Ozone Water Treatment Plants

Get Price Quote

Ozone (O3) is a very effective disinfection agent and can be used to replace chlorine and bromine containing disinfection chemicals. The advantage of the use of ozone compared to the other treatment agents is the fact that the treatment effectiveness will increase dramatically and the use of ozone prevents the formation of harmful by products. We are Premier Ozone Wastewater Treatment service providers in Bangalore, Mangalore & Mysore.

Linear Vibrating Filling machine for gherkin in Glass jar and Tin Can.

550,000 Per piece

1 Piece (MOQ)

VIBENG designed Linear Vibrating Filling machine to feed Gherkin in linear direction to glass jar or metal tin can in the Gherkin processing packing line. It also suaitable for other vegetable line like Baby corn, Olives, Mushrooms, Whole Gherkins and Hamburger drill chips etc. Vibeng's Design features:1. Fabricated corrugated profile sheet trough.2. Rotatable Discharge chute to accommodate the jar and tin can different height .3. Easy to clean.4. Less maintenance and minimum downtime.5. Drive system mounted at back.6. M.O.C-SS 316 grade for trough and other is SS 304 grade with matt finish.Benefits: 1. Corrugated profile trough size provided-1200mm Long and 2000mm Wide to increase packing capacity. 2. Regulate the gherkin feeding by VFD. 3. Capacity 4000-8000 Kg /Hr. 4. Less Noise.

Best Deals from Filling Machine

Automatic Filling Line

Get Price Quote

We are offering automated filling line. automated filling lines for filling products like pickles, pastes, paints, viscous liquids,powders into containers, jars and bottles. volume and weight based filling systems can be attached. option of lidding, capping sealing available. speeds of up to 40 containers per min.

Volumetric Cup Filler

Get Price Quote

Auger Filling Machine

Get Price Quote

Packaging of our products is accomplished by following stringent quality standards. We have hired a team of professionals who make sure that the entire lot is intricately packed and reaches the destination in the best state. We have trustworthy and well-organized shipping facilities available, along with this, we keep a record of the same as well, and this increases our efficiency and gains the trust of the customers. Features : Pocket friendly prices Easy Maintenance High Durability

Nursery Bag Filling Machine

320,000 Per Piece

1 Piece(s) (MOQ)

Media server & mixer for requirements of nursery. It is suitable for filling bag, trays, and pots. Available in 2 different models. Can be redesigned for your specific requirement. Speciality modular design.

Oil Filling Machine

Get Price Quote

Water Demineralization Plant

65,000 Per Piece

1 Piece(s) (MOQ)

the new “mars aqua dm-xl series” have several user-friendly features and are available in three standard models. de-mineralizes/ de-ionizers (dm plants) are based on ion exchange technology and removes all the dissolved ions present in raw water and gives high purity dm water having low conductivity (

Powder Filling and Compacting Machine

Get Price Quote

Battery Tubular Plate Powder Filling Machine

350,000 - 650,000 Per Piece

01 Piece (MOQ)

Water Demineralization Plant

55,000 Per Piece

1 Piece (MOQ)

Electronic Bagging Machine

Get Price Quote

Electronic Bagging Machine Model 50-BM-01 is a Loadcell based Automatic Weighing Machine and is designed for automatic weighing & filling of free-flowing materials in to open-mouthed gunny bags or HDPE bags from an overhead storage hopper. The machine is of net filling type where in the material is pre-weighed and then discharged into a bag that has been clamped to a Bag Chute. The weight sensing is by Strain gauge based loadcells and measurement and control is through a micro controller based Electronic Control unit (ECU). A hopper, with a pneumatically operated discharge gate, suspended from two shear beam type Loadcells is used to weigh the material fed in to it. A pneumatically operated two position flap gate and the ECU regulates the feeding of the material to the weigh hopper. The flap gate operating mechanism has provision for coarse and fine feed of material. The bag clamp is pneumatically operated and is effected by the operation of a lever switch after positioning the bag on to the chute. The bagging process commences on clamping the bag to the chute. A high resolution Analog to Digital converter employed in the ECU measures and displays the weight digitally. The micro controller on receiving a start command operates the feeder flap to control the feed rate to the hopper in two stages namely 'coarse' and 'fine' feed cycles. The ECU compares the weight detected by the loadcell against a preset value and decides the duration of coarse and fine feed cycles. The feeding is stopped on achieving the preset weight. In-flight correction is provided to achieve accurate weighing. The ECU then discharges the material to the bag, after confirming that the bag is clamped on to the bag chute. The correctly filled bags are released automatically. In case of over or under loading of a bag, an alarm is set and the operator has to release the bag manually. The machine has a robust construction to withstand harsh industrial conditions and is designed such that there are no removable parts, which affects the weighment. This ensures accurate, reliable and consistent operation.

Tea

Get Price Quote

We are rapidly becoming a popular class of teas throughout Karnataka. Teas are noted for their fresh flavor and green character, along with their scientifically proven health benefits. Teas are predominantly produced throughout India different State like south India during a spring growing season that runs from March through May. Tea artisans use various methods of firing the freshly harvested tea leaves to prevent the natural oxidation process and preserve the fresh green aspect of the leaf.We offer high quality tea powders which are made by Fresh Raw Material and are completely free from artificial flavors, Colors, Real Aroma and delicious taste.

Drum Filling Machine

Get Price Quote

Purge Systems

Get Price Quote

Bebco EPS purge and pressurization by Pepperl+Fuchs is a household name in the process automation industry. As the leaders in Purging Technology, we manufacture innovative solutions that are remarkably simple to use and will easily handle just about any application.With Pepperl+Fuchs' Bebco EPS purging and pressurization, you get State-of-the-art solutions based on more than 20 years of experience a family of automatic purge and pressurization systems that make hazardous location protection easy Technical support anywhere in the world Purge and pressurization systems designed according to ATEX direction 949EG, NFPA 496, and ISA 12.4 standards Easy integration compact, low-profile designs that can be internally or externally mounted Automatic temperature and leakage control and alarming User interface with programming to meet most users' demands

Windscreen washer

Get Price Quote

Highly concentrated cleaner additive for the windscreen washer during the summer. Bottle contents of 50 ml will yield 5 litres of cleaning solution. Removes insects, oil, grime, silicone,and dangerous dazzling and greasy films. Compatible with plastics – does not cause tension cracks/dull spots on headlamp diffusers. Also well suitable for XENON headlamps and plastic diffusers in clear glass design. Suitable for fan jet nozzles. Can be mixed with tap water (all hardness degrees).

Industrial Gas Filling Machine

Get Price Quote

Minimum order value Rs. 10 Lakhs and above , This special purpose machine is used to fill the oil and gas in shock absorber. This machine is specifically designed for 6-different shock absorber models. they are yc5, yy4, zen rr, 800 cc rr, wagonr – rr, alto rr. ‘Oil and gas filling machine ‘is used for following purposes. - At riveting position, the component gets plugged partially to press fit. - At sealing position, Oil and gas filing is done. This machine works by pneumatic and hydraulic systems. The oil and gas filling component is placed on component locator, where it is incorporated with load cell and pneumatic cylinder on central slide assembly.

bagging system

Get Price Quote

IPA's bagging machines are extensively used in various industries like spices, coffee, cattle feed,tea, fertilizer, etc. We make both the nett weight bagging machine which is called the pre-weigh & dump machine and also the direct bagging machine.

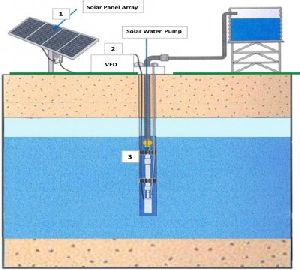

Solar Water Pumping Systems

Get Price Quote

MicroSun solar water pumping solutions provides solution to water supply which are cost effective and will enhance savings of your electricity expenses . Highly efficient VFD will support the pump to lift the water from the source of body. The pumping system is designed with Maximum Power Point Tracking (MPPT) to give the maximum output with the help of MicroSun solar panels. The operation of solar powered pumps are more economical mainly due to lower operational and maintenance cost and has less environmental impact than pumps powered by an Internal Combustion Engine (ICE).

big bag filling machine

800,000 Per Piece

Bag Filling Machine

Get Price Quote

Jumbo Bag Filling Machine

Get Price Quote

The big bag filling machine has been designed to fill even the most difficult to handle materials,using a time proven technique which involves high precision weighing coupled with a truncated pyramid table with vibrators, the filled material is weighed deaerated and densified before leaving the filling station. The ultimate goal is to produce bags that are stable, stackable, safe & easy to handle.Empty bags are mounted by hanging the four loops of the bulk bags on the suspended weigh frames easy to reach posts. The inlet spout is secured to the flared end of the filling head by a slip ring seal. The slip ring allows proper positioning of the liner when used. The bag is then inflated and the weight is tared. The electronics has a inbuilt timer- the duration of inflation is time settable.The filling cycle is controlled by the microcontroller for fast and efficient filling. The set points programmed included the target weight, fast/dribble feed, table up / down, no of cycles, vibration on time etc.Once filling and densification is complete the bag’s inlet spout is released from the filling head and tied off. The bulk bag is dismounted from the machine with a fork lift by simply driving under the pallet / bag,lifting it and backing out. The filling system can be complete with a up stream delivery device and the control system.The filling spout is concentric with 2 nozzles for AIR purging & aspiration systems. Various quantities like 200,500,750 & 1000 kgs can be filled in one cycle The jumbo bag filling machines are custom designed, the machines can be provided with a roller conveyor underneath, once the filling is complete, the bag is lowered onto the roller conveyor & then the conveyor is switched on & thereby moving the bag out of the machine.The jumbo bag which is placed on the pallet can be shifted by using a fork lift. The bag sizes are chosen based on bulk density of the material. Normal bag sizes are 900 x 900 x 1200 mm or 900 x 900 x 1400 mm. the bags are of HDPE material, with plastic liner inside.

Potting Medium Filling Machine

Get Price Quote

One of the major head aches in running a polybag rubber nursery is organising the filling of polybags with the top soil and also carrying this heavy stuff around. Major issues here is the non-availability of the top soil (as it depletes year on year ) and the highly labour intensive soil filling operation. In the case of root trainer, the potting medium can be filled much faster as the quantity to be filled is way too small as compared to ploybag. But in big nurseries even that can be a very time consuming operation given the large quantity of planting materials generated. In such instances our Medium Filling Machine can come handy which can fill about 1000 root trainers in an hour. This a very robust machine which can be operated with minimal man power. Potmed Fillchine operates on single phase electrical energy – no hydraulics nor pneumatics are involved giving rise to very clean and non-messy operations. When it comes to think about the mechanisation of rubber nursery operations, the ready to fill potting medium and the filling machine together take the nursery technology decades ahead.

Big Bag Filling System

Get Price Quote

liquid oxygen pump

Get Price Quote

It is a single acting, Single Cylinder, Horizontal Type, Non Lubricated, Reciprocating Pump, Pumps liquid Oxygen & gasifies in heat exchangers for final filling as gas in cylinders at a pressure of 150 kg/cm2 g. Liquid Oxygen Pump when is Started, the liquid oxygen from the main condenser enters the outer jacket of the pump. Some of this liquid evaporates due to heat produced in pumping and the vapour is passed to the upper column as gas. The major part of liquid oxygen is taken into the pump cylinder and then compressed out by the piston Forward stroke. This high pressure liquid oxygen passes through two non-return valves into the heat exchangers, Gasified and filled in to cylinders through Filling Manifolds. We supply Complete Range of Spares for LOX Pump of all capacities are per customers requirement including S.S. Liner (Size- 20mm to 44mm) S.S. Piston (Size- 20mm to 44 mm) Piston Rings, Guide Ring & Expander Rings. Cross head Gland Packing Safety valves Crank shaft Oil Wiper Rings. Oil Seals. Non-Return Valves of sizes 1/2″, 5/8″ & 3/4″ Connecting rod with bearings. Gudgen Pins. Brass Gland Nut & Cylinder Head Nut

Co2 Filling Machine

Get Price Quote

We are the most prominent manufacture and supplier of an excellent quality Gas Filling Machine. This machine is used to fill liquid carbon dioxide gas in cylinders. Our offered machine is manufactured using high grade raw material under the guidance of expert team of professional which ensure its high strength. We provide this Gas Filling Machine to our valuable clients in various capacities at industry leading price. This machine is useful to fill liquid carbon dioxide into cylinders. Machine has two (2) weighing platforms as standard for easy operation i.e., during filling of cylinder on platform 1, operator can fix the cylinder on platform 2 and once filling is over on platform 1, the machine changes over automatically and starts filling the cylinder on platform 2, hence pressure developed in the line can be avoided .The cycle is repeated for further operation. Some of the features of our carbon dioxide (CO2) gas filling machine are listed as below:

Big Bag Filling System

Get Price Quote

Aircon provides range of bigjumbo bag filling system is a perfect solution for carrying out all such laborious operations and is appropriate for filling and emptying the jumbo bags. The in-built dust extraction of bag handling system helps ensure a dust-free working atmosphere whereas the careful handling of the bag saves it from any kind of damage and allows it to be reused. The handling of bulk bags is a major problem faced in process plants and godown.

Automatic Softdrinks Machines

Get Price Quote

1 Set(s) (MOQ)

We offer automatic soda/softdrinks machines. We are the leading manufacturerssuppliers of fully automatic ro water purification machineries in all sizes like 1000lph to 1,00,000 litreshr capacity with plc systems, it will be available in fully stainless steel and frpf (fibre glass) materials. We also manufacture fully automatic filling machines which ranges from 30bottles per minute tomax 240bpm. We also manufacture fully automatic blowing machines 2 cavity4 cavity which ranges from 2000bottles per hr to max 4000 bottles. We also manufactureset up fully automatic mangojuice processingsoda softdrinks areated drinks lines as well.

Boiler Water Treatment Plant

Get Price Quote

Boiler Water Treatment involves modification of feed water (before Boiler) and inside boiler to avoid potential damage to the boiler and unexpected break downs. This is usually done by pre - treatment plants and with help of boiler water treatment chemicals which modified water parameters for ideal working of boiler.

Multi Head Weigh Filler

Get Price Quote