Tempering Furnaces

9,000,000 Per Set

1 Set (MOQ)

ageing furnace

Get Price Quote

Solutionising and Ageing furnace applications from HIGHTEMP provide pit type and continuous type installation for Aluminium components. Features Custom built design Production rate : 250kg to 1000kg gross 250 kghr to 500kghr- continuous type Continuous furnaces can be designed for water quenching andor air quenching Fully automated, PLC controlled operations Thyristors with PID temperature control

Best Deals from Furnaces

continuous furnaces

Get Price Quote

Production capacity 150kghr to 400kghr Operating temperature up to 950oC Sophisticated controls including SCADA & Data Acquisition can be offered Option for Endothermic gas or Nitrogen-Methanol system as atmosphere Option for Gas fired or Electric heating with Radiant tubes Fully automatic, PLC controlled closed loop system Robotic charge handling system for Press Quenching can be offered Ability to process large numbers of different components Modular designs for flexibility and ease of maintenance Silicon carbide skid rails for smooth long lasting movement of charge Pneumatically operated door systems for positive sealing Pusher mechanism designed for heavy loads Automatic adjustment of stroke length to compensate for thermal expansion

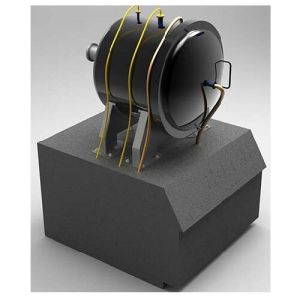

vaccum furnace

4,000,000 Per Piece

ARC remelting furnace

Get Price Quote

HHV has attained the level of expertise in design, developing vacuum technology based equipment, quality in par with the international standards. With its 5 decades of expertise and continuous improvement in design, development and manufacturing variety of vacuum beat treatment and brazing furnace led HHV as one of the leading global player. One of its recent exports is a vacuum arc re-melting furnace to Russia. Vacuum arc re-melting(VAR) is a melting process for production of metal ingots with elevated chemical and mechanical homogeneity for highly demanding applications. VAR is widely used to improve the cleanliness and refine the structure of standard air-melted or vacuum induction melted ingots, and then called consumable electrodes. VAR steels and super-alloys as well as titanium and zirconium and its alloys are used in a great number of high integrity applications where cleanliness, homogeneity, improved fatigue and fracture toughness of the final product are essential. Aerospace, power generation, defense, medical and nuclear industries rely on the properties and performance of these advanced re-melted materials.

Wire Annealing Furnace

650,000 Per Piece

Sintering Furnace

750,000 Per Piece

Sanitary Napkin Burning Furnace

4,999 Per Piece

1 Piece(s) (MOQ)

Vacuum Heat Treatment Furnace

200,000 Per Piece

vacuum furnaces

Get Price Quote

We are an eminent and leading trader of Vacuum Furnaces

Tempering Furnaces

Get Price Quote

Backed with a team of professionals and experts, we are into offering Tempering Furnaces in the industry. These Tempering Furnaces that we offer are manufactured from highly corrosion resistant materials. Further, these Tempering Furnaces are highly energy efficient in nature. Features: Smooth performance Longer operational life Require less maintenance

Vacuum Furnace

Get Price Quote

INDVAC has designed and supplied various size of Vacuum Furnaces for special applications like, Vacuum Brazing, Annealing, Hardening, Tempering, etc. meeting to the customer requirements. INDVAC and Products are worldwide recognized for manufacturing and supplying superb quality Vacuum Furnaces. Our Industrial Vacuum Furnaces are made using the genuine raw material in order to meet international standards of high performance. These Pressure Vacuum Furnaces contain advanced features making them widely adaptable to cater to various requirements of customers.

Industrial Furnaces

Get Price Quote

we are offering Industrial Furnaces. Therelek is one of the leading manufacturers & suppliers of Industrial Furnaces from India.

Continuous Roller Hearth Furnaces

Get Price Quote

The Mesh Belt Conveyor Furnace has been fabricated out of top notch quality raw materials that we have procured from our trusted vendors. They are furnished with brick refractory or molded ceramic fiber insulation, that is lighter, has less thermal mass, and lower thermal conductivity than conventional brick refractory. Application Annealing, Normalising, High temperature tempering, Bright hardening with integral quench facility.. Features Controlled atmosphere operation, Automatic operation with Programme Logic Control. Capacity To suit (custom-built) user’s requirement Version: Gas/ Electric-heated.

continuous furnaces

Get Price Quote

Therelek’s standard pusher type continuous furnace operate up to 1800°C. A multi-zone control environment is present in continuous high temperature furnaces, often with a single pre-heating zone, followed by multiple heating zones and then cooling zones before exit.

nitriding furnace

Get Price Quote

Nitriding furnace of Heat Treatment Machines and supplying Nitriding Furnaces. Beginning with the development of a range of gas nitriding technologies we have broadened our scope of activity beyond gas nitriding to include other heat treating processes and product lines.

Laboratory Furnace

Get Price Quote

Muffle Furnace

35,000 Per Piece

Tube Annealing Furnace

Get Price Quote

pusher furnaces

Get Price Quote

Therelek’s standard pusher type continuous furnace operate up to 1800°C.Higher temperature requirements are also encouraged which require process specific design. A multi-zone control environment is present in continuous high temperature furnaces, often with a single pre-heating zone, followed by multiple heating zones and then cooling zones before exit. Due to the high temperatures involved most of these furnaces operate under controlled and protective atmospheres, with inert gases such as nitrogen and argon used for initial purging, and gas mixtures or gases like cracked ammonia or hydrogen or endogas used to create a suitable atmosphere as per process parameters.