Stone Crusher (gitti)

Get Price Quote

We are suppliers of stone crusher (gitti) in all ovewr bangalore in wholeshale rates.

Hpc Cone Crusher

Get Price Quote

Base on the latest technology and decades of years’ producing experience, SBM designed the HPC series cone crusher. It has excellent crushing efficiency and good hydraulic control system. Now the HPC series cone crusher has wide application in secondary crushing of many kinds of mining and rock, etc. Features Large reduction ratio, high production efficiency; Less consumption of wearing parts, low operating costs; Pyramid broken, perfect of product shape; Hydraulic protection and hydraulic pressure cavity clear high degree of automation to reduce downtime; Application HPC series cone crusher is applied to cement mill, mining, building construction, road &bridge construction, railway construction and metallurgy and some other industries. Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by cone crusher.

Best Deals from Crushing Machine

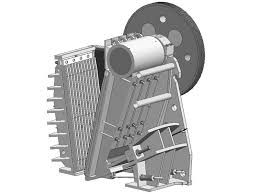

Jaw crusher

Get Price Quote

Reckoned for their corrosion free body, high mechanical strength and easy assembly, our Jaw Crushers are of unmatched standards. Our company is one of the eminent Manufacturers and Suppliers of a wide range of Jaw Crushers. Available with us in varied specifications, the Jaw Crushers are made under expert supervision using the latest technologies. Features of Jaw Crusher : Simple structure. Durable. Low operation costs. Simple maintenance. Long service life. Application :The jaw crusher produce by Wangda Machinery has wide application fields . It is used to crush materials with compressive strength below 250Mpa, and it can break the different sized material into uniform particle sized materials to the next process in the breaking making line.

hand operated sugarcane crusher

18,000 Per Piece

Jaw crusher

Get Price Quote

Creative offers complete range of single toggle jaw crushers for all types of rock, ores & minerals. These crushers are designed to operate in most rugged environment and need less maintenance. Creative Jaw crushers are extremely heavy-duty machines and hence robustly constructed. Creative 's range of single toggle jaw crushers are designed with an upward facing toggle system. This produces a "Flat Elliptical Movement" at the bottom of the swing jaw which increases the efficiency of the crushing. The Unique Elliptical motion of the swing jaw guarantees a highly efficient production rate at every setting. This special motion of the jaw also minimizes scrubbing action common in single toggle jaw crushers.

Stone Crushing Machine

Get Price Quote

Aggregate Jaw Crusher

Get Price Quote

1 Piece (MOQ)

Food Waste Crusher Machine

49,500 Per Piece

Rotating Crusher Machine

Get Price Quote

Shearing steel, Pulverizing, Crushing Concrete. 360° Hydraulic Rotation System. Auto Clearance Control. Reversible & Exchangeable Blade with four edges. Speed up valve can be installed at option.

BB 100 Jaw Crushers

Get Price Quote

The powerful RETSCH Jaw Crushers are designed for the rapid, gentle coarse and primary crushing of hard, brittle and tough materials. The breaking jaws are available in a variety of materials which include heavy-metal-free steel. Their efficiency and safety makes these pulverizers ideal for sample preparation in laboratories and industrial plants. Four basic models are available: from the compact bench-top model BB 50 to the biggest floor model, BB 300 which allows for feed sizes up to 130 mm. RETSCH jaw crushers combine increased operating convenience with maximum working safety.

Automatic Stone Crusher

20,000,000 Per unit

1 unit (MOQ)

HPT Cone Crusher

Get Price Quote

We are offering hpt cone crusher. Features optimized structure for higher production efficiency full hydraulic control for more convenience and reliability integrated hydraulic lubrication system inter-particle crushing for better product quality flexible cavity conversation and wide application

Jaw crusher

175,000 - 375,000 Per piece

1 Piece (MOQ)

HPT Hydraulic Cone Crusher

Get Price Quote

HPT Series highly efficient Hydraulic Cone Crusher is a world-level cone crusher introduced the up-to-the-minute technology of Germany. The cone crusher not only improves the production capacity and crushing efficiency, but also widens applying area, hardness range of materials from limestone to basalt. It has a great crushing performance in the work of medium-size crushing, fine crushing and super fine crushing. The crusher is the improved type of spring cone crusher and can be used to replace ordinary hydraulic cone crusher in the field of mining and construction. It is the most ideal equipment for large stone crushing factory and mining industry. Features HPT Series of highly efficient Hydraulic Cone Crusher has a better performance compared with spring cone crusher and ordinary Hydraulic Cone Crusher:1. High crushing ratio and production efficiency.—— Connection of higher turning speed and stroke makes rated power and passing capacity improved greatly and crushing ratio and capacity increased.2. Less spare part consumption and low operation cost.——advanced crushing principle and technical data, reliable operation and low operation cost. All parts of the crusher have anti-wearing protection, which can make the life time of spare parts increased by 30% and the maintenance cost decreased to the lowest. The crusher avoids the disadvantages of impact crusher like low average crushing ratio, large energy consumption, fast abrasion of blow bar, impact plate and lining board.3. Between-layer pressuring crushing and better finished product shape.——The crusher adopts between-layer pressuring crushing principle and suitable turning speed, not the traditional single particle crushing principle. The special crushing cavity can make the crusher crush materials selectively, thus the proportion of fine product and product of cubic shape is increased distinctly and product of lump size is decreased by a large extent.4. Hydraulic protection and hydraulic cavity clearing, high automatization and less stopping production and repairing time.——Discharge opening is adjusted by hydraulic device and overload protection makes performance of the crusher increased by a large extent, maintenance and operation are easier, repairing time is shorter.; the bidirectional metal releasing hydraulic vat makes slab pass through crushing cavity;the crusher can discharges material automatically when the hydraulic device works under the condition of iron passing and instantaneous overloading, thus there is no trouble of stopping the crusher to discharge material by hand.5. Thin oil lubrication makes the life time increased.——Unique design of thin oil lubrication system prolongs life time of the crusher, high performance and not touchable labyrinth airproof part block off dust and remove common disorders like mixture of oil and water in spring cone crusher.6. Various crushing cavity.——It only need change fixed cone lining board and movable cone lining board; , the type of crushing cavity can be changed from standard coarse cavity to short head fine cavity, which can meet various kinds of requirements.7. Easy maintenance and operation.——all parts of HPT series of cone crusher can be assembled, disassembled and repaired from the top and side part, including the fixed cone and movable cone. If change, no need to disassemble the crusher body and fasten the bolts. Hydraulic motor makes the performance of crusher better.8. The crusher can provide customers larger capacity, better product shape, and easy operation. Working Principle Under the leading role of eccentric sleeve, the movable cone of the HPT Series high-efficiency hydraulic cone crusher does rotary and pendulum movement which drives the broken walls squeeze and twist the raw material between the rolling ace tabular wall and it. According to laminated theory, the raw material is crushed and polished following their own texture by the force from different directions. Stable aggregate are produced finally. The eligible raw material falls down from the gap of the broken wall. The others will be kept crushing until it reaches the desired size. Processed Materials : Iron ore, copper ore, gold ore, manganese ore, river stone, gravel,granite,basalt,mine ore,quartz,diabase,etc. (for hard stone). Applications : Aggregate field,concrete mixing plant,dry mortar plant desulfurization,quartz sand,etc.

Closed Jaw Crusher

1 Per Piece

1 Piece(s) (MOQ)

The Crusher can crush all kinds of minerals, it is widely used in metallurgy mine, chemical industry, building materials, fireproofing materials, ceramics and labs.

Single Toggle Jaw Crusher

2,500 Per Piece

Jaw crusher

Get Price Quote

The jaw crusher produce by Wangda Machinery has wide application fields . It is used to crush materials with compressive strength below 250Mpa, and it can break the different sized material into uniform particle sized materials to the next process in the breaking making line. Features of Jaw Crusher: Simple structure. Durable. Low operation costs. Simple maintenance. Long service life.

Double Toggle Jaw Crusher

Get Price Quote

Leveraging on our technical expertise and competent work force, we are leading manufacturers and suppliers of Double Toggle Jaw Crusher used at primary or secondary stages of crushing. Designed as per quality standards set by the industry, these Double Toggle Jaw Crusher are manufactured using quality raw material procured from reliable vendors. It is appreciated for its high performance, reliability and long life service. Our customers can avail these Double Toggle Jaw Crusher at reasonable prices from us. Benefits of using Double Toggle Jaw Crusher Jaw crusher is used at a primary or secondary stage crushing. It has a large intake to crush large lump size and produce small lumps The material is broken between a stationery jaw and swing jaw. Stationery jaw, as the name suggests, remain fix all the time and the swing jaw acts as a pendulum. The material is crushed between the stationery jaw and swing jaw till it gets reduced to the discharge opening at the end. The hanging swing jaw acts like a pendulum that provides greater shock at the bottom of the jaw. This mechanism overcomes the rubbing problem of stones to the jaw plate and thereby provides longer life to the jaw plate. Double toggle design, even for the smallest size crusher, distributes the load to different spares and protects them against the possible wear. Salient features of using RCI Jaw Crusher: Proven Manufacturing The innovative machine design, the skilled craftsmanship and proven manufacturing are ample reasons for its unique performance thereby delivering the best results to the users. The productivity and functionality of the machine depends largely on the depth and length of the cavity. The proportion of the depth and the length of the cavity is designed in accordance with the intake opening of the machine thereby providing the desired productivity with greater fault resistant functionality Well designed compression springs provide crushing mechanism that eliminates the knocks and resultant water Quality Material & Manufacturing Machine body frame is made of specialized steel plates with adequate thickness and usage of supporting ribs to support the proper functionality with out any breakage. All assembled parts are molded and acted as a single homogeneous entity as compared to fabrication. Parts made from fabrication process uses several joints to form a complete entity thereby comparatively weak to withstand against different wear and breaking conditions as compared to the molded parts. Casted Body blocks are well welded with the machine body frame to create a structure full of strength Jaw plates and side wear plates in the cavity area are made from specialized material- Mn steel, to withstand against possible wear. Shaft, toggle and pitman is made of quality steel alloys providing seamless functionality, with out the fear of fault or breakage. Toggle pin and flywheel is made of alloy of Bronze metal to reduce possible wear and provide longer durability High quality rubber diaphragm provides oil sealing with capacity to withstand against hot oil condition and yet delivering functionality Proven bearings to provide smooth working Flexible design for usage & maintenance Easy mechanism to adjust the discharge opening with adding or removing the setting flats Easy inspection for the oil flow of the machine Adequate swing jaw design that fits different types of jaw plates on it to produce different type of output Safety mechanism Safety mechanism fitted in the flywheel protects the machine by stopping its operation, when a non-crushable material is feeded in to it Oil sensor mechanism to alarm and stop working of the machine in case of lubrication problem of oil on to the eccentric shaft

Jaw crusher

Get Price Quote

Industrial Jaw Crusher is primarily used for crushing of huge lumps of slag. Our Double-Toggle Jaw Crusher is a heavy duty machine that effortlessly crushes large slag lumps into small pieces. The Jaw Crusher that we manufacture is supplied to various other industries where it is used for crushing rock, coal, refractory, stone & glass, etc. Our Jaw Crushers are easy to operate and require negligible maintenance. They are highly efficient and have proved their worth by working smoothly at the client�s end. We have been able to carve out a special place among the prime Jaw Crusher Manufacturers and Suppliers in India.

Mining Crusher

Get Price Quote

Mining crusher machinery is configured to crush very hard material, such as stone, into small rocks, gravel, or stone powder. Mining crusher machines are used to break down raw material, such as mined ore, which are extremely hard to break down.The capacity of a mining crusher ranges from 15th and above,used in Metallurgical industry, Construction.

Cone Crushers

Get Price Quote

We manufacture a series of Cone Crushers for Secondary and Tertiary Crushing applications with a capacity range varying from 80 -350 TPH and can take feed size of up to 220 mm. These Crushers are manufactured as per the latest design features and liner configuration to optimize the crushing results PROMAN introduces the latest technology-based PROcone Secondary and Tertiary cone crushers for crushing all types of feed material to obtain the desired product sizes and capacities in the most economical manner. PROcone provides for: Ease of operation – PROcone has a hydraulic gap setting with push button controls for easy setting of the desired gap to suit your crushing needs. Versatility of operation – Different cavity designs and varied eccentric throws ensure that you receive top-grade quality and quantity of end products. Liner replacement – Made easy by quick dismantling from the top as well. Lubrication – Includes pumps, oil filtration, oil pressure and flow monitoring units, thereby making the system compact. Operating economy – Highly improved as a result of inter particle crushing due to the design and efficiency of the crushing chambers in the PROcone. Liners wear out evenly so that the manganese steel casting is optimally utilized.

vsi crusher

Get Price Quote

Stone Crusher Plant

4,000,000 Per no

Stone Crusher Plant, screen wire mesh, Rock Breaker, Construction Aggregates

Drum Crushers

Get Price Quote

Drum Crushers, FULLY AUTOMATIC CUT TO LENGTH MACHINE

Horizontal Shaft Impact Crusher

Get Price Quote

Horizontal Shaft Impact Crusher, Primary Jaw Crusher, Secondary Jaw Crusher

Wood Crusher

Get Price Quote

Wood Crusher

Stone Crushing Machines

Get Price Quote

Stone Crushing Machines

lime stone crusher

Get Price Quote

lime stone crusher, iron ore, managanese ore, baxuite ore, Bauxite Ore

Mobile Crushing and Screening Plant

Get Price Quote

Mobile Crushing and Screening Plant, grinding mills, linear motion screens

vertical shaft impact crushers

Get Price Quote

vertical shaft impact crushers, Jaw Crushers, Cone Crushers