Rest Blades,Work Blades

Get Price Quote

1 Piece(s) (MOQ)

We are offering special purpose machine components. we are one of the leading manufacturers, suppliers and exporters of special purpose machine components. We provide special purpose machines with the commitment of superior quality to our valuable customers. The configuration of the machines is done as per the requirement of our clients. Our specialty is to deliver special purpose machines in various industrial sectors like hydraulic, moulded, etc. Special purpose machine components has the efficiency to perform, to deliver effortlessly the best quality to their clients.

carbide tipped cutter

200 - 3,000 Per Piece

50 Piece (MOQ)

Best Deals from Cutting Machine Parts

Drill Bits

Get Price Quote

Drill bits are cutting tools used to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shape and can create different kinds of holes in many different materials. In order to create holes drill bits are attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck. Drill bits come in standard sizes, described in the drill bit sizes article. A comprehensive drill bit and tap size chart lists metric and imperial sized drill bits alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section.

Spot Facing Tools

Get Price Quote

We deal in the finest quality Spot Facing Tools in the national market. Our Back Spot Facing Tools are used for back spot facing / chamfering on jobs using drilling machines, Machining centers, Boring machines etc. Their cycle of working can be programmed. Additionally, we are a prime Forward Spot Facing Tool Manufacturer in India. Rear spot facing around the hole is a cumbersome operation while adopting the conventional boring bar with HSS blades or cutters. The time required for fixing, setting and removing the blade/cutter is very high; being HSS, the cutting is very slow; and, whenever the cutting edge becomes blunt, it requires expensive and time � consuming regrinding. All these result in the very high down time of the main machine. The automatic back spot facing tool is specially designed to make the back spot facing operation faster and cheaper. Since it totally eliminates manual interruption during back spot facing operation, not only expensive machine down time is saved, but also it is the most ideally suited tool for back spot facing operation on programmable /CNC machining centers. As the most of tools are offered with standard carbide insert, all the advantages of insert tooling will be available. Construction The back spot facer consists of a case hardened and ground alloy steel shank, which takes location in the hole on which back spot facing is carried out. Provided in the pilot shank is a recess, for accommodating the insert holder or wing. Clamped on the wing is standard carbide insert with the help of a clamp screw. Being LH threaded, it holds the insert in a correct position. In the recess, the wing is eccentrically pivoted on hardened and ground pivot pin and pivot screw. A suitable clearance is provided on the pilot shank to enable it to freely rotate in a drilled hole. These tools are so designed that with various combination of pilot shanks, it is possible to obtain different back spot facing combinations. Sizes and Specification The back spot facing diameter is offered in relationship to its pilot shank diameter � i.e. at ratio 2:1. In other words, back spot facing is possible with this type of tool up to approximately twice the diameter of the nominal diameter of the pilot, subject to some design restrictions. Tools below 12mm pilot are normally offered with solid HSS wing, having integral pivot pin. Operations The automatic back spot facing tool, rotating in reverse direction, is inserted in to the hole. The wing, even it opens in rotation, instantly folds into the recess as it touches the rim of the hole in the work piece. After the wing clearly comes out of the pilot hole, the spindle rotation is reversed to forward direction. Then the wing swing out of the recess due to centrifugal force. With feed it cuts. On completion of the spot facing operation, the spindle rotation is reversed and the tool is withdrawn. During the back spot facing, since cutting force tends the tool to pull down of the spindle, it is adviceable to fix the tool in the machine spindle with a cotter/drive key/draw bolt. It may be noted that the smaller size tools are running at comparatively higher speeds. Here, the wings, therefore, swing out easily due to high centrifugal force. However, large tools operate in lower speeds, which mean centrifugal force acting on the wing may be insufficient, particularly when the tools work in horizontal position, thus resulting the wing to remain in the recess. To overcome this problem, tools above 300mm pilot are provided with spring washer as shown in the sketch. The spring washer keeps the wing open after it comes clear of the pilot hole, irrespective of the speed at which the tool is being rotated.

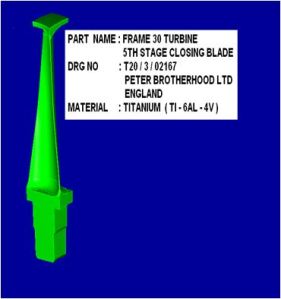

Gas Turbine Blades

Get Price Quote

We are offering gas & steam turbine blades in steel , titanium, nimonic , inconell etc. also blisks and shrouds for turbines. Other precision parts for turbines.

Solid Carbide T-Slot Cutters

Get Price Quote

We are one of the leading Manufacturers and Suppliers of Solid Carbide T-Slot Cutters in Bangalore, Karnataka. Our cutters are manufactured using the latest technology and high-grade metal ensuring the best quality. Our cutters are known for their excellent finish and dimensional accuracy. We can provide Solid Carbide T-Slot Cutters in small as well as bulk quantities to meet the diverse demands of buyers. Our cutters are available at reasonable prices.

Vegetable Cutter

Get Price Quote

Cuts fruits and vegetables, following all safety and sanitation rules. Ensures product meets WFM guidelines for quality and preparation. ... Maintains, or ensures maintenance of, a clean and sanitary working and shopping environment; maintains equipment in accordance with WFM cleanliness and safety standards.

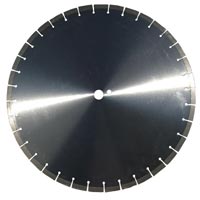

Concrete Saw Cutting Blade

Get Price Quote

The company has cemented its presence among the distinguished Manufacturers, Suppliers and Exporters of Concrete Saw Cutting Blade. The Blades we make available are manufactured using the latest technology. Buyers are free to place bulk orders of these with us and we ensure their timely execution. One can obtain these at reasonable rates from us. Description : Available in the range of 200mm to 1500mm diameter. Features : Free Cutting & Drilling with optimum life Consistent performance Manufacturing : Saw & Segments are produced from latest machineries and technology. Special bond matrix with high-grade diamonds suitable for each type of application.

PVC Copper Foil Cutting Machine

100 Per Piece

Carbide Brazed Cutting Tools

Get Price Quote

Tungsten Carbide Blade

Get Price Quote

High Quality imported tungsten carbide tips are brazed on the saw bodies for optimum cutting & longer life of the TCT saw blades.

Laser Cutting Components

Get Price Quote

We also offer an exclusive range of Laser Cutting Components, which is available in various dimensions and can be personalized as per the requirement of our valued clients.These are fabricated using best grade raw materials in compliance with industry standards.

Carbide Cutting Tools

Get Price Quote

We are one of the oldest channel partners for Mitsubishi Cutting Tools, a $ 1400 million Japanese conglomerate. We specialize in providing tooling solutions to a large customer base in Karnataka, especially in Bangalore, Hosur and Hubli & Dharwad areas. Armed with a dedicated team of sales and application engineers, supported technically by Mitsubishi, we cater to all customers ranging from General Engineering to Aerospace in the field of manufacturing. All our engineers are trained by experts from Mitsubishi, Japan.

Circular Saw Blade

6,651 Per Piece

Parting Tools

Get Price Quote

We manufacture and export an assortment of parting tools bits that are designed with precision. These parting tools bits are offered is various specifications in terms of sizes.

Diamond Abrasives

Get Price Quote

Being a reliable name in this arena, we make sure that the payment procedures remain secured with us. In addition, we issue invoice to the clients stating all the relevant information of the products. Well-established name in the domain, you can count on us for presenting extensive array of Diamond Abrasives.

carbide reamer

Get Price Quote

Our company has set a benchmark in the field of the manufacturing and supplying Carbide Reamers such as Carbide Tipped Reamers, Carbide Tipped Step Reamers, Solid Carbide Step Reamers, Solid Carbide Burnishing Reamers and Carbide Lugged Reamers. The carbide reamers of our company are available at competitive prices and are known for their great finishing. To add on, these reamers are easy to use and corrosion proof.

Cutting Tools - Cutters - CM4SB2

Get Price Quote

Class-leading powerful motor in input and overload durability Metal bush on a ball-bearing and sealed armature coil for durability Easy-to-hold ergonomic handle with soft grip Tool-less depth adjustment

Hss Cutting Tools

Get Price Quote

Cutters have an excellent tool-life and can be used at higher cutting speeds and high feed rates, For slotting or cutting-off where the side faces of the parts should have an clean and an accurate surface.

Single Point Cutting Tool

1,800 Per Piece

carbide brazed tip

Get Price Quote

Block Saws Cutting Tools

Get Price Quote

Process Granite, Marble/Limestone ans Sandstone with Fastcut diamond block saws segments means the following for you: Clearly improved price/performance ratio due to the new sandwich system of the segments fulfills the demands made today on a diamond tool for deep cutting in soft stone. The use of highly efficient bond systems in connection with diamond grain quality guarantees Cost-saving cutting operations and Optimal exploitation of tool and machine performance For cutting of abrasive stone also natural diamond is used because it's particularly suitable for specific operations due to its special grit-shape. Our technicians all over the world are at the customer's disposal for retipping, determination of parameters and the initial operation of block saws. World-wide up-to-date know-how regarding applications gives you decisive advantages particularly for difficult tasks. For the cutting of very abrasive materials both the segment width and the core thickness can be modified as required.

Seco Cutting Tools

Get Price Quote

SECO Tools has an established reputation as a leading manufacturer and supplier of carbide cutting tools and associated equipment. SECO can help to increase productivity, reduce costs, improve the supply chains and use the resources the best way possible SECO provide powerful machining solutions to leading companies around the world. Aerospace, Oil & Gas, Energy and Medical industry solutions are, among many others, where SECO deploys highly specialised machining competence. SECO actively contributes to improving productivity and competitiveness in metal cutting machining. Customer closeness and a solution-oriented approach are strategic cornerstones of SECO, together with verifiable and documented improvements in total cost of production. A comprehensive range of cutting tools is another central component of our strategy and the quality and innovation built into our tools is the key to your profitable production. In order to offer the best total solutions we also provide technical support, demonstrations, technical advice, new ideas and practical experience. We Smart Technologies is the Authorised Distributers for the world wide well known Cutting Tool Product. Customer closeness and a solution-oriented approach are strategic cornerstones of SECO, together with verifiable and documented improvements in total cost of production. We work with the same core values of SECO in providing Technical Solution, Understanding Customer Challenges and Improving the Productivity by reducing the cost of production.

straight round nose tools

Get Price Quote

3 teeth Brushcutter blade

Get Price Quote

Boring Bar

Get Price Quote

Providing Special Boring bars you the best range of Boring Bar such as Boring Bars, Micro Boring Bars, Double Ended Boring Bars and Combination Boring Bars with effective & timely delivery. Our precious clients can avail from us an excellent range of Boring Bars. These products are accurately manufactured at our “state-of-the-art” fabrication unit making use of high grade raw material that is sourced from reliable sources of the industry. Further, we offer these products in assorted specifications according to the needs of the customers. Micro Boring Bars Trin Edge Boring Bars

Pcd Tools

Get Price Quote

We offer pcd tools. Pcd tools & inserts

Counterbore Tools

Get Price Quote

Counter bore tools offer the advantages of throwaway index able carbide inserts. Counter bore tools are offered in any size with single, double or triple cutting edges based on the size. Freely available standard carbide inserts are used. Pilots are detachable types, which permits the use of different dia of pilots for the same dia of counter bore. This feature also enables an easy replacement of damaged worn-out pilots. To facilitate easy chip flow, well-designed gashes and relief are provided on the tool shank.

Boring Bars

Get Price Quote

we offer boring bars. being a professionally managed & a progressive company, we have earned the reputation of being a customer oriented firm by addressing the requirements of our clients. our company with its efficient and dynamic management, is engaged in the custom engineering and designing of products like: collets, collet chucks, tool holders, boring bars, indexable boring bars, customized boring bars.

Dovetail Cutters

Get Price Quote

Regular face milling and shoulder milling cutters cannot be used to create acute corners in components such as guide rails of machine beds. Dove-tail Cutters, are designed to suit the angle which it must achieve. These cutters can also be used as face mills if required, during the same process of dove-tail machining.