing and controlling instruments and circuits. The Weigh Feeder is a custom engineered equipment that finds application in continuous bulk proportioning of solids. This gravimetric feeder is operated by a closed loop control system enabling feeding at a controlled rate and exercises precise control over rate of flow based on a micro controller. The system is capable of accepting external signals from other controllers or from the process computer, depending on the extent of plant instrumentation. These gravimetric feeders are in operation in steel, cement, fertilizer and chemical industries. Each system consists of control and local panels, load cells to measure the instantaneous load, a digital tacho to sense the speed of the belt and a belt feeder conveyor shaft is driven by an AC motor coupled through the gear box.

Weigh Feeder

Get Price Quote

The weigh feeders are used to proportionally/set value material to feed the manufacturing process. The microprocessor based weigh feeders are used manufacturing plant like steel, cement comical and sand processing plant.

SCREW FEEDER

Get Price Quote

We are offering screw feeder. Aircon provides a wide range of screw conveyors that are suitable for the tasks of elevating, distributing and retrieving a remarkably broad range of bulk material. Requiring minimal floor space, these screw conveyors are ideal for elevating highly abrasive material without causing any damage. features: •high tensile strength •durable performance •high functionality •corrosion and abrasion resistant

Belt Feeders

Get Price Quote

In order to meet distinct requirements concerned with Belt Conveyors, we take pride in introducing you a comprehensive range of Conveyor Belts. These Industrial Belt Conveyors are available in various types depending upon customers’ choices and latest market demand. You can avail them at very affordable rates from our company.

SCREW FEEDER

Get Price Quote

We are offering screw feeder.aircon provides a wide range of screw conveyors that are suitable for the tasks of elevating, distributing and retrieving a remarkably broad range of bulk material. Requiring minimal floor space, these screw conveyors are ideal for elevating highly abrasive material without causing any damage. features: * high tensile strength * durable performance * high functionality * corrosion and abrasion resistant

Screw Feeders

Get Price Quote

High Speed Floating Surface Aerator, Floating Aerator, slow speed mixers

Screw Conveyor Feeder

Get Price Quote

Screw Conveyor Feeder, hammer mill pulverizer, Pin Mill Machine

Screw Feeders

Get Price Quote

GENERAL DESCRIPTION AND SPECIFICATION OF SCREW FEEDER Screw Feeder will consist of a 100 mm to 225mm pitch plate steel helix mounted on a shaft and running in a m.s. fabricated trough. The main components of the feeder will be: Trough which will be fabricated from 3 mm thick m.s. sheets. Both ends of the trough will be closed by 6 mm thick m.s. plate covers which will also have bearing blocks mounted on them. Dust seals will be provided in the end covers. The trough with end covers will be mounted on a fabricated frame. The top cover for the trough will also be fabricated from 3 mm thich m.s. sheet and fastened to the trough by means of bolts. A helicoid flight screw which will be made up of a helix formed from flat steel strip and mounted on a m.s. shaft. The shaft will be partly tubular and partly solid. Solid shaft at both ends will be supported in self sligning ball bearing plummer blocks of C.I. Construction. Drive unit will consist of Geared Motor.

automatic screw feeder

Get Price Quote

automatic screw feeder, automatic optical inspection machine

Weigh Belt Feeders

Get Price Quote

Weigh Belt Feeders, oil batching system, Batch Indicator

Weigh Belt Feeder

Get Price Quote

Weigh Belt Feeder, nylon idlers, HDPE Idlers, On Board Truck Loader Weighing

SS Belt Feeder

Get Price Quote

SS Belt Feeder, Loss In Weight Screw Feeder, Loss-In-Weight Feeder

Aggregate Feeding Belt Conveyor

Get Price Quote

Aggregate Feeding Belt Conveyor

Screw Feeders

Get Price Quote

electrical screw drivers, Screw Driver Bits, torque meter

Weigh Feeder

Get Price Quote

batching systems, Conveyors, Big Bag Filler, Valve Bag Filler

Twin Screw Feeder

Get Price Quote

Twin Screw Feeder, paint filling machines

Twin Screw Feeder

Get Price Quote

Twin Screw Feeder, Slider Bed Conveyors

Weigh Feeder

Get Price Quote

Erection Commissioning Services, Tank Weighing System

Screw Feeders

Get Price Quote

electronics equipment, Solder Pot, electrical screw drivers

volumetric feeders

Get Price Quote

volumetric feeders, Quality Loss in Weight Feeder

SS Volumetric Feeders

Get Price Quote

SS Volumetric Feeders

Coal Feeders

Get Price Quote

Coal Feeders

Gravimetric Coal Feeder

Get Price Quote

Gravimetric Coal Feeder, coal handling equipment

Twin Screw Feeder

Get Price Quote

Twin Screw Feeder, shuttle conveyor, wing pulley, Rack and Pinion Gate