Linear Vibrating Filling machine for gherkin in Glass jar and Tin Can.

550,000 Per piece

1 Piece (MOQ)

VIBENG designed Linear Vibrating Filling machine to feed Gherkin in linear direction to glass jar or metal tin can in the Gherkin processing packing line. It also suaitable for other vegetable line like Baby corn, Olives, Mushrooms, Whole Gherkins and Hamburger drill chips etc. Vibeng's Design features:1. Fabricated corrugated profile sheet trough.2. Rotatable Discharge chute to accommodate the jar and tin can different height .3. Easy to clean.4. Less maintenance and minimum downtime.5. Drive system mounted at back.6. M.O.C-SS 316 grade for trough and other is SS 304 grade with matt finish.Benefits: 1. Corrugated profile trough size provided-1200mm Long and 2000mm Wide to increase packing capacity. 2. Regulate the gherkin feeding by VFD. 3. Capacity 4000-8000 Kg /Hr. 4. Less Noise.

Water Demineralization Plant

65,000 Per Piece

1 Piece(s) (MOQ)

the new “mars aqua dm-xl series” have several user-friendly features and are available in three standard models. de-mineralizes/ de-ionizers (dm plants) are based on ion exchange technology and removes all the dissolved ions present in raw water and gives high purity dm water having low conductivity (

Best Deals from Filling Machine

liquid oxygen pump

Get Price Quote

It is a single acting, Single Cylinder, Horizontal Type, Non Lubricated, Reciprocating Pump, Pumps liquid Oxygen & gasifies in heat exchangers for final filling as gas in cylinders at a pressure of 150 kg/cm2 g. Liquid Oxygen Pump when is Started, the liquid oxygen from the main condenser enters the outer jacket of the pump. Some of this liquid evaporates due to heat produced in pumping and the vapour is passed to the upper column as gas. The major part of liquid oxygen is taken into the pump cylinder and then compressed out by the piston Forward stroke. This high pressure liquid oxygen passes through two non-return valves into the heat exchangers, Gasified and filled in to cylinders through Filling Manifolds. We supply Complete Range of Spares for LOX Pump of all capacities are per customers requirement including S.S. Liner (Size- 20mm to 44mm) S.S. Piston (Size- 20mm to 44 mm) Piston Rings, Guide Ring & Expander Rings. Cross head Gland Packing Safety valves Crank shaft Oil Wiper Rings. Oil Seals. Non-Return Valves of sizes 1/2″, 5/8″ & 3/4″ Connecting rod with bearings. Gudgen Pins. Brass Gland Nut & Cylinder Head Nut

Windscreen washer

Get Price Quote

Highly concentrated cleaner additive for the windscreen washer during the summer. Bottle contents of 50 ml will yield 5 litres of cleaning solution. Removes insects, oil, grime, silicone,and dangerous dazzling and greasy films. Compatible with plastics – does not cause tension cracks/dull spots on headlamp diffusers. Also well suitable for XENON headlamps and plastic diffusers in clear glass design. Suitable for fan jet nozzles. Can be mixed with tap water (all hardness degrees).

Turn Table

Get Price Quote

Turn Table are used online packing industry to segregate the packets.

Semi Automatic Auger Filler

Get Price Quote

Machine fitted with: 2HP 3phase Motor 1440rpm Auger screw for powder feeding system Clutch and Brake system SS hopper: Capacity 20 kg approx. Auto filling and manual mode with peddle switch Height adjustable pouch stand Contact parts made of SS 304 grade

Battery Tubular Plate Powder Filling Machine

350,000 - 650,000 Per Piece

01 Piece (MOQ)

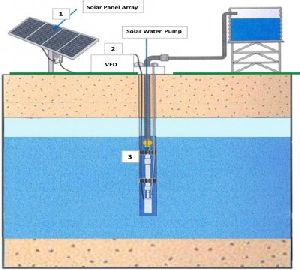

Solar Water Pumping Systems

Get Price Quote

Solar water pumping System provides solution to Agriculture, rural & urban water supply. This system also have facility to run on solar power during day time with sunlight and on conventional power during night. The Unit has Maximum Power Point Trackng (MPPT) technology to harvest maximum power from Solar panel & deliver maximum water thru pump

Volumetric Piston Filler 11

Get Price Quote

We have rapidly emerged as a major manufacturer, exporter and supplier of volumetric piston fillers in bangalore. Offering volumetric piston fillers with a guarantee of quality and efficiency, we cater to a global demand for these fillers. The volumetric piston fillers are pneumatic operated piston fillers and are highly suitable to fill the viscous liquids. features of volumetric piston fillers most suitable for products like pickles, pastes, ghee, oil, inks and paints etc. easy adjustment from 100 ml to 500 ml all contact parts in ss 304 product hopper of 30 liters capacity easy to clean

Nursery Bag Filling Machine

320,000 Per Piece

1 Piece(s) (MOQ)

Media server & mixer for requirements of nursery. It is suitable for filling bag, trays, and pots. Available in 2 different models. Can be redesigned for your specific requirement. Speciality modular design.

Oil Filling Machine

Get Price Quote

Pouch Packing Machine

Get Price Quote

Manufacturers of all kind of automatic PneumaticSemi Pneumatic Form, Fill & Seal Machines for granules, powder, snacks, Liquidpaste, Biscuits, candy, waferskurkure, coffeeTea etc.

Water Demineralization Plant

55,000 Per Piece

1 Piece (MOQ)

Augur Filling Machine with continous band sealer

Get Price Quote

Indus make Augur Filling Machine is ideal for powder non free flowing materials. The Hopper and the machined screws are constructed in SS304 Material. On start command the Augur is switched on and filling of material in to the weigh hopper commences. The moment 90% of the target value is reached the Augur speed is reduced through VFD. On achieving 100% weight the Augur is switched off. The weighed material is discharged through the funnel.Application: Maida, Atta, Chemical powder,etc..

Drum Filling Machine

Get Price Quote

Twin Station Gas Filling Machine

Get Price Quote

Product Description: Minimum order value Rs. 20 lakhs and above ,This machine is used to fill the gas in the shox absorbers after the oil filling by lip opening and filling the gas and also crimping the component once it is filled.

Fully Automatic Filling Machine

Get Price Quote

1 Piece(s) (MOQ)

we are the leading Manufacturers suppliers of fully Automatic Rinsing Filling capping Machines along with Bottle Infeeder aOut feeder conveyor along with Inspection lamp, shrink Tunnel Etc.. we also manufacture Fully Automatic Filling Machines which ranges from 30Bottles Per Minute toMax 240BPM. its suitable for Cold Beverage Filling Hot Filling as well we also manufacture Set up Fully Automatic Mango Juice Processing Soda soft drinks are ated drinks Lines as well.

Solar Water Pumping Systems

Get Price Quote

MicroSun solar water pumping solutions provides solution to water supply which are cost effective and will enhance savings of your electricity expenses . Highly efficient VFD will support the pump to lift the water from the source of body. The pumping system is designed with Maximum Power Point Tracking (MPPT) to give the maximum output with the help of MicroSun solar panels. The operation of solar powered pumps are more economical mainly due to lower operational and maintenance cost and has less environmental impact than pumps powered by an Internal Combustion Engine (ICE).

Bag Filling Machine

Get Price Quote

Electronic Bagging Machine

Get Price Quote

Electronic Bagging Machine Model 50-BM-01 is a Loadcell based Automatic Weighing Machine and is designed for automatic weighing & filling of free-flowing materials in to open-mouthed gunny bags or HDPE bags from an overhead storage hopper. The machine is of net filling type where in the material is pre-weighed and then discharged into a bag that has been clamped to a Bag Chute. The weight sensing is by Strain gauge based loadcells and measurement and control is through a micro controller based Electronic Control unit (ECU). A hopper, with a pneumatically operated discharge gate, suspended from two shear beam type Loadcells is used to weigh the material fed in to it. A pneumatically operated two position flap gate and the ECU regulates the feeding of the material to the weigh hopper. The flap gate operating mechanism has provision for coarse and fine feed of material. The bag clamp is pneumatically operated and is effected by the operation of a lever switch after positioning the bag on to the chute. The bagging process commences on clamping the bag to the chute. A high resolution Analog to Digital converter employed in the ECU measures and displays the weight digitally. The micro controller on receiving a start command operates the feeder flap to control the feed rate to the hopper in two stages namely 'coarse' and 'fine' feed cycles. The ECU compares the weight detected by the loadcell against a preset value and decides the duration of coarse and fine feed cycles. The feeding is stopped on achieving the preset weight. In-flight correction is provided to achieve accurate weighing. The ECU then discharges the material to the bag, after confirming that the bag is clamped on to the bag chute. The correctly filled bags are released automatically. In case of over or under loading of a bag, an alarm is set and the operator has to release the bag manually. The machine has a robust construction to withstand harsh industrial conditions and is designed such that there are no removable parts, which affects the weighment. This ensures accurate, reliable and consistent operation.