TriboChemist

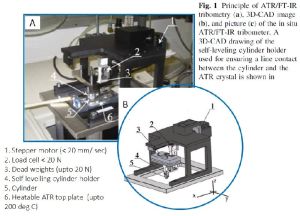

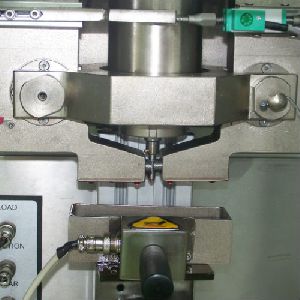

Lubrication science has greatly improved energy efficiency, health and personal care. Lubricants are mainly categorized by their ability to prevent wear and reduce friction in a variety of test conditions. Manufacturers of lubricants use increasingly complex additives to lubricants to optimize performance. However, in order to effectively tailor lubricants to specific applications and produce “designer” lubricants, one must understand the fundamentals of how molecules in a lubricant interact with surfaces and more importantly, change when subjected to mechanical shear. It is important to understand these parameters and how they influence friction. In many cases, the change in molecules when subjected to tribological tests are reversible and therefore undetected by traditional test methods. With the use of an innovative tool like the Ducom TriboChemist, researchers can now access in-situ data from a test to characterize chemical and tribological behavior of a lubricant. The Ducom TriboChemist combines an Infrared Spectrometer with Attenuated Total Reflection (ATR) crystal and a specially developed Linear Reciprocating Tribometer (LRT). This integrated system includes a friction sensing module for acquiring the tribological component of tests conducted on the TriboChemist. The system can house a cylinder, pin or a ball as the moving (upper) specimen which is pressed against an ATR crystal surface to produce a point, line or an area contact. Users can program the TriboChemist to customize tests by configuring stroke length (displacement), sliding speed, test load (contact pressure), and duration of test. Temperature and humidity control are also possible. Features State of the art in-stiu tribometer Includes integrated FTIR spectrometer with high signal to noise ratio Computer controlled operation with software license included. Capable of standard linear reciprocating tests as well as user configured stroke type and speed. Speed settings include: fixed speed forward and reverse, custom forward speed, custom reverse speed. Stroke type setting include: continuous and intermittent stroke length. Test script for acquiring IR spectra – before, during and after friction test. ATR crystal Surface – Ge/Si/Diamond, Ge with FeO coating, Ge/Si with polymer coatings. Options Humidity Controller Flow Chamber with Heating Jacket for ATR (ambient to 200 Deg C)

...more

Timken OK Load Tester

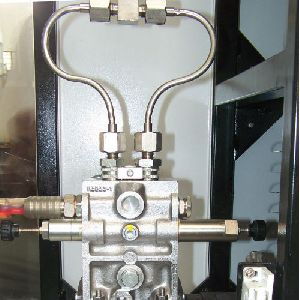

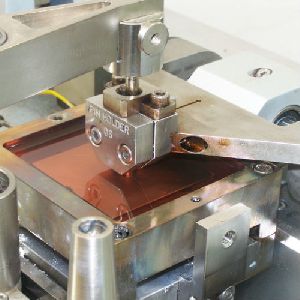

The Timken O.K. Load Tester is a lubricant oil/grease testing instrument based on the machine produced by the Timken Company from 1935 to 1972, which originally was used to evaluate the load carrying capacity of lubricants. It is a quick and reliable test that can evaluate fundamental properties involved the research, development, and quality of lubricants. This instrument is especially useful for Research & Development and Quality Assurance activities. Samples are easily available and can be set up quickly, making it a good choice for lubricant and EP additive evaluation and qualification, O.K. Load quantification, EP protection, Wear Prevention (WP), and frictional characteristics. The O.K. Load Tester uses a steel bearing race which is pressed against a steel test block creating a line contact which is representative of many tribological contacts en- countered in real life applications. The bearing race is attached to a spindle which rotates the race while the test block is pressed against it. A reservoir for lubricant oil rests below the bearing race. If using grease, there is a system that feeds the grease into the contact area. The test load is then increased until the film between the bearing race and the block is broken. The maximum load before scoring occurs is reported as the “O.K. Load”. The minimum load applied required to cause scoring is reported as the “Score Load”. The O.K. Load is essentially used to measure the ability of a lubricant to protect under EP as well as boundary lubrication conditions. Features Optical microscope included for scar measurements. Computer controlled operation with software license included. Availability of a variety of options. Options Automated Loading Arrangement Automated Grease Feeder High Temperature Fluid Bath (ambient to 200 Deg C) Digital Image Acquisition System (in lieu of optical microscope)

...more

Slurry Pot Erosion Tester

A rectangular sample under evaluation is made to rotate in a slurry cup. The sample is weighed before and after the test to determine loss of mass due to slurry erosion. Volume loss is computed for comparison, due to difference in densities of materials. Index of erosion is reported as loss of volume. The test rig permits running up to 6 test samples at the same time and same speed. Slurry cups are immersed in water bath to maintain slurry temperature. Test duration can be preset with timer. Features Preset revolution count / duration of test. Heating/cooling fluid circulation jacket. Up to six different samples tested together.

...more

Slurry Jet Erosion Tester

Erosion leads to loss of life of components in machinery and pipeline which handle slurry. In order to maximize life, proper selection of materials used is required. Slurry Jet Erosion Tester facilitates identification of best material under given operating conditions. Rate of wear determined experimentally can be used to predict service life and life cycle cost. A water jet with erodent impinges upon sample under test. Test variables are: Velocity Angle of impingement Erodent type and size Slurry concentration Duration Loss of weight of the sample after test is determined. It is converted to volume loss for comparative ranking of various materials. Features Wide range of test variables Closed loop re-circulation for water conservation Test components directly with customized adapter

...more

slurry abrasion tester

The Slurry Abrasion Tester is designed such that a flat test sample is pressed radially against a wheel with a known force. The test area is submerged in wet abrasive media (slurry). The arrangement is such that the wheel carries the abrasive media between the sample and the wheel creating a scenario of three body wear using the slurry in the chamber. This tester allows users to test under a variety of loads, flow rates and types of abrasive media. Loss of weight of test samples indicates wear resistance. Features Auto shut off on test completion. Easy test setup and clean operation. Corrosion resistant materials for long lasting performance.

...more

Shear Stability Tester

Lubricants are often subjected to mechanical shearing, for example in automotive engines. This shearing causes lubricants to lose their viscosity. When subjected to sufficiently large number of cycles of shear, viscosity may drop below acceptable levels and may call of replacement failing which surfaces may become prone to higher wear. Even lubricants that have consistent viscosity through a wide temperature range (high viscosity index) may still be susceptible to loss of viscosity when subjected the mechanical shearing. Shear Stability Tester is an instrument used to determine an oils ability to retain its viscosity over a number of cycles of shear. The test oil is first measured for its initial viscosity after which it is subjected to shearing in intervals of 30 cycles. Viscosity is measured and compared to the oils initial viscosity following 30, 90 and 120 cycles. Oils that show a lower drop in viscosity over the duration of test are said to have better shear stability than oils that exhibit a relatively higher drop in viscosity. Features Floor standing designIncluded safety enclosure Options Recirculating chiller (if no water line is available)

...more

Scratch Tester

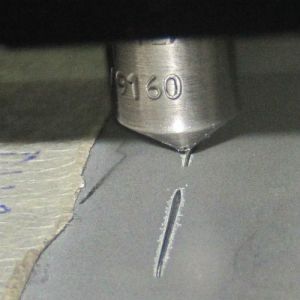

There is a growing trend towards the use of modified surfaces for improved performance and life of components. Modifications are invariably in the form of coatings on base material. They are deposited by electroplating, vapor phase deposition, diffusion, thermal spray or welding. Coatings need to be characterized for parameters like scratch resistance, critical load, adhesion and nature of damage under high stress. The Scratch Tester by Ducom facilitates these measurements over a wide range of parameters. Applications Critical load of hard and brittle coatings like titanium nitride, ceramics Determination of working load limit of soft coatings like PTFE and other polymers. Identification of process parameters of heat treatment for best scratch resistance Estimation of bond strength at substrate – coating interface Product development and quality control of surface engineered products Features Compact design. Open platform for ease of use and access when setting up samples. Computer controlled operation with software license included. User friendly software interface with CompariView module for comparative viewing of test results. Variety of options and accessories to extend testing capabilities. Options Low Load Head – up to 2 N High Load Head – up to 20 N Depth Sensing Module Acoustic Emission Sensing Module High Temperature Stage – ambient to 150 Deg C Advanced Motion Control Module Integrated Image Acquisition System Integrated 3D Non Contact Profilometer

...more

Rotating Beam Fatigue Tester

The purpose is to carry out rotating bar bending fatigue tests without deliberately introducing stress concentration in accordance with DIN 50113. A test piece mounted as a cantilever with single point loading is made to rotate and thus subjected to a bending moment. The force giving rise to the bending moment do not rotate. Features Auto shutoff on test completion. Rugged floor standing design.

...more

Rotary Tribometer

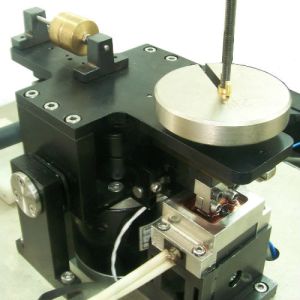

The Ducom Pin/Ball on Disk Tribometer is a test instrument designed for accurate and repeatable tribological characterization of bulk materials, coatings and lubricants. Easily changeable holders allow users to quickly change the nature of tribological contact to something that is relevant to their application. A wide range of factory installed and field upgradable options make this system very scalable, ensuring years of unhindered research for various types of applications. The Pin/Ball on Disk Tribometer by Ducom is used by hundreds of labs worldwide for all their material bench-marking and materials development needs. In addition to standard configurations, Ducom also offers custom developed Pin/Ball on Disk Tribometers that are designed to meet highly specialized testing needs ranging from tests in exotic environments like pressurized helium or molten sodium to very high or low temperatures, loads and speeds. Features Compact Design. Friction and Compound Wear Sensing Module offered as standard supply. Large number of options for extended testing capabilities. Computer controlled operation with software license included. Options Automated Loading System Environment Chamber Lubricant Cup Lubrication Module Electrical Contact Resistance (ECR) Automated Radial Positioning Module Angular Oscillation Module Elevated Temperature Modules (various ranges) Vacuum Chamber

...more

Roller Element Bearing Tester

Roller element bearings are anti-friction bearings used to reduce wear and friction in high axial and radial load applications. The life of an individual rolling bearing is defined as the number of revolutions bearing endures before the first sign of fatigue (flaking, spalling) occurs on one of its rings or rolling elements. Purpose of this test rig is to determine life by varying the speed, axial load, radial load and lubricating conditions. Four identical bearings are mounted on a shaft. Axial and radial loads are applied when bearings are running. Failure of a bearing is sensed by abnormal increase of either vibration or temperature. At this point, the rig stops. Number of revolutions to fail is recorded. This data is used in Weibull failure analysis to determine fatigue life L10. This is the life which 90% of the bearings in a sufficiently large group can be expected to attain or exceed. Features Testing of 4 bearing samples at a time Variety of lubrication system – bearings packed with grease, bearings partially submerged in oil sump, bearings with recirculating oil jet Axial, radial and simultaneous application of axial and radial loading. Controlled loading profiles – Step, ramp, linear and constant loading Control system ensures load is maintained at the preset value with no overshoot Pre-programming of test schedule User defined trip limits based on vibration amplitude and temperature Options Radial Loading Modules Axial Loading Modules Bearing Temperature Measurement Lubricant Temperature Measurement Lubricant Sump Temperature Control and Measurement (Ambient to 120 Deg C) 3 Axis Bearing Vibration Measurement Module RealData® Module (Road Load Data (RLD) / Field Data Replicator)

...more

Reichert Tester

The Reichert tester is an excellent tool for lubricant and additive manufacturers to evaluate the wear preventive (WP) and extreme pressure (EP) properties of their samples. This test was developed as a quick method to identify the formation of a lubricating film between two test surfaces. The Reichert Tester uses a drop in noise level (screeching) to identify when a lubricating film is successfully formed between the test surfaces. Traditionally, this tester was shut off when a perceivable reduction in noise was observed. This required trained and an experienced operators to run tests with accuracy. As a result of this operator dependency there was often a variance in the observed test results. This problem was addressed by Ducom by incorporating instrumentation to monitor and log noise level, therefore reducing operator dependency. The Reichert Tester sees significant utilization by lubricant and additive manufacturers to evaluate and rank their products quickly in their development / product formulation phase. It is also very useful for additive depletion studies and lubricant selection for metallurgy. This tester also sees use as an effective tool to determine lubricant quality while in use in machinery. Its requirement for a small sample volume allows maintenance staff to withdraw small lubricant samples from machinery and run a quick test to determine if it is time to replace the lubricant. This tester is capable of testing both, lubricating oils and greases. Features Integrated “Noise Detection Module” with software. Auto-Shutoff when set noise threshold is exceeded. Optical microscope included for scar measurements. Computer controlled operation with software license included. Availability of a variety of options. Options Wear measurement gauge. Friction measurement module. High temperature fluid bath (ambient to 200 Deg C).

...more

Pour Point Tester

Ducom’s DPP offers precise, fully-automated pour point testing of crude oils, engine oils, additives, lubricating oils and other petroleum products. The DPP features an automated, mechanical arm that lifts and tilts the test jar with incredible accuracy. It is also equipped with Ducom’s innovative software system, which can manage up to six analytical heads with ease and delivers customizable reports and graphs at the touch of a button. Key Features: Integrated Touchscreen Panel PC: 12-inch, TFT/LCD, high-resolution display Automated Operation: Delivers precise, consistent results, decreasing the risk for human error User-Friendly Software Interface: Customize analysis parameters and methods Storage Capacity: Record, save and store data files in an Excel-compatible format

...more

Pin on Vee Block Tester

The Pin and Vee Block Tester can be used to test a variety of test materials for their tribological properties. It is used for testing both dry lubricants as well as fluids like lubricating oils and metalworking fluids. It is also useful for testing materials and coatings that need to be tester for their wear and friction performance. The system measures frictional torque and , and the maximum pressure it will withstand before the lubricating properties fail. This work can be performed at various temperatures. It operates by having a small, rotating, cylindrical pin squeezed between two metal arms with vee-notched blocks attached. The testing can be performed immersed in oil which is being heated to a desired temperature. It is also suitable for testing dry film bonded lubricants and additive packages. This test instrument consists of rotating pin (journal) pressed between two stationary steel V-blocks. Load is applied to the V blocks by a ratchet mechanism. Ramping of load during extreme pressure testing is made possible by auto advancement mechanism of rachet. When testing tribological properties in fluid lubricants, the “Pin and Vee” blocks are immersed in lubricant fluid under test in a heated test cup. Wear is determined as the number of teeth of the ratchet mechanism advanced to maintain load constant during the prescribed testing time. Torque – load diagram shows extreme pressure behavior of lubricants. Load at which the shear pin breaks or inability of ratchet mechanism to take up load automatically is defined as failure load. Endurance (wear) life test of the film lubrication is measured by the length of time taken for torque to increased by specified value. Features Computer controlled operation with software license included. Availability of a variety of options. Options Advanced (pneumatic) loading system

...more

Pensky-Martens Flash Point Tester

The FPM provides accurate and secure flash point testing for users seeking to characterize the volatility and flammability of biodiesel fuels, lubricating oils and petroleum products. Key Features: Integrated Touchscreen Panel PC: 8.4-inch, TFT/LCD, high-resolution display Storage Capacity: save and store data files in an Excel-compatible format User-Friendly Software Interface: automated, temperature-controlled testing Advanced Safety Features: automated diagnostics, fire detection system and overheating protection

...more

Noack Evaporation Loss Tester

Oil evaporation loss, especially as it pertains to engine lubricants, can have an adverse effect on the quality and lubricating performance of certain motor oils. The Noack test is used to determine the evaporation loss of lubricating oils at high temperatures. Test results will help to quantify and assess the potential performance and sustainability of motor oils under extreme temperature conditions. The NEA is an advanced, state of the art evaporation loss tester. It features a newly-designed aluminum block and a powerful vacuum pump, for improved performance and durability. Key Features: Integrated Touchscreen Panel PC: 8-inch, TFT/LCD, high-resolution display Automated Calibration: Display, record and print calibration history of each temperature probe Innovative Software Capabilities: Customize parameters, print graphs and results Storage Capacity: Save and store over 60,000 data files in an Excel-compatible format

...more

MicroForce Tribometer

The Ducom MicroForce is an innovative new platform can be used for multi-scale testing. The patented MicroForce head is used to control test load with high accuracy and measure friction force between between the range of 10 mN to 10 N. The MicroForce, with its sub-micron resolution, is excellent for micro-scale friction measurement. This tool can be used for a variety of innovative tests including mapping the independent effects of surface force and deformation on interface friction. Overall, the MicroForce platform is an essential tool for any lab that has an interest in multi-scale testing ad evaluating the effect of scale in tribology. The Ducom MicroForce head can also easily be integrated into various versions of the the Ducom Rotary Tribometers, Linear Reciprocating Tribometers and Scratch Testers. Features Interchangeable springs for a wide range and high resolution measurements of normal load and friction force. Interchangeable drives for linear reciprocation, rotation and oscillatory motions. Acquisition of force vs. displacement curve to determine the adhesion force and energy. Temperature Control System for operating at a temperature range between room temperature to 80 Deg C. Humidity Control System for operating at a humidity range between 30% RH to 75% RH. Tribocorrosion Cell with a three electrode potentiostat to generate linear polarization curves according to ASTM G59 and determine the mass loss due to corrosion. Options Interchangeable Drives: High precision stages for linear movements and low speed rotation. Lubricant Cup and Heating System: Lubricant cup to accommodate specimen disc and test lubricants. The temperature of the lubricant is controlled using cartridge heaters and PT-100 sensors. Humidity Control System: The stand alone humidity controller can generate dry and humid air to augment the capabilities of your tester to evaluate humidity dependent properties of materials. TriboCorrosion Cell: The tribocorrosion cell when used with a three electrode potentiostat can facilitate the determination of the open circuit potential, linear polarization curves, Tafel plot and corrosion mass loss.

Operating Temperature : Ambient Temperature to 80 Deg C

...more

Low Temperature Torque Tester

The Low temperature torque tester is designed to determine starting (break away) torque and running of greases at sub zero temperatures. The test system is used to evaluate the tendency of various greases to offer resistance to the rotation of bearing at low temperatures (sub zero). Low temperature torque tests are of prime importance for aviation applications where equipment is required to perform without glitches in sub zero environments. The test system consists of a test area where a bearing, with the grease under test is setup. When the test samples attain the desired temperature, the test commences. The Ducom Low Temperature Torque Tester comes with the WinDucom software for data acquisition and display of results. This system can record torque. WinDucom software is used to present data in a variety of ways and CompariView provides a powerful tool to view and compare test results for evaluation. Features User friendly software interface. Computer controlled operation with software license included.

...more

Linear Reciprocating Tribometer

Materials, coatings and lubricants often encounter situations involving repeated back and forth (reciprocating) movements during operation. Such situations are seen in various applications ranging from automotive to bio-materials for implants. These contacts may see a range of operating conditions from low amplitude, high frequency reciprocation to high amplitude and low frequencies. The Ducom Linear Reciprocating Tribometer is designed to allow users to characterize tribological performances of materials and lubricants in a wide range of operating conditions ranging from fretting wear conditions to large amplitude linear sliding conditions. If can effectively be used to study bulk materials, coatings, lubricants and additives. The Linear Reciprocating Tribometer can accommodate a variety of sample geometries to create point, line and area contacts. Customized sample holders can also be provided for tests requiring conformal contacts. This system is computer controlled and includes a data acquisition software that can be used to acquire, view and report results. Features Patented open platform design for easy sample access.Compact layout with highly customizable testing capabilities.Variable stroke length with unparalleled stroke and frequency range.Patented design allows easy sample examination without removal of samples from holders.Large number of options for extended testing capabilities.Computer controlled operation with software license included. Options Lubrication Cup (for submerged, lubricated tests). Environmental Chamber (for controlled environment tests). Tribo-Corrosion Module Advanced Motion Control Module (for advanced stroke programming) Automated Loading Module High temperature modules. (Various temperature configurations up to 1,000 Deg C) Electrical Contact Resistance (ECR) measurement.

...more

Journal Bearing Tester

The Ducom Journal Bearing Tester (Basic) is designed to demonstrate and study pressure distribution behavior of lubricants in journal bearings. The system consists of a vertically mounted journal driven by a variable speed motor. The load is applied radially to the bearing with a loaded lever. Journal bearing assembly is immersed in lubricant. An electronic sensor measures the oil film pressure. The angular position of the pressure senor with respect to the load line is varied and pressure is recorded. Pressure is plotted as a function of angular position of Cartesian or polar form to demonstrate the pressure distribution. Test variables are journal speed, radial load and lubricant viscosity. Features Compact Design. Measurement of pressure profile. Computer controlled operation with software license included.

...more

Humidity Controller

Tribological properties of materials can greatly be influenced by humidity. Coatings like Diamond like Carbon (DLC) see great use in a variety of applications ranging from hard drives and automotive engines to biomedical applications. Each of these applications presents very different operating conditions which includes humidity conditions. DLC is also known to have friction properties that vary greatly with humidity. It is therefore extremely important to characterize materials for their tribological properties by including their performance dependency on parameters like humidity. The Ducom Humidity Generator is a stand-alone system that can easily be plugged into any compatible Ducom Tribometer. This extends the capability of your existing or new tribometer to include the ability to carry out tests and understand material behavior under a variety of humidity conditions. The Ducom Humidity Controller is capable of producing an output of dry or humid air to control conditions within the test area. A combination of dry and humid air is used to create an environment of the required RH. The Humidity Controller comes with a humidity sensor that is placed within the test area and requires oil free and dust free pneumatic input. The system is self-contained with respect to drying and humidification systems and requires very little maintenance. For proper operation, the tribometer is required to have a Humidity Controller compatible enclosure. Features Standalone unit Portable, accurate and reliable Easy to handle and maintain Versatile – can be used with a variety of Ducom tribometers and also other compatible systems. Applications Characterization of coatings like DLC. Improved accuracy for standard tests by controlling humidity. Evaluating frictional properties of materials sensitive to humidity.

...more

High Temperature Grease Tester

The Ducom High Temperature Grease Tester is an excellent tool to determine the life of lubricating greases designed for operation at elevated temperatures. The grease under test is filled in a bearing as specified by the ASTM D3336 and mounted on a spindle. The bearing is located in the elevated temperature chamber that is used to heat the test grease to the desired temperature and maintain the temperature during the test. The test applies relatively light load and runs the bearing at high speeds. This determines the ability of a grease to provide lubrication to the arrangement at elevated temperatures over extended periods of time. The signals from sensors are processed and transmitted to a computer. Here, test information is recorded and presented for analysis. The user-friendly software WinDucom for control and acquisition works on any Windows based PC. The software has three distinct sections, one for programming and setting up tests, second for acquiring and displaying real-time test data and the third is the CompariView mode, used to compare results of up to four tests. Features Computer controlled operation with software license included.Capability to attach multiple systems to a single software interface. (Optional)

...more

High Frequency Reciprocating Test Rig

The purpose of this tester is to characterize friction under lubricated condition using a ball on disc configuration. This tester is particularly suited for evaluating low lubricity fluids like diesel and gasoline. The system consists of a temperature controlled stage that houses the test plate. A reciprocating arm with a ball holder to hold the test ball is pressed against the test plate with a known force. The system reciprocates maintaining the required stroke length, frequency, load, temperature and humidity. A piezoelectric force transducer senses the frictional force. The unit is computer controlled and uses the WinDucom Data Acquisition System to record the output parameters. Features Compact bench-top design. Includes environment chamber and humidity probe. Includes ambient temperature and relative humidity probe. Especially suited for wear tests of diesel fuels, additives and lubricants. Pre-programmed CEC, ASTM and ISO test procedures for automated operation. Computer controlled operation with software license included. Includes CompariView module for comparative viewing of test results. Options Humidity ControllerElectrical Contact Resistance (ECR) ModuleTribo-Corrosion CellHigh Temperature Module (Ambient to 400 Deg C)

...more

Gas Jet Erosion Tester

Erosive wear is caused by the impact of particles air jet impinging on a solid surface. Erosion leads to loss of life of components in aerospace, gas turbines, boilers and power plants. In order to maximize life, proper selection of materials used in such applications is required. The Ducom Gas Jet Erosion Tester facilitates determination of wear rate under wide range of conditions. Wear rate can be used to identify the best material under given operating conditions. It can also be used to predict service life and life cycle costs. Erosive wear is caused by the impact of particles air jet impinging on a solid surface. Erosion leads to loss of life of components in aerospace, gas turbines, boilers and power plants. In order to maximize life, proper selection of materials used in such applications is required. The Ducom Gas Jet Erosion Tester facilitates determination of wear rate under wide range of conditions. Wear rate can be used to identify the best material under given operating conditions. It can also be used to predict service life and life cycle costs. Features Erodent flux rate control High temperature test options Double disc velocity meter Easy changing of samples Easy replacement of nozzles Easy machine operation ASTM G76 compliant Options High Temperature Module (ambient to 600, 800 and 1,000 Deg C) Motorized sample stage for impingement angle setting.

...more

four ball tester

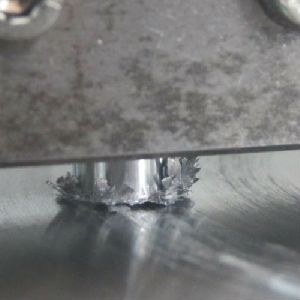

The Four Ball Tester is an excellent development and quality check instrument for developers and users of lubricants and additives. The unique sample configuration of three bottom balls and one top ball makes a very stable and a repeatable contact in-turn, allowing tests results to be very repeatable. The Four Ball Tester can be used to determine Wear Preventive properties (WP), Extreme Pressure properties (EP) and friction behavior of lubricants. The wide acceptance of test results of the Four Ball Tester make it an excellent choice to benchmark products. It is a good choice for R&D due to its relatively inexpensive samples and ability to produce quick and repeatable results. A rotating steel ball is pressed against three steel balls firmly held together and immersed in lubricant under test. The test load, duration, temperature and rotational speed are set in accordance with standard test schedule. In Wear Preventive (WP) tests – also called Anti Wear (AW) tests – the average scar diameter on the bottom three balls is reported. The size of the scar shows the ability of the lubricant to prevent wear. A larger diameter indicates poor wear preventive property while a smaller indicates superior wear preventive property. In Extreme Pressure (EP) tests the lubricant is subjected to load that is increased in specified steps after every run. This increase in loading is continued till a load is reached where the lubricant fails. The failure of lubricant is indicated by welding of the bottom three balls to the top ball. The load at which welding occurs is the index of extreme pressure property of the lubricant. Features Single instrument for Extreme Pressure (EP) and Wear Preventive (WP) tests. Built-in “Collet Master” attachment for sample loading. Optical microscope included for scar measurements. Computer controlled operation with software license included. Availability of a variety of options. Options Automated Loading Arrangement KRL Shear Stability Attachment Rolling Fatigue (IP 300) Attachment Ball on Three Disks Attachment High Temperature Ball Pot (ambient to 200 Deg C) Digital Image Acquisition System (in lieu of optical microscope)

...moreBe first to Rate

Rate ThisOpening Hours