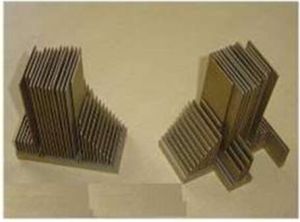

Extrusion Heat Sinks

Get Price Quote

A heat sink is designed to maximize its surface area in contact with the cooling medium surrounding it, such as air. Air velocity, choice of material, protrusion design and surface treatment are factors that affect the performance of a heat sink. Heat sink attachment methods and thermal interface materials also affect the die temperature of the integrated circuit. thermal adhesive or thermal grease improve the heat sink's performance by filling air gaps between the heat sink and the heat spreader on the device. A heat sink is usually made out of copper or aluminium. Copper is used because it has many desirable properties for thermally efficient and durable heat exchangers. First and foremost, copper is an excellent conductor of heat. This means that copper's high thermal conductivity allows heat to pass through it quickly. Aluminium heat sinks are used as a low-cost, lightweight alternative to copper heat sinks, and have a lower thermal conductivity than copper. We manufacture both in the highest qualities.

Extrusion Heat Sink

Get Price Quote

Best Deals from Extrusion Heat Sinks

aluminium extrusion heatsink

Get Price Quote

aluminium extrusion heatsink

Heat Sink Extrusion

Get Price Quote

Heat Sink Extrusion, Press Component Job Work, led heat sink