dust extraction unit

Get Price Quote

Provided with stainless steel S.S 304 contact parts Blower fan is dynamically balanced Machine in fitted with the castor wheels for easy mobility Overcome dust hazards as well as cross contamination at tablet compression All inlet manifolds and dust collection trays are of SS 304 Four inlet manifolds facilitate to connect any Tablet press machine and two for De-burring units

Dust Extraction System

Get Price Quote

We manufacture dust collectors for all types of applications related to dust. Good quality

Best Deals from Dust Extraction System

Dust Extraction System

Get Price Quote

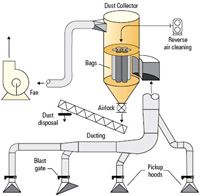

Recovery of particulate matter from exhaust gas is vital for any industry from three aspect Dust Extraction Diagram To ensure the operators health and safety by removing the hazardous fumes from the working area To avoid pollution problems Sturdy construction To increase the product quality removing fumes from the process Dust collection systems is used in many processes to either recover valuable granular solid or powder from process streams, or to remove granular solid pollutants from exhaust gases prior to venting to the atmosphere. Dust collection is an online process for collecting any process-generated dust from the source point on a continuous basis. Dust collectors may be of single unit construction, or a collection of devices used to separate particulate matter from the process air. They are often used as an air pollution control device to maintain or improve air quality. The dust generation in manufacturing process directly effects the operator�s health, can contaminate the product which is being manufacturing can make highly uncomfortable for the people in & around the dust generating areas. BATS wish to offer a solution by incorporating dust control & extraction system & ensure a safe & pure zone for the occupants. This process involves exhaust blowers, exhaust air duct work and dust collection hoods to pick up dust particles at the point of generation. In several cases, the dust collected by the system from the point of generation is routed through a filter unit which collects the dust & pure air will be exhausted to the ambient to meet pollution control.

Dust Extraction System

Get Price Quote

The casing of Rotary Polygon Screen will be fabricated from 3 mm thick m.s. sheets suitably reinforced with rolled steel sections. The bottom part of the casing will be rectangular in the shape while the top part will be pentagonal or hexagonal in shape and bolted to the bottom part. Removable panels/doors will be provided in the top part of the casing for inspection purpose. A feeding/receiving chute will be provided at one end of the top part to receive sand from conveyor, elevator or similar feeding device. Provision will be made in the top part of the casing in the form of circular opening for connection to dust extraction system. The main driving shaft of mild steel will be carried at each end in externally lubricated self aligning ball bearing blocks. Keyed to the shaft will be m.s. or cast iron hexagonal hubs fixed to which will be m.s. radial arms on which will be bolted the frame carrying replaceable wire mesh screen. Product ranges from capacity of 10 tons/hr to 80tons/hr. For removal of large pieces of scrap and hard lumps of sand etc. which cannot pass through the wire mesh screen and which travel right through to the end of the screen, suitable reject opening will be provided. Drive will consist of motor with gearbox . Necessary sheet metal steel guards will be provided over the coupling.

Dust Extraction System

Get Price Quote

We have attained a remarkable position in market by offering flawless range of dust extraction system. For removal of dust from air, a filter is ideal. We provide high quality product which is made up of premium quality raw materials. Our product is highly powerful and can easily extract all the dust from the system. These dust extraction systems are widely used for extraction and collection of dust particles with different nature and specifications.We design, manufacture, install & commission dust extraction system as required for the layout of the plant for dust and fumes. Our experienced team of design and installation of engineers will work with you to provide a system to suit your requirements and budget. The quality of our team ensures that this dust extraction system is stringently monitored on various parameters. It is extensively appreciated for its high strength, optimum performance, corrosion resistance and longer functional life. The offered system is available in various customised options as per the needs of the clients. We aim to give timely service to our client at affordable rate.

Dust Extraction Systems

Get Price Quote

We understand that the use of finest grade raw material brings forth high quality product line. In addition to this, we make sure that the material is sourced from the reliable places only. To pay for an order, we can agree upon a payment method as per you and our convenience. We are okay with online as well as offline payment options and wish to make payment easy.

Dust Extraction System

Get Price Quote

Dust Extraction System, Bag filling Machines, Pressure Vessels

industrial dust extraction system

Get Price Quote

industrial dust extraction system, air cleaning filter, Heat Exchanger

Dust Extraction System

Get Price Quote

Dust Extraction System, Cement Silo, Baling Machine

Dust Extraction Systems

Get Price Quote

Dust Extraction Systems, Belt Conveyors, Stop Log Gate, Storage Tanks